Rockwool Pipe Insulation: Is It the Best Choice for Your Facility?

If you manage critical tank or piping systems, finding insulation that lasts and keeps things safe can be stressful.

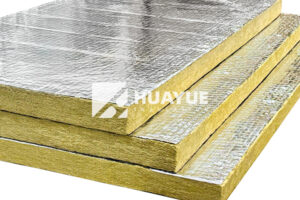

Rock wool pipe insulation can be placed around pipes to improve their thermal efficiency, prevent condensation, and resist fire. It is especially effective for high-temperature applications and facilities that require robust safety measures.

When I started looking into options for long-term insulation, rock wool stood out. Many engineers know it for its fire resistance and sound absorption. But I wanted to dig deeper and see if this material truly solved problems in large facilities. There are a lot of factors to consider, so let’s look at the details together.

Can you put ROCK WOOL insulation around pipes?

Sometimes it is hard to find an insulation that fits pipes well and lasts through harsh conditions.

Yes, you can put Rock wool insulation around pipes. It typically comes in pre-formed pipe sections or flexible rolls, making installation straightforward and ensuring a snug fit for reliable thermal and fire protection.

Installing rock wool pipe insulation feels simple. The pre-formed sections are cut to fit standard pipe diameters, and the flexible rolls are good for odd shapes or large piping bundles. Most engineers start by wrapping the pipe sections and securing them with metal bands or wire. The insulation resists heat and won’t melt or smoke in a fire. The density helps reduce heat loss and blocks sound from flowing through pipe walls.

Here is a quick chart about the practical features of Rock wool insulation for pipes:

| Key Feature | Description |

|---|---|

| Fire Resistance | Won’t burn, smoke, or drip in a fire |

| Water Resistance | Repels water while allowing vapor escape |

| Temperature Rating | Safe for uses up to 700°C |

| Sound Absorption | Reduces noise from pipes and pumps |

| Simple Installation | Pre-formed or roll format; easy to fit |

Proper installation is important. If rock wool sections are not tightly joined, heat can escape. I make sure every joint lines up and consider a vapor barrier for cold pipes. Most maintenance crews find replacement easy. Rock wool rarely needs patching and won’t sag over time. In factories, this lets me focus less on future repairs.

What are the negatives of ROCK WOOL insulation?

Sometimes it feels like nothing is perfect, even with the safest and strongest material.

Rock wool insulation has drawbacks: it can be more expensive than other materials, may cause skin irritation during installation, and needs careful protection from prolonged water exposure to prevent degradation.

One thing to know is rock wool fibers can cause skin or lung irritation. I always wear gloves and a mask when handling it. That solves most comfort problems. Rock wool is not cheap. If your facility is watching costs closely, fiberglass or foam might seem more attractive. I weigh the lifetime savings from reduced fire risk and fewer repairs against the bigger upfront cost.

Water resistance is good for surface splashes, but roc kwool will soak up water if left wet for a long time. If tanks or pipes sweat, it helps to add a vapor barrier. Metal cladding works well to shield from leaks or weather. When using rock wool outdoors, moisture protection must be part of the plan. A small investment in proper installation goes a long way to maintain performance and avoid high maintenance bills.

| Drawback | Impact | Solutions |

|---|---|---|

| Initial Cost | More expensive than basic alternatives | Assess long-term savings |

| Skin/Lung Irritation | May cause discomfort during installation | Use PPE |

| Prolonged Water Exposure | Loses effectiveness if soaked through | Add vapor barrier, cladding |

| Weight | Heavier than foam or fiberglass | Factor into pipe support |

I always work with the safety team to address these negatives upfront. Training and planning help my crew avoid the pitfalls. The result is a dependable insulation that supports plant safety and long-term energy efficiency.

What is ROCK WOOL insulation used for?

People often ask me what industries use rock wool, or if it’s only for specialty applications.

Rock wool insulation is used to protect pipes, tanks, ducts, and industrial equipment from heat loss and fire. It is favored in chemical plants, energy facilities, and buildings needing high safety and noise control.

Rock wool finds its way into many places. Power stations use it on steam lines because it will not burn. Chemical plants, like the one I am responsible for, use rock wool around reaction vessels and cryogenic tanks. The fire rating and sound deadening mean it is also popular on building HVAC ducts and even inside walls to block noise between rooms.

Table of common applications:

| Application | Reason for Use | Example |

|---|---|---|

| Pipe Insulation | Prevents heat/cold loss, resists fire | Steam/chemical piping |

| Tank Cladding | Controls condensation, protects metal | Cryogenic, hot water tanks |

| Ducts | Reduces noise, blocks heat transfer | HVAC ductwork |

| Equipment Covers | Improves safety, energy efficiency | Boilers, turbines |

| Building Walls | Stops noise, enhances fire safe construction | Residential or office walls |

Long-term stability and resistance to compression are key reasons why engineers—myself included—use rock wool in high-demand spots. Its mineral composition means it cannot rot or rust. No pests or mold damage it. When designing a new facility, I consider rock wool if the system must stay safe, efficient, and strong for decades.

What is the thermal conductivity of Rock wool pipe insulation?

Thermal performance is usually the top concern for me and the maintenance team.

Rock wool pipe insulation has thermal conductivity between 0.032 and 0.040 W/mK. This low rate means rock wool efficiently stops heat from leaving pipes, conserving energy and keeping the process stable.

The thermal conductivity number tells how fast heat moves through the material. Lower numbers are better. With rock wool’s range, it stacks up well against fiberglass or foam. For example, the typical glass wool sits around 0.040 W/mK, while polyurethane foam can reach as low as 0.025 W/mK. Though foam has slightly better insulation, it lags behind rock wool in fire resistance and long-term stability.

Here is a comparison:

| Material | Thermal Conductivity (W/mK) | Fire Resistance | Water Resistance |

|---|---|---|---|

| Rock wool | 0.032 – 0.040 | Excellent | Good |

| Glass wool | 0.040 – 0.045 | Good | Moderate |

| Polyurethane foam | 0.025 – 0.030 | Poor | Excellent |

| Rubber foam | 0.034 – 0.040 | Poor | Excellent |

The low thermal conductivity of rock wool means less heat escapes from hot water or steam pipes in factories. This saves energy and makes process temperatures easier to control. I rely on this, especially where precise conditions help keep chemical reactions stable or prevent freezing in winter.

Conclusion

Rock wool pipe insulation offers durable fire protection, strong thermal performance, and easy installation for industrial pipes, with a few drawbacks like cost and moisture care.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

# Is Fiberglass Insulation Dangerous?

Feb 26, 2026

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions