What is a batt of insulation?

Most people wonder about insulation when they feel drafts or see rising energy bills. But what exactly is a batt of insulation?

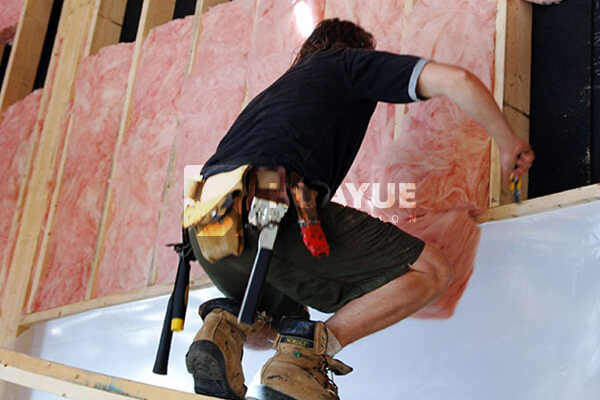

A batt of insulation is a pre-cut, rectangular panel made from materials like fiberglass, rock wool, or mineral wool, designed to fit snugly between wall studs, ceiling joists, or floor beams to reduce heat transfer in buildings.

If you are trying to make your home or project more energy-efficient, knowing about batt insulation is essential. I have seen many misunderstandings about what a batt is, especially when comparing it to other forms of insulation, such as rolls or loose-fill. If you are looking for ways to control temperature, manage sound, or meet building codes, getting clear on the basics of insulation batts is a smart place to start.

How is batt insulation made and what is it made of?

When you are faced with choosing insulation, you might see the term “batt” and feel uncertain. Why is it called a batt, and what materials are used to make it?

Batt insulation is made by weaving or binding together fibers—usually fiberglass, rock wool, or mineral wool—into pre-formed rectangular sheets. These batts are cut to fit standard spacing between framing members, making installation straightforward.

Batt insulation forms when loose fibers are gathered and bonded into thick mats. These mats are then cut into standard sizes, which makes them easy to install between studs or joists in walls, floors, or ceilings. Mineral wool and rock wool batts are often denser and heavier, offering slightly better fire resistance and sound control than fiberglass. Some batts come with a facing, like kraft paper or foil, which acts as a moisture barrier. The facing is always installed toward the warm side of the wall. Below is a table showing the main types of batt insulation materials and their key properties:

| Material | Main Benefit | Fire Resistance | Moisture Resistance | Typical Applications |

|---|---|---|---|---|

| Fiberglass | Low cost | Moderate | Low | Walls, attics, ceilings |

| Rock Wool | High fire rating | Excellent | High | Commercial/industrial buildings |

| Mineral Wool | Soundproofing | Excellent | High | Mechanical rooms, exterior walls |

Understanding what a batt is made of helps you pick the right type for your project. This can impact both performance and safety for years to come.

Where is batt insulation most often used?

Finding the right spot for insulation can feel overwhelming. Where does batt insulation work best?

Batt insulation is most often used in walls, attics, ceilings, and floors of homes and buildings. It fits easily between standard framing sizes to stop heat loss and save energy.

I have installed batt insulation in almost every part of a building. The most common areas are in wall cavities, where it fits between 16-inch or 24-inch spaced studs. Ceilings and attics, especially those with flat joists, are also perfect for batts. In floors above unconditioned spaces like crawl spaces or garages, batts prevent cold air from cooling the floor above. Using batt insulation in these standard spaces is both cost-effective and efficient. Table below explains where it makes sense to use batt insulation:

| Building Area | Reason to Use Batts | Typical R-Value Range |

|---|---|---|

| Exterior Walls | Prevents heat loss/gain | R-13 to R-21 |

| Attic Floors | Stops rising heat from escaping | R-30 to R-49 |

| Basement Ceilings | Keeps rooms above warmer | R-19 to R-30 |

| Crawl Space Floors | Blocks cold air from entering living space | R-19 to R-30 |

Knowing these locations means you can maximize comfort while minimizing energy costs.

What are the main advantages and disadvantages of batt insulation?

Choosing insulation can lead to confusion. What should you weigh when it comes to batts?

Batt insulation is affordable and easy to install, making it popular for many projects. But it can leave gaps if not properly fitted, and some materials can cause itching or irritation during handling.

From my experience, many people like batt insulation because it often needs no special tools for installation. You can cut it with a utility knife and place it between framing members. This saves labor costs. Batts also come in a range of thicknesses and R-values to suit different climates. However, it is important to install batts carefully. Gaps, compression, or misalignment can lower the insulation’s effectiveness. Fiberglass batts may irritate your skin, eyes, or lungs if you do not wear protection. Here is a quick breakdown:

| Pros | Cons |

|---|---|

| Easy DIY installation | Prone to gaps if poorly fitted |

| Widely available | Fiberglass can irritate skin |

| Offers various R-value options | Not as effective in irregular spaces |

| Low material cost | Needs vapor barrier in moist climates |

These advantages and disadvantages help you decide if batts are right for your project or if another form of insulation is better.

Conclusion

Understanding batt insulation means you can make smarter choices to improve comfort and energy efficiency in any project.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions