Why Should You Choose Rock Wool Insulation for Sale When Upgrading Your Facility?

If you are struggling with rising energy costs or tank maintenance headaches, choosing the right insulation material can solve these problems fast.

Rock wool insulation for sale is the best choice for many industrial projects. It offers proven fire resistance, good thermal performance, and moisture control, making it ideal for tanks, pipes, and factory use.

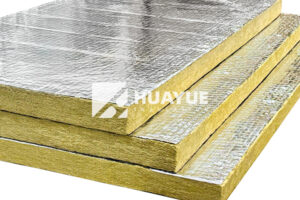

Rock wool insulation product photo

When I first looked into upgrading insulation, I had many options. I discovered that rockwool (also called mineral wool) consistently outperformed other materials for safety. It kept my tanks and pipes dry and resisted heat and fire, which reduced my maintenance costs. Plus, I worried less about safety for my staff.

What Makes Rock wool Insulation Stand Out from Other Materials?

If you’re frustrated by material failures or fire safety worries, rockwool can help you solve these problems quickly and reliably.

Rock wool insulation is non-combustible, resists water, and holds up under tough industrial conditions. It has higher fire safety and better long-term stability than fiberglass or polyurethane insulation.

Rock wool insulation production line

I have compared fiberglass, polyurethane foam, and rockwool side by side. I noticed that fiberglass sometimes absorbs moisture, which leads to corrosion under insulation (CUI). Polyurethane can break down at high temperatures. Rock wool stands out because its fibers are made from volcanic rock, giving it a melting point above 1000°C.

Rock wool does not burn. It creates a barrier that stops fire from spreading, which makes a big difference in places with strict safety codes. It also acts as a sound insulator. In my chemical plant, I once had a fire hazard scare near storage tanks, but rockwool insulation helped contain any damage. This gave me peace of mind.

Here is a simple comparison of properties:

| Property | Rock wool | Fiberglass | Polyurethane Foam |

|---|---|---|---|

| Fire resistance | Excellent | Good | Poor |

| Water resistance | Excellent | Moderate | Poor |

| Load bearing | Good | Fair | Poor |

| Longevity | High | Moderate | Moderate |

| CUI Protection | Excellent | Fair | Poor |

You can see that when I need insulation that stays strong, keeps dry, and meets safety codes, rockwool is my first choice.

How Does Rock wool Insulation Perform in Industrial Tank Applications?

When you worry about tank insulation failing, rockwool can guarantee excellent long-term protection in tough environments.

Rock wool insulation offers high compressive strength and water resistance. It is suitable for use on chemical and cryogenic tanks because it prevents CUI, resists temperature extremes, and lasts for decades.

I have worked with dozens of tank insulation solutions for different projects. Rock wool performs well on both vertical and horizontal tanks. It does not soak up water from leaks, so the steel beneath does not corrode as quickly. When we inspect tanks after years of service, rockwool often looks nearly new.

I use rockwool panels for outer tank walls and pipe insulation. The panels are easy to cut and fit tight. During installation projects, we found that rockwool does not settle or shrink, which prevents gaps that could hurt system efficiency.

Rock wool also improves the energy efficiency of the facility. It keeps heat inside storage tanks and cold inside cryogenic tanks, lowering the cost of heating or cooling. It handles temperature swings from -200°C up to over 700°C. This wide range means I only use one material for multiple applications.

The table below summarizes the best applications of rockwool insulation:

| Application | Benefit |

|---|---|

| Cryogenic tanks | Prevents moisture ingress; stays effective at low temperatures |

| Chemical tanks | Resists chemical corrosion; fire barrier |

| Steam pipelines | Reduces energy loss; prevents burns |

| Storage tanks | Easy installation; long lifespan |

| Acoustic panels | Low noise transmission; keeps facility quiet |

If your goal is to keep tanks safe, cut maintenance, and meet regulations, rockwool will solve these problems reliably.

What Should You Consider When Buying Rock wool Insulation for Sale?

If you want to avoid wasted investments or costly mistakes, paying attention to product specs and supplier reputation is essential.

When buying rockwool insulation for sale, check the density, thickness, and fire rating. Select certified products and work with proven suppliers for consistent quality and global support.

I have been in this business for more than 30 years. I always insist on buying only certified rockwool with ISO and CE approvals. Thicker panels with high density offer better insulation and strength. I check product datasheets, request test samples, and rely on professional suppliers with a strong production capacity.

I choose suppliers that have a record of delivering on time and supporting after-sales service. I also look for flexibility in customization, such as special shapes and coatings.

When evaluating a rockwool supplier, I use these criteria:

| Criteria | Reason |

|---|---|

| Certifications | Proves product safety and quality |

| Production scale | Ensures consistent supply; handles large orders |

| Logistics network | Fast shipping; low risk of delays |

| Custom options | Fit unique tank shapes; add coatings |

| After-sales support | Help with installation and troubleshooting |

I learned early on to avoid unknown brands. The cheapest supplier often costs more in the long run because of hidden failures.

Conclusion

Choosing certified rockwool insulation is the best way to protect your tanks, save money, and meet safety standards for years to come.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

# Is Fiberglass Insulation Dangerous?

Feb 26, 2026

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions