What happens if mineral wool gets wet?

Water strikes fear into many insulation users, making us worry about rot, mold, and ruined material. But is getting wet really a disaster for mineral wool insulation?

If mineral wool gets wet, it usually dries out without losing its insulation abilities. Its structure repels water, so it does not absorb much or let mold grow.

Water and insulation usually don’t mix, but mineral wool is different. Unlike other materials, mineral wool can handle some moisture. In this post, I explain what really happens when mineral wool gets wet, and why these properties matter so much for those responsible for long-term performance and safety.

Is mineral wool water resistant?

Most people worry that insulation soaks up water like a sponge, leading to ruined tank performance and unexpected maintenance. I used to feel the same way.

Mineral wool is water resistant. Its fibers do not soak up water; instead, liquid stays on the surface and drains away, keeping the insulation dry and effective.

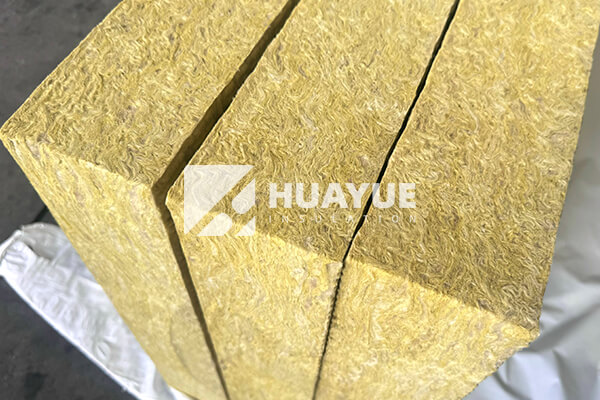

Here’s why mineral wool stands out. The fibers inside the insulation create tiny spaces. These spaces slow down the movement of liquid water. When water hits mineral wool, it beads up and runs off, just like rain on a good raincoat. This is called water repellency, and it is built into the structure of each slab. I know from my work that water resistance matters because waterlogged insulation often leads to corrosion or poor performance in other materials. Mineral wool, especially ThermRock GEN from HUAYUE Group, resists this risk. Even if the surface gets damp, the core stays dry. This is crucial for applications like chemical tanks, where water exposure happens but long-term stability is demanded. During packaging and storage, my team uses shrink-wrapped polyethylene to create another layer of protection, proving that good design starts from the factory floor.

| Feature | Mineral Wool | Traditional Fibrous Insulation |

|---|---|---|

| Water Absorption | Minimal to none | Moderate |

| Water Beading | Yes | No |

| Risk of Rot | None | Possible |

| Handling When Wet | Dries Out, Reusable | Damaged, May Need Replacing |

Can mineral wool be exposed to weather?

Outdoor exposure can ruin many insulation types, turning good material into a maintenance headache. I have seen insulation failures caused by nothing more than a leaky roof or burst pipe.

Mineral wool can be temporarily exposed to weather, but long-term outdoor use needs proper protective facings to guarantee continued performance.

There are times when insulation sits outside—maybe while waiting to be installed, or during unplanned delays. With mineral wool, you get a bit of leeway. Brief exposure to rain or snow will not break it. The water repellent structure lets most water roll off, and any remaining moisture dries quickly with air circulation. However, no insulation can last forever in harsh weather without a cover. Over weeks or months, repeated weather cycles will wear down even the best products. In my plant, I always insist on facings—like reinforced foils—for outdoor installations. These keep water out and hold the insulation together. HUAYUE offers fabrication services so each slab gets the right finish for its intended exposure. For best results, protect mineral wool from direct sun and steady rain, and always use approved facings for permanent outdoor use. The ability to be handled and installed easily gives another benefit—less time spent exposed.

Does mineral wool rot?

Many people think all insulation eventually rots. I have faced many questions about how to stop this ruin, especially in humid environments or near chemicals.

Mineral wool does not rot. It is made from volcanic rock and recycled slag, so it stays stable and does not degrade even if it is damp for a while.

Rot happens when organic material meets moisture and microbes. Traditional organic insulators can break down, shrink, or turn soft. This leads to sudden failures and bad smells. But mineral wool works differently. The rock fibers inside are inert—they don’t react unless faced with temperatures so high they’d melt steel. Water alone cannot break them down. No matter how humid the environment, mineral wool keeps its shape and structure. That’s why I trust it in chemical plants where steam, spills, and high humidity can create rot nightmares for other materials. In my experience with HUAYUE’s ThermRock GEN, I have never seen mineral wool slabs disintegrate, even when left damp for days before final installation. If you want insulation that outlasts the building, or the tank itself, mineral wool is the right bet.

Will mold grow on mineral wool insulation?

Mold is a silent killer for insulation. Plant managers and engineers ask me how to prevent mold inside their tanks almost every week.

Mold will not grow on mineral wool insulation because it does not offer food for fungi, bacteria, or mildew. Its inorganic nature keeps microbial problems away.

For mold to spread, it needs warmth, water, and food. Some insulation materials provide all three. But mineral wool contains no organic matter, so fungi can’t use it as a food source. Even if water gets onto or into the slab, it drains or dries out quickly, so conditions for mold never last long. This is different from organic insulations, which can turn into breeding grounds for spores and bacteria. In facilities like mine, where controlling contamination matters, this property is not just a bonus—it is essential. We avoid sick building syndrome, and there are fewer odor complaints. I tell my teams that using mineral wool also lowers maintenance costs, since there is no need to replace moldy insulation. By choosing certified and SGS-validated products like HUAYUE’s ThermRock GEN, we add another layer of confidence about indoor air quality.

Conclusion

Mineral wool stays strong, even when wet. It resists water, mold, and rot, keeping performance high and maintenance low in any industrial setting.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions