High Performance Mineral Wool Insulation: What Do You Really Need to Know?

When you pick the wrong insulation, you get high energy bills, messy repairs, and extra stress. High performance mineral wool insulation helps avoid these headaches with its durability and reliability.

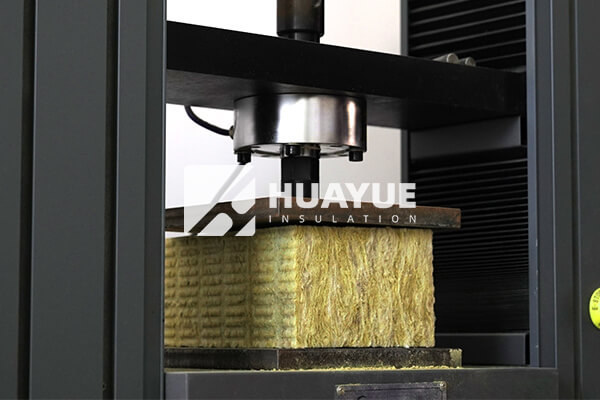

Mineral wool insulation, including rock wool, offers excellent thermal protection, fire resistance, and moisture resistance. It performs well in demanding environments, making it a top choice for industrial and commercial applications.

If you are thinking about your next insulation solution, you need to understand the details about mineral wool—how it behaves in real-world conditions and what sets it apart from other options. Let’s go deeper into what happens if mineral wool gets wet, how it compares to rock wool, and what its long-term performance looks like. I will also answer common questions about vapor barriers. Each point will help you make a better decision for your facility.

What Happens if Mineral Wool Insulation Gets Wet?

No matter how careful you are, insulation sometimes gets wet. If you are using mineral wool, you may worry it will lose performance, allow mold, or speed up corrosion. This never brings peace of mind.

When mineral wool insulation gets wet, it generally sheds water and dries out quickly. Thanks to its water-repellent fibers, it keeps most of its thermal and fire resistance, as long as it is not left damp for long stretches.

Mineral wool has a unique structure. Its fibers are non-hygroscopic. This means they do not soak up water the way organic materials do. If rain or leaks hit mineral wool, most of the water runs off. The small amount that might linger between fibers quickly evaporates. That reduces the risk of mold or material breakdown.

I once saw a large tank in a coastal area that had a minor leak in the cladding. We expected damage, but the mineral wool dried soon after repairs. Its R-value stayed stable, so no re-insulation was needed. However, it is important not to ignore water problems. Long-term exposure can still hurt performance, especially if dirt collects and embeds in wet fibers. In most real-world plant situations, though, quick attention means mineral wool insulation bounces back better than old-fashioned organic or cellulose-based insulation.

| Mineral Wool | Organic Insulation | Foam Plastic Insulation | |

|---|---|---|---|

| Reaction to water | Sheds water, dries fast | Soaks up water | Traps moisture inside |

| Mold growth | Unlikely | Likely | Possible |

| R-value loss | Minimal if dried fast | High | Medium |

| Permanent damage | Low | High | Medium |

Is There a Difference Between Rock Wool and Mineral Wool?

When choosing insulation, terms like "rock wool" and "mineral wool" sound confusing. You may wonder if one is stronger, or if it’s all marketing—they aren’t always used correctly.

Rock wool is a type of mineral wool, made mainly from basalt rock and slag. "Mineral wool" is a broader term and also covers slag wool and glass wool. While their properties overlap, rock wool stands out with higher density and better fire performance.

Both rock wool and mineral wool insulations share many strengths. They resist fire, damp, and pests. But rock wool, made from volcanic rock, survives at even higher temperatures. This makes it popular in places that demand extreme fire ratings, like chemical plants or refineries.

I have specified both types for tanks and piping. In high-temperature lines, I often choose rock wool for its extra heat tolerance. For general wall or ceiling panels, mineral wool might do the job at a lower price. The right choice depends on your application, budget, and risk level.

| Attribute | Rock Wool | Mineral Wool (broad) | Glass Wool |

|---|---|---|---|

| Raw material | Basalt, slag | Basalt, slag, glass | Recycled glass |

| Density | Higher | Medium to high | Lower |

| Fire resistance | 1000°C+ | 750–1000°C | 350–600°C |

| Typical uses | Process industry, tanks | Buildings, piping | Buildings, low-temp |

What Is the Life Expectancy of Mineral Wool Insulation?

You want insulation to last for decades, not a few years. Downtime, replacements, and production loss are real costs that eat into your bottom line.

Properly installed and maintained, mineral wool insulation lasts 30 to 60 years. Its inorganic fibers resist decay, weathering, and fire better than many alternatives, ensuring long-term thermal and safety benefits.

Mineral wool’s durability is part of what drove me to recommend it for plant upgrades. In a chemical storage facility I worked with, panels insulated 25 years earlier still tested near their original density and R-value. There were no major signs of sagging, shrinkage, or water damage. The key factors are moisture protection, robust cladding, and regular inspection.

Environments that are extreme—like outdoor tanks or cryogenic applications—test an insulation material’s lifespan. Here, mineral wool outperforms most organic or plastic insulations, because its fibers do not rot or break down under UV or temperature stress. Preventing damage to outer coverings is the real challenge. Once the shell is kept intact and minor problems are handled early, mineral wool offers a reliable, long-term solution with little performance loss over decades.

| Insulation Type | Life Expectancy | Key Factors for Longevity |

|---|---|---|

| Mineral Wool | 30–60 years | Good cladding, dry conditions |

| Glass Wool | 20–40 years | Less tolerant of moisture |

| Plastic Foams | 10–30 years | UV and moisture sensitive |

| Organic Materials | 5–20 years | Degrade under moisture, pests |

Does Mineral Wool Insulation Need a Vapor Barrier?

You may hear conflicting advice about vapor barriers. Going without could mean future headaches like condensation or corrosion. Too much protection adds costs or traps moisture—so what’s right?

A vapor barrier is often recommended with mineral wool insulation, especially in humid or cold climates, or where there is a risk of condensation. It mostly helps protect against moisture ingress and corrosion under insulation.

When I consult on tank insulation, I look at ambient humidity, temperature differences, and the building’s airflow. For cold tanks or those with vapor drive from outside in—like in northern Europe—an external vapor barrier keeps water vapor from penetrating and reaching cold surfaces. This helps stop CUI and keeps thermal performance steady over time.

In some dry, hot areas, or where the insulation is used purely for fire resistance or sound absorption, a vapor barrier may not be required. But for long-lasting thermal efficiency and the best corrosion protection—especially in high-value tanks—a professionally installed vapor barrier with mineral wool insulation is a good investment.

| Situation | Vapor Barrier Needed? | Reason |

|---|---|---|

| Cold tank, humid climate | Yes | Prevents condensation, CUI |

| Warm, dry environment | No | Low vapor drive risk |

| Fire or acoustic use only | Optional | Moisture not a concern |

| Outdoor application | Yes | Weatherproofing, condensation mix |

Conclusion

High performance mineral wool insulation stands out for long life, water resistance, and fire safety. Know its limits, use vapor barriers where needed, and your tanks will stay protected for decades.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions