What are the disadvantages of rock wool insulation?

When selecting building insulation, it is easy to miss hidden drawbacks. Problems later can hurt efficiency and raise costs if you do not evaluate all aspects up front.

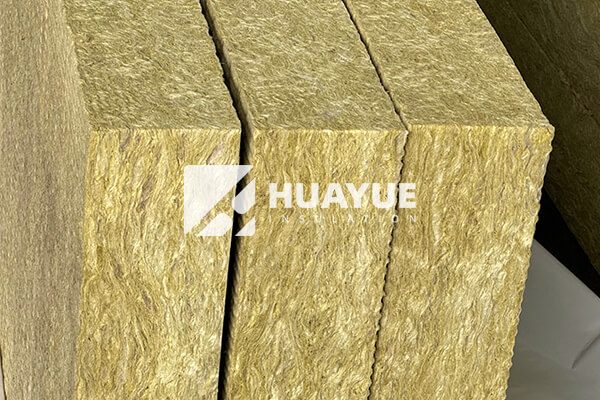

Rock wool insulation is heavier, can irritate skin, costs more than fiberglass, and sometimes absorbs water in poorly sealed applications. Knowing these disadvantages helps builders choose the right material for their project.

Some people believe that rock wool insulation works in all conditions. They expect quick installation and low maintenance. The reality is that every insulation type has unique weaknesses. Avoiding surprises means understanding these issues before starting construction.

Is rock wool insulation harder to install than other types?

A dense, stiff material like rock wool can seem ideal for tight spaces. It holds its shape better than fiberglass batts. However, installers often find rock wool heavier and harder to handle. The added weight slows the work pace and can tire workers quickly.

Rock wool’s stiffness makes it easier to cut precisely, but moving large quantities for wall or roof projects requires more labor. Installers should plan extra time when working with rock wool, especially on high ceilings or tall tanks. The heavier batts may also compress ladders or platforms. Below is a quick comparison:

| Property | Rock Wool | Fiberglass | Foam Insulation |

|---|---|---|---|

| Weight (kg/cubic meter) | 60-80 | 10-30 | 18-45 |

| Ease of Cutting | High | Medium | Low |

| Handling Difficulty | High | Low | Medium |

| Installation Speed | Medium | Fast | Fast |

If your project needs fast installation or has structural limits, extra planning is necessary before you choose rock wool. I advise discussing labor needs with your contractor to avoid last-minute delays.

Does rock wool insulation cause skin irritation or health risks?

Construction materials should be safe both during installation and across their lifespan. I have seen that rock wool fibers, while tough, can irritate exposed skin and sometimes cause breathing discomfort. This occurs most during cutting, handling, or removal.

The mineral fibers in rock wool are non-carcinogenic, but they can lead to rashes and scratchy skin if you touch batts without protective gear. Fiberglass poses similar issues, but some installers report rock wool feels harsher. Eye and respiratory irritation may occur if the workspace is not well ventilated.

Below, I summarize contact precautions typical in the field:

| Exposure Mode | Rock Wool | Fiberglass | Foam Insulation |

|---|---|---|---|

| Skin Irritation Risk | High | Medium | Low |

| Airborne Dust Risk | Medium | High | Low |

| PPE Recommendation | Gloves, Long sleeves, Mask | Gloves, Mask | Gloves, Mask |

| Cleaning After Install | Required | Required | Minimal |

When ordering rock wool products from HUAYUE, I always recommend buyers inform their team and ensure they use the correct protective equipment. This keeps installation safe and comfortable.

Is rock wool insulation more expensive or harder to buy?

Budget is always at the center of major projects. Many buyers notice a higher initial cost per cubic meter when comparing rock wool to fiberglass. The difference comes from both raw material costs and denser batching. Availability can also be an issue. At local stores or smaller distributors, stock levels for rock wool are sometimes insufficient for large jobs.

On big construction projects, delays due to material supply can cause headaches and increase expenses. At HUAYUE, our mature production lines and robust logistics prevent these problems. We ship custom sizes and facings, supporting flexible order volumes and delivering right to your site.

Below is a table outlining cost and sourcing differences:

| Criteria | Rock Wool | Fiberglass | Foam Glass |

|---|---|---|---|

| Average Cost (per m³) | High | Low | High |

| Local Stock Availability | Medium | High | Low |

| Speed of Delivery | High (with supplier support) | High | Medium |

| Custom Order Flexibility | High | Medium | High |

While rock wool has a higher price tag, direct orders from manufacturers like HUAYUE can close the gap. Bulk orders and custom packaging streamline procurement for tight schedules and special needs.

Can rock wool insulation absorb water or lose effectiveness?

Tank insulation must fight against moisture and preserve long-term value. Rock wool resists fire and heat. However, if the covering or vapor barrier is damaged, the dense fibers may absorb water. Trapped moisture leads to reduced insulation value, possible CUI (corrosion under insulation) for tanks, and heavier panels.

This risk is highest outdoors or in chemical plants with frequent liquid exposures. Some buyers choose hydrophobic treated rock wool to reduce the problem. Good installation practices, like overlapping seams and sealing joints, are the first line of defense.

Here is how the absorption factor stacks up:

| Condition | Rock Wool | Fiberglass | Foam Glass |

|---|---|---|---|

| Water Absorption Risk | Medium | High | Low |

| Insulation After Wetting | Drops | Drops | Stable |

| CUI Concern | Medium | High | Low |

| Preventive Measures | Seal Jackets, Use Hydrophobic Batts | Seal, Replace Wet | Use Non-absorbing Material |

When managing a chemical tank project, I advise always checking for moisture inhibitors and confirming proper sealing. At HUAYUE, we offer customized solutions including hydrophobic rock wool and expert installation support to keep your system protected.

Conclusion

Rock wool insulation offers strong thermal performance, but disadvantages include higher cost, heavier weight, health precautions, and water absorption risk. Careful planning solves most problems.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions