What Is the Right Thickness for Mineral Wool—How Do You Choose?

Sometimes, picking the wrong insulation thickness leads to high energy loss, damaged tanks, or wasted money. Knowing the right thickness for mineral wool saves time, stress, and many headaches.

Mineral wool insulation usually comes in thicknesses between 40mm and 150mm for boards, 50mm to 300mm for pipes, and 50mm to 150mm for rolls. Choosing depends on your project’s thermal, safety, and durability needs.

Many people get stuck picking the correct thickness, not knowing how it affects a facility’s safety, longevity, and energy costs. Let’s look at the options, the dangers of choosing wrong, and some lived experience to guide the process.

What thicknesses does ROCK WOOL come in?

For complex tanks or piping, the insulation’s size needs to fit just right, or you’re left patching mistakes. The huge range of ROCK WOOL thicknesses can be confusing or surprising.

ROCK WOOL is available in many thicknesses: boards from 40mm to 150mm, pipes from 50mm to 300mm, and rolls from 50mm to 150mm. Custom sizes are also possible for project needs.

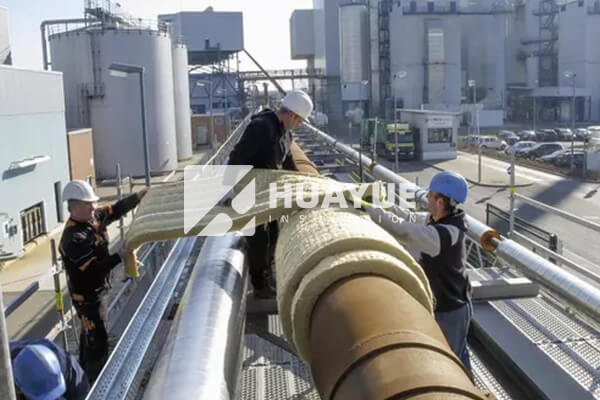

When I work with plant engineers, I always see different tanks and pipes needing specific thicknesses. For example, boards between 40mm to 150mm are great for tank roofs or walls, especially if you need to stop heat loss or protect from fire. ROCK WOOL pipes come thicker—from 50mm to 300mm—since they need to wrap around hot or cold pipes entirely. When teams need rolls for ductwork or large, flexible jobs, the thickness is usually 50mm to 150mm. For projects where the environment is extreme, or regulations need more insulation, I recommend looking into custom thicknesses, because this can save maintenance costs down the road.

Here’s a quick table to break this down:

| Product Form | Thickness Range (mm) | Typical Uses |

|---|---|---|

| Board/Slab | 40 – 150 | Tank tops, walls, flat areas |

| Pipe | 50 – 300 | Pipe insulation (hot/cold) |

| Roll | 50 – 150 | Ducts, flexible surfaces |

When selecting thickness, consider the temperature range, location, and lifespan needed for the insulation. The right choice gives you better results for many years.

Will mice chew through rock wool?

Factories and storage areas often have rodent problems. Many worry that mice will get through the insulation and destroy it. Missing this risk can cause damage and expensive shutdowns.

Mice rarely chew through ROCK WOOL. The dense, fibrous structure is uncomfortable and not nutritious, so mineral wool is usually resistant to rodent attacks.

When I first started working with ROCK WOOL, I was surprised that rodents just ignored it. Mice try to avoid mineral wool because the fibers are sharp and non-edible. That said, if there is food or soft insulation nearby, mice might tunnel through other materials to reach those points—but ROCK WOOL itself isn’t their target.

To help you understand this, here’s a simple breakdown:

| Insulation Type | Rodent Resistance | Comments |

|---|---|---|

| ROCK WOOL | High | Fibers repel gnawing animals |

| Glass wool | Medium | Denser types resist better |

| Foam/plastics | Low | Mice can easily chew through |

So, if rodent control is a top concern, mineral wool (ROCK WOOL) is a safe bet. Still, sealed joints and smart installation block easy entry for mice, stopping problems before they start.

Is mineral wool better than ROCK WOOL?

With many types of mineral insulation, it’s normal to wonder if one is much better than the other. Sometimes, you run into both terms—so is there even a difference?

ROCK WOOL and mineral wool are often used interchangeably. ROCK WOOL usually refers to insulation made specifically from basalt rock, while mineral wool can also include slag wool. Both offer strong thermal, fire, and acoustic insulation.

Most people, myself included, started using “mineral wool” and “ROCK WOOL” as if they meant exactly the same thing. In truth, mineral wool is a family of materials. ROCK WOOL is made from volcanic rock (mainly basalt), while “slag wool” uses industrial waste slag. Both are spun into fibers, then pressed into boards, rolls, or pipes.

Here’s a clear comparison:

| Feature | ROCK WOOL | Mineral Wool (general) |

|---|---|---|

| Raw Materials | Basalt rock | Rock and/or slag |

| Density | High | Medium to high |

| Fire Resistance | Excellent | Excellent |

| Water Absorption | Very low | Varies (usually low) |

In real-world projects, both types work well. They insulate against heat or cold, resist fire, and muffle sound. In my factory projects, I always check certifications and density for each supplier, since these affect long-term quality more than the label on the bag.

How thick should ROCK WOOL be?

This is the biggest question: how do you decide the right thickness? A wrong answer means lost energy or higher long-term risk.

Choose ROCK WOOL thickness by considering the application, local weather, energy goals, and industry rules. For tanks or pipes, thicker insulation (75mm–150mm+) often brings the best combination of heat retention, condensation control, and long system life.

Let me break down what I usually see in big engineering projects. For mild climates or non-critical systems, 50mm–70mm may be enough. Cold climates, cryogenic storage, or chemical tanks may need 100mm, 120mm, or even 150mm of insulation, especially if stopping heat loss and preventing condensation are essential.

Here’s a practical guide:

| Application | Recommended Thickness (mm) |

|---|---|

| Mild climate piping | 50 – 70 |

| Hot process tanks | 75 – 100 |

| Cryogenic/Cold tanks | 120 – 150 or more |

| Energy-saving upgrades | 100 – 150 |

When I work with engineers, we always do a heat loss survey and check industry standards. For example, chemical industry clients, like those in Germany, need 120mm–150mm ROCK WOOL on tank walls for safety code compliance. Always ask for a project-specific recommendation. HUAYUE can customize thickness to any size the job requires, making even difficult specs possible.

Conclusion

Picking the right mineral wool thickness protects your system, saves money, and ensures years of safe operation. Choose based on your real needs and always ask for expert help.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions