What Does Density Mean for Rock Wool Insulation?

If you are in charge of insulation projects, have you ever questioned how much density matters when picking rock wool? It could make or break your long-term investment.

The density of rock wool insulation affects how well it insulates, its strength, and its fire resistance. High-density rock wool is often used for better performance in demanding environments.

We always want the insulation material to last as long as possible and save trouble down the line. Understanding why density matters can set you up for success. Next, we will look into exactly what rock wool insulation density is and why you should care.

What is the density of Rock wool insulation?

If you search for the right density, it often gets confusing. Many insulation suppliers give different numbers.

The density of rock wool insulation usually ranges from 40 to 200 kg/m³ for boards, 50 to 140 kg/m³ for rolls, and 80 to 160 kg/m³ for pipe sections.

When we look deeper, density is just a measure that tells us how much material there is in a certain volume. The unit is usually kilograms per cubic meter (kg/m³). Boards designed for building facades and mechanical equipment often pick a density of 80-200 kg/m³, which gives good strength and fire protection. Rock wool rolls are lighter, running from 50-140 kg/m³, which helps cover large, less-loaded areas like roofs. Pipe insulation often lands between 80-160 kg/m³ because it needs enough strength to keep its shape but also needs to wrap easily. Think of it like comparing a hard foam cup to a heavy-duty ceramic mug—they both hold liquid, but their weight (and use) are very different.

Here is a simple table for HUAYUE’s product range:

| Product Type | Typical Density Range (kg/m³) |

|---|---|

| Rock wool board | 40–200 |

| Rock wool roll | 50–140 |

| Rock wool pipe | 80–160 |

The right pick comes down to where it will be used. High-density isn’t always better, but it’s needed where strength and fire resistance are the main worries.

What is the most dense Rock wool?

If you wonder how dense rock wool can get, it is a fair question, especially for tough industrial jobs.

The most dense rock wool insulation can exceed 200 kg/m³, but in standard use, 200 kg/m³ is often the upper limit for boards in industrial and fire-protection scenarios.

Why do people need high-density rock wool? High-density rock wool is pressed much tighter. This gives it a solid feel. Factories choose it for mechanical rooms, tank walls, or very strict fireproofing jobs. I have seen panels at the maximum density used in cryogenic tanks, where shifting or compressed insulation would spell disaster over time. The higher density means less empty space inside, which lowers the chance of air or water sneaking through. But it also makes the panels heavier, pricier, and sometimes harder to handle.

High-density boards (like 180–200 kg/m³) are best when you need your insulation to be strong, resist impact, or hold up under weight. You might not need them everywhere. Medium density is often fine for walls or loose spaces. Always match the demand of the project to the density of the material. Otherwise, it might just be extra cost and weight for no added value.

What is the downside of Rock wool?

No product is perfect. Rock wool has a lot going for it, but it is not all sunshine.

Rock wool’s downsides include its weight at higher densities, cost, and potential for irritation during installation if not handled properly.

Let’s talk real-life. When I first started specifying rock wool, I loved its fireproof and water-resistant properties. But during a big retrofit, some workers complained about an itchy feeling on their skin and in the air—rock wool fibers. If you do not suit up, the job can get very uncomfortable. Also, high-density rock wool is heavy compared to other insulation materials. It may need more support structures. This adds to installation cost and complexity.

Here is a quick pro/con table to break it down:

| Benefit | Downside |

|---|---|

| Fire resistant | May cause skin irritation if not protected |

| Won’t absorb water | Heavier than some alternatives at high density |

| Good soundproofing | Higher cost |

| Lasts long | Needs careful handling during installation |

Always weigh these factors when choosing rock wool. Plan extra safety and training for your team to handle the material right.

How to check the density of ROCK WOOL?

It is easy to get lost in specifications and forget the basics—how do you actually check rock wool’s density?

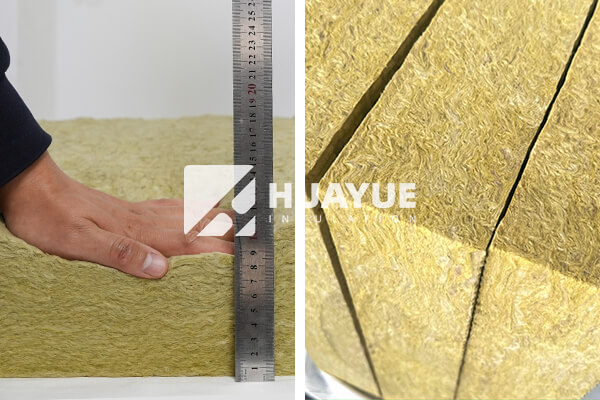

To check rock wool’s density, measure its weight and volume, then divide weight by volume (Density = Weight ÷ Volume). The result is in kg/m³.

Testing density is simple: take a sample of known size, put it on a scale, and write down the weight. Then, calculate its volume (length × width × thickness, in meters). Divide the weight by the volume. This gives you the density in kg/m³. For example, if a board is 1m × 1m × 0.05m (0.05m³) and weighs 7.5kg, its density is 150kg/m³.

I’ve always made sure every batch from our plant meets the standards this way before we send it out the door. It forces us to catch errors and explains why our products are so consistent.

You do not always need fancy tools—just basic math and careful record-keeping will keep your insulation performing as promised.

Conclusion

The density of rock wool insulation matters for strength, fire resistance, and long-term performance. Choosing the right density means fewer problems and a longer-lasting solution.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions