What is the Best Rock Wool for Soundproofing?

Many people struggle with noisy environments and want simple, effective soundproofing. If you pick the wrong insulation, then the noise never really goes away.

The best rock wool for soundproofing has fine fibers, is made from basalt, and has a density above 60kg/m³. High-density basalt rock wool is fire-resistant, absorbs sound well, and resists moisture.

Rock wool comes in many types and densities. I have used several brands in my own projects. Some offer only basic noise reduction. Others block sound almost completely. Let’s see what makes some rock wool better than others.

Which Rock wool is best for sound?

Noisy machinery, office chatter, and street traffic can make everyday life stressful. Finding reliable sound-blocking insulation can be difficult.

Fine fiber rock wool made from basalt is best for sound absorption. It traps sound waves and blocks transmission. Basalt-based insulation can reach sound absorption coefficients of 0.85 or higher and fits most wall, ceiling, or tank applications.

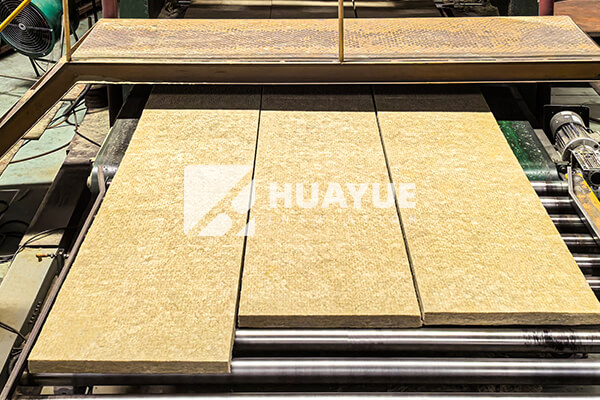

Critical factors include fiber diameter, mineral source, and water resistance. I remember comparing yellow mineral wool to green basalt wool one day. The green basalt wool was softer and easier to handle. It didn’t make me itchy. According to lab tests, fine basalt fibers absorb sound better. Coarse fibers leave gaps and let sound through. HUAYUE’s rock wool uses only high-quality basalt, giving fibers their green tint and smooth texture.

Water resistance also matters. I once had to remove soaked yellow mineral wool after a leak. The sound blocking performance dropped sharply. HUAYUE’s basalt rock wool is treated to repel moisture, keeping its insulation properties even in damp conditions. I have found this helps maintain the long-term soundproofing effect in places like tanks or noisy factories.

Here is a comparison table between mineral wool and basalt rock wool:

| Feature | Mineral Wool (Yellow) | Basalt Rock Wool (Green, HUAYUE) |

|---|---|---|

| Fiber Diameter | Coarse/medium | Fine |

| Fire Resistance | 500°C | 700°C |

| Water Resistance | Low | High |

| Sound Absorption | Average | Excellent |

| Handling Comfort | Itchy | Non-itchy |

| Color | Yellow | Green |

Picking fine fiber basalt rock wool ensures better soundproofing and longer service life.

Is Rock wool good for soundproofing?

Many believe foam or fiberglass is better for sound, but standard insulation cannot block all noise.

Rock wool is very good for soundproofing. It absorbs airborne noise, shields against vibration, and lowers echo in walls, ceilings, and industrial tanks. It outperforms foam and fiberglass in both sound absorption and fire safety.

Soundproofing works best when insulation is thick and dense. I once worked with a factory manager who used fiberglass boards but still complained about machine noise. After we switched to HUAYUE’s basalt-based rock wool panels, the noise dropped noticeably. The insulated room became much quieter and safer.

Rock wool’s fire resistance makes it ideal for places where safety is critical. HUAYUE’s basalt rock wool withstands up to 700°C, while other types often melt at 500°C. For noisy chemical tanks or busy offices, using rock wool means better sound control and safer operation.

Let’s break down soundproofing performance by insulation material:

| Material | Sound Absorption Coefficient | Fire Resistance | Water Resistance |

|---|---|---|---|

| Foam | 0.60 | Low | Medium |

| Fiberglass | 0.70 | Medium | Low |

| Basalt Rock Wool | 0.85 | High (700°C) | High |

By choosing rock wool, you get top soundproofing, fire safety, and water resistance in one product.

What is the best Rock wool density for sound absorption?

Knowing the right density for sound insulation ensures you get the best performance for the money.

For sound absorption, the best rock wool density is 60–100kg/m³. Higher density rock wool absorbs a wider range of sound frequencies and provides structural support for tanks, walls, or ceilings.

When I build soundproof rooms or insulate industrial tanks, I always ask for density certificates. Lower densities are cheaper but do not block low-frequency sounds very well. HUAYUE offers basalt rock wool in densities from 60kg/m³ up to 120kg/m³. If you need to reduce loud machinery noise, pick a higher density—at least 80kg/m³.

Here is a quick breakdown:

| Density (kg/m³) | Sound Absorption | Best Use |

|---|---|---|

| 40–60 | Fair | Office partitions |

| 60–80 | Good | Walls, ceilings |

| 80–100 | Excellent | Industrial tanks |

| 100–120 | Maximum | Special projects |

Fine basalt rock wool at 80–100kg/m³ gives you top value and performance. It handles heavy loads, blocks echoes, and withstands high temperatures in tough environments.

Conclusion

Choose fine-fiber basalt rock wool, density above 60kg/m³, for top soundproofing, fire safety, and moisture resistance across walls, ceilings, and industrial tanks.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions