Vinyl Fiberglass Insulation: Is It the Right Choice for Modern Metal Buildings?

When installing insulation for metal buildings, we always want long-lasting performance and value, but there are many options—how can we decide what’s truly best?

Vinyl fiberglass insulation combines the thermal performance of fiberglass with the protective barrier of vinyl, making it a top choice for metal buildings that need both energy savings and moisture control.

When I first started evaluating insulation for large industrial projects, I quickly realized how important the right material can be. There are so many types—each with its pros and cons—so it is hard to navigate the options. Keep reading to see why vinyl-faced fiberglass insulation is often the preferred solution, especially for demanding metal building projects.

Vinyl Faced Metal Building Fiberglass Insulation: What Makes It Different?

Metal buildings face unique environmental challenges, but the right insulation can solve several issues at once.

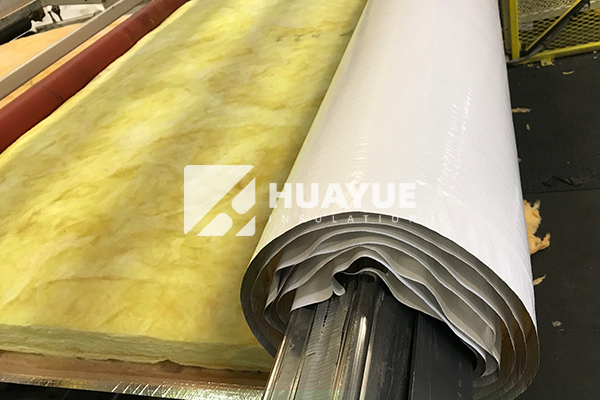

Vinyl faced fiberglass insulation is designed for metal buildings because the vinyl facing adds a strong vapor barrier and a cleaner finish. This insulation helps stop heat loss in winter and keeps heat out in summer. The vinyl layer makes the fiberglass safer to handle and creates a neat, washable interior look.

When I worked with plant engineers on retrofitting older warehouses, we often faced complaints about sweating walls, drafts, and rising energy bills. Once we switched to vinyl-faced fiberglass, those problems dropped off. The vinyl facer locks out moisture, trapping it before it can reach the fiberglass core. This helps cut condensation and mold issues, protects the metal from corrosion, and makes the inside of the building look clean and finished. Below is a simple table comparing features:

| Feature | Plain Fiberglass | Vinyl-Faced Fiberglass | Remarks |

|---|---|---|---|

| Thermal Resistance | High | High | Both provide good R-value |

| Moisture Protection | Low | Very High | Vinyl is a vapor barrier |

| Handling Safety | Medium | High | Vinyl prevents skin itch |

| Finish Appearance | Poor | Clean/White | Vinyl gives a tidy look |

| Mold Risk | Higher | Much Lower | Keeps insulation dry |

Each line of this table comes from problems I have seen on job sites. Vinyl-faced fiberglass just keeps things simpler, cleaner, and longer-lasting for metal buildings.

What are the Advantages and Disadvantages of Fiberglass Insulation?

Everyone says fiberglass insulation is popular, but is it always the best choice?

Fiberglass insulation is favored because it offers a high R-value for the price. It is easy to install, does not attract pests, and is naturally non-combustible. However, it can lose performance if it gets wet, can irritate skin during installation, and does not block air leaks unless properly sealed.

I have seen both sides of fiberglass use in real projects. On the plus side, it is affordable, flexible, and easy to fit snugly in wall and roof cavities. Contractors love how fast it can be installed. The downside is, without a proper vapor barrier (like vinyl), plain fiberglass can soak up moisture, sag over time, and lose its insulation value. If not handled with care, the fibers may cause itching and discomfort to workers. Cost-wise, fiberglass is almost always less expensive than closed-cell foams or mineral wool. Below is a breakdown showing where fiberglass shines and where it falls short:

| Advantages | Disadvantages |

|---|---|

| Good R-value per dollar | Needs vapor barrier in humid areas |

| Fire-resistant | Can irritate skin/lungs |

| Easy to cut and install | Loses R-value if wet |

| Does not settle over time | Can’t seal against air leakage |

| No food source for pests/mold | Requires protective gear to install |

In short, fiberglass works best with some enhancements—like vinyl facing for moisture protection—especially in metal structures where moisture and air leaks can be bigger problems.

Why White Vinyl Faced Fiberglass Insulation Is Preferred?

Contractors and facility managers keep choosing white vinyl faced fiberglass—why is this color and facer combination so popular?

White vinyl faced fiberglass insulation is favored for its clean look, strong vapor barrier, and added light reflection inside buildings. The white surface also helps with visibility, creates a finished appearance, and is easier to keep clean than exposed fiberglass.

I remember touring a chemical storage facility where tanks lined the walls and overhead piping made working spaces shadowy. After switching to white vinyl faced fiberglass, visibility improved, and the maintenance team said cleanup was easier. The white face reflects more light, reduces shadows, and makes spaces feel brighter. Beyond looks, the vinyl provides critical moisture control, preventing condensation from reaching the metal panels. This cuts down rust and corrosion, which is a must for places with sensitive equipment or chemicals. Finally, the facer holds fibers in place, stopping dust and reducing inhalation risks for staff. Here’s why white vinyl has the edge:

| Benefit | How It Helps Metal Buildings |

|---|---|

| Brighter interior | More light, better working space |

| Tough vapor barrier | Stops moisture & condensation |

| Better hygiene | No exposed fibers, easy to clean |

| Professional appearance | Good for office/warehouse combos |

| Stays neat over time | Easy to patch, resists stains |

Every time I compare options with engineers or project managers, this winning group of features usually puts white vinyl faced insulation at the top of the list for new and retrofit jobs.

Wholesale Fiberglass Insulation Products From HUAYUE

Need reliable bulk insulation products for your next project? HUAYUE offers a full service approach from factory to job site.

At HUAYUE, I help you choose from a wide range of fiberglass insulation products—including flexible batts and rolls with different vinyl facers—so your order matches your exact building needs. Our factory-direct supply means better pricing, steady quality, and quick delivery through top ports.

I have walked many plant floors and seen customers frustrated by inconsistent quality or delayed shipments from overseas. With HUAYUE, you get certified products with ISO and CE approvals. Our 15 advanced production lines keep orders moving fast, and our global shipping network reaches Europe, North America, South Asia, and beyond. I am proud that our materials help keep critical sites energy-efficient and safe. Below is a selection of what we offer and deliver:

| Product Type | Facing Options | Application | Key Features |

|---|---|---|---|

| Fiberglass Blanket | White/Black Vinyl | Metal wall & roof | Strong vapor barrier, long lifespan |

| Fiberglass Board | Foil, Vinyl | Pipe/duct insulation | Rigid, easy to cut, good protection |

| Custom Size Rolls | Vinyl/Film | Warehouses/facilities | Fast install, better coverage |

Since 1998, HUAYUE has built a name for quality and service in insulation. This lets you build better, safer facilities—no matter the climate, load, or design.

Conclusion

Vinyl faced fiberglass insulation offers top protection, better aesthetics, and strong value for metal buildings. With the right supplier, you get dependable quality and better results for every job.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions