Acoustic Mineral Wool Cavity Insulation: The Ultimate Solution for Soundproofing?

Loud indoor noise can disturb work, sleep and peace at home. Finding the right cavity insulation stops sound at the source and keeps rooms quiet and comfortable.

Acoustic mineral wool cavity insulation works because its dense, open-fiber structure absorbs sound waves, reduces airborne noise, and adds thermal value. It is now widely chosen for cavity walls in both homes and industrial applications.

Choosing the right soundproofing insulation can feel confusing. Sometimes you get lost in technical data and marketing claims. I have seen projects stall when bad insulation leads to disappointing noise reduction or mold. But mineral wool, especially rock wool, solves many of these problems with its proven structure and long service life. Step by step, I will explain why it remains my go-to recommendation for cavity wall sound insulation.

What is the best insulation for acoustic cavity walls?

Noisy neighbors, busy streets, and clattering pipes can turn any space stressful. Many products promise quiet, but few deliver strong and lasting acoustic protection.

For best performance in cavity walls, I recommend dense mineral wool insulation like rock wool or glass wool. These materials trap sound in their fibers and prevent most airborne noises from passing through. Their effectiveness, fire resistance, and moisture tolerance make them the top choice in many environments.

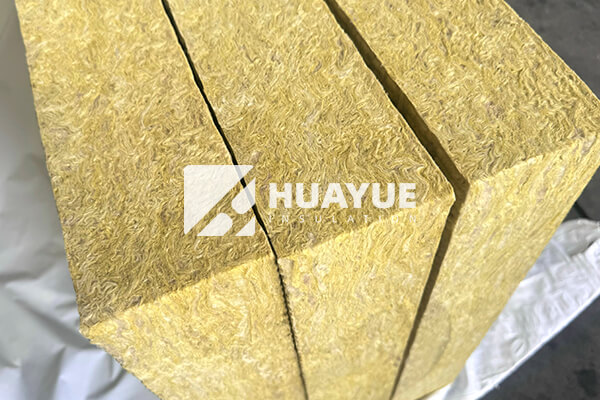

Let’s break down what makes insulation "best" for acoustic cavity walls. Mineral wool—either glass or rock wool—is packed with interwoven fibers. This structure forces sound waves to lose energy as they try to move through. Where foam or rigid panels sometimes bounce or transmit sounds, mineral wool turns noise into harmless heat. Thickness and density matter: deeper and denser slabs trap more sound. For walls between rooms, stairways, or meeting spaces, a 50–100mm thick slab rated for acoustic performance brings noticeable peace. Sound Transmission Class (STC) and Noise Reduction Coefficient (NRC) metrics provide quick comparison at a glance. Mineral wool consistently achieves high values in both. It also fits snugly, resisting gaps that can let noise slip by. Over decades of work, I have noticed fewer call-backs and noise complaints when mineral wool is used, especially in factories and apartments.

| Insulation Type | Typical STC Rating | NRC (absorption) | Water Resistance | Fire Resistance | Lifespan |

|---|---|---|---|---|---|

| Mineral wool (rock wool) | 50+ | 0.9+ | High | A1 (noncombustible) | 30+ years |

| Fiberglass | 45-50 | 0.9 | Medium | A1 | 20–30 years |

| Foam board (XPS, PUR) | <40 | 0.3–0.5 | Medium-high | Varies | 20–25 years |

| Cellulose | 44–49 | 0.8 | Low | B (flammable) | ~20 years |

Is rock wool good for acoustic insulation?

Noisy machines or voices in the next room create real headaches. Traditional materials promise silence but often disappoint. Does rock wool offer real relief?

Yes, rock wool is very effective for acoustic insulation. Its high-density, fibrous structure allows it to trap sound energy and prevent noise from moving through cavity walls, ceilings, and floors.

I have seen rock wool excel in many industrial plants, offices, and homes. The key is its non-directional fiber content. When sound hits the rock wool, the energy spreads out and is absorbed, not reflected. Unlike some foam boards that can make noise sharper or bounce it into odd corners, rock wool “deadens” sounds, especially voices, footsteps, machine rumbles, and HVAC noise. It keeps meeting rooms private and factory floors quieter. Besides sound absorption, rock wool also provides high fire safety and isn’t eaten away by mold or pests. In many cold or wet climates, this extra protection makes a big difference over decades. Fitting rock wool slabs well, and ensuring no gaps, brings out the best in its acoustic properties. Even after 10 or 20 years, I have found rooms insulated with rock wool still perform as well as the day they were installed.

Can you put rock wool in a cavity?

Many worry that the wrong insulation in a wall cavity can cause dampness, fire risks, or poor sound control. Can rock wool really fit and perform in these spaces?

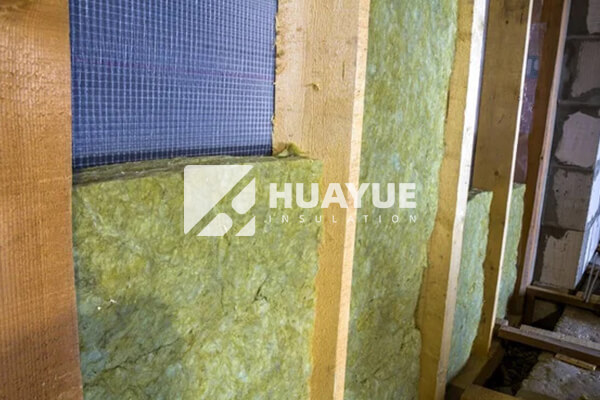

Yes, rock wool is designed for cavity use. Its dimensional stability prevents sagging or slumping, filling voids completely to stop both noise and energy leaks.

In practice, I always specify cavity-grade rock wool for new builds and retrofits. It is made as slabs or rolls that squeeze easily into standard wall and floor cavities. After cutting to length, the slabs press in snugly, holding their shape against framing. The dense, flexible structure means rock wool will not settle over time or leave paths for unwanted air and noise. When I visit completed sites years later, the insulation is usually exactly where it started, still blocking and absorbing noise. For wet or humid environments, rock wool’s mineral makeup makes it water repellent and immune to mold and rot. At the same time, it allows water vapor to escape, helping walls breathe and stay dry. Fire safety regulations are stricter than ever, especially in industrial settings. Here, rock wool’s A1 fire-rated performance adds peace of mind and helps with code compliance.

Is mineral wool acoustic insulation?

Confusion often arises when talking about mineral wool versus other wools or foams. Does mineral wool really serve as true acoustic insulation, or is it just for heat retention?

Mineral wool is a top-grade acoustic insulation. It is made for controlling sound transmission and absorption in walls, ceilings, and industrial applications.

The term “mineral wool” includes both rock wool and glass wool. Both types are well-known for thermal protection, but their real strength lies in acoustic performance. I have worked on many projects using these both in offices to stop voices carrying, and in chemical plants to reduce noise from pumps and turbines. Their dense, open structure captures airborne sound and vibration, cutting noise levels sharply. Placement is straightforward: slabs fit standard cavity sizes, and installation needs only basic tools. After installation, spaces feel quieter and more private—sometimes the difference is dramatic. Because mineral wool cannot burn, melt, or settle with age, it offers reliable long-term performance. For customers like Hans who need to stop corrosion under insulation (CUI) issues, mineral wool also helps by managing moisture and resisting mold. Most acoustic mineral wool today also features certifications for environmental health and safety, making it a responsible choice for modern projects.

Conclusion

Mineral wool, especially rock wool, offers outstanding sound protection, fire safety, and moisture resistance for cavity wall insulation in any environment.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions