What insulation is better than mineral wool?

If you are checking for better thermal insulation, mineral wool might not always be your best option. Let’s explore the alternatives and how the right choice depends on your specific needs.

Mineral wool is highly effective for fire resistance and soundproofing, but foam glass and closed-cell materials often offer superior moisture resistance, durability, and lower maintenance for tanks or when water absorption is a concern.

I have often compared choices between mineral wool, fiberglass, and foam glass with customers like Hans Müller. Each material has a unique set of strengths and weaknesses. Costs, safety, and environment requirements matter. To make the right decision, you have to look at all sides. Sometimes it’s not about which insulation is better in every way, but which fits the project best.

What is mineral wool insulation used for?

Many think of mineral wool as the default material for industrial and building insulation. People often say it is strong and safe.

Mineral wool is mainly used for thermal, fire, and acoustic insulation in buildings, tanks, and industrial plants. Its high melting point and non-combustible nature make it suitable where fire safety is a top priority.

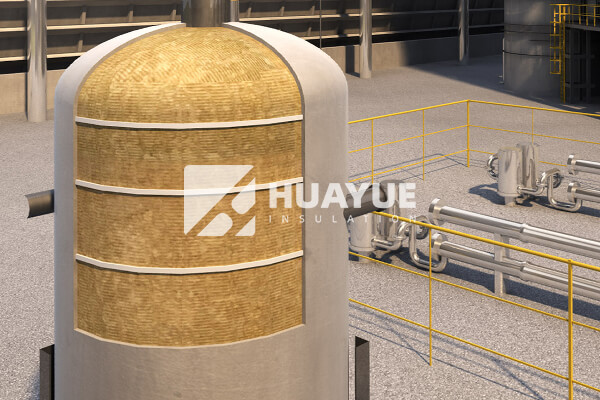

I have seen mineral wool insulation installed in walls, roofs, pipes, ovens, and around industrial tanks. Its natural fibers work well to stop heat transfer and block out noise. It shrugs off high temperatures and does not burn. This made it very popular for safety-focused projects. Engineers in chemical plants, like Hans, rely on this when safety standards are strict. But mineral wool absorbs water and can promote corrosion under insulation (CUI) in metal tanks. This limits its long-term use where moisture is a problem.

| Application Area | Performance Benefit | Limitation |

|---|---|---|

| Industrial tanks | Good fire resistance, ease of install | Water absorption, risk of CUI |

| Building envelope | Good thermal & acoustic performance | Heavy, needs extra handling |

| Pipes and ducts | Good coverage for curves | Not weatherproof without jacket |

| Ovens, furnaces | Handles high heat | Not suitable for wet locations |

Is mineral wool better than fiberglass?

This question comes up in almost every project meeting. One material does not always win over the other.

Mineral wool has better fire resistance and acoustic properties. Fiberglass costs less and is lighter, but both materials offer good thermal insulation and similar R-values for most construction uses.

When I speak with plant engineers or builders, several differences stand out. Mineral wool holds its shape well, so it fits snug around tanks and pipes. It usually resists high heat more effectively. Fiberglass, though, is much lighter. You can install it faster and carry it easily. It is less expensive, which helps for big projects but breaks down at lower temperatures and is less resistant to fire. Both can soak up moisture unless protected, but fiberglass is slightly more likely to slump or break if handled roughly.

| Property | Mineral Wool | Fiberglass |

|---|---|---|

| R-value (per inch) | 3.0 – 3.3 | 2.9 – 3.8 |

| Fire Resistance | Excellent, non-combustible | Good, but melts at lower temps |

| Water Absorption | Moderate, needs protection | Moderate to high, needs vapor barrier |

| Weight | Heavier | Lightweight |

| Cost | Higher | Lower |

| Acoustics | Very effective | Good, but less than mineral wool |

| Durability | High, keeps shape | Moderate, can slump |

Neither one is perfect. If you need the best fire safety and sound control, mineral wool comes out ahead. For budget projects or easier installation, fiberglass makes sense. In my experience, we have to match the insulation to the job, not rely on a simple “better or worse” label.

What type of insulation is mineral wool?

Many people ask me, “Is mineral wool a type of foam or a special fiber?” This confuses even some professionals.

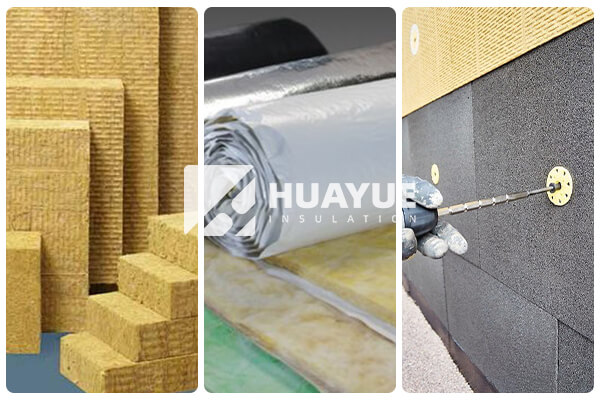

Mineral wool is a type of fiber insulation made from molten rock or slag. It comes in forms like batts, boards, and loose-fill, designed to trap air and stop heat and noise movement.

When you see mineral wool at a job site, it looks a bit like thick felt or cotton candy. It is made by spinning lava or blast furnace slag into fibers, then compressing those fibers into mats or boards. The air pockets inside the fibers help keep heat from moving through. Mineral wool is not foam—it is a solid mass of mineral fibers held together by a binder. It does not burn, which sets it apart from many other insulations. At our manufacturing plants, I often show new engineers how mineral wool can be shaped for many uses. It insulates roofs, walls, tanks, ovens, and even ship hulls because of its strong fire performance and sound-dampening qualities.

| Mineral Wool Form | Common Use | Thermal Value | Fire Resistance | Water Absorption | Install Method |

|---|---|---|---|---|---|

| Batts & Blankets | Walls, roofs, tanks | High | High | Moderate | Laid or stuffed |

| Rigid Boards | Wall exteriors, tanks | High | High | Moderate | Fixed/secured |

| Loose-fill | Attics, cavities | Moderate | High | Moderate | Blown in |

Conclusion

The best insulation depends on your needs. Mineral wool offers top fire safety and noise control, but other materials may suit wet or special environments better.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions