Rock Wool: Where to Buy for the Best Results?

Many businesses struggle to find reliable sources for rock wool, costing time and risking quality—don’t let frustration and uncertainty slow your project.

You can buy high-quality rock wool from established manufacturers with solid export history, broad product selection, and proven international partnerships, ensuring consistent performance, availability, and the best prices for your needs.

Accessing trustworthy rock wool suppliers makes a real difference in construction and industrial projects. You might wonder where you should start your search and how to know if a supplier matches your expectations. I have spent nearly three decades working in insulation manufacturing and export. Good rock wool is critical in plant construction, tank insulation, and energy savings. I have seen how the right supplier can make projects simple. The wrong source brings stress and costly repairs. Let me help you sort through the main questions.

Where to order Rock wool from?

Delays, low-quality products, and missing certifications can derail a project—I have faced these problems and know they lead to wasted money and headaches.

Order rock wool direct from reputable manufacturers or their local authorized distributors who show certifications, track records, and offer technical support with flexible delivery options.

When you want to order rock wool, start by looking for companies with experience in manufacturing, exporting, and supplying a range of rock wool products. Ask if they own their production lines and industrial parks. I know from experience that companies with modern facilities and real manufacturing strength can promise both quality control and stable supply.

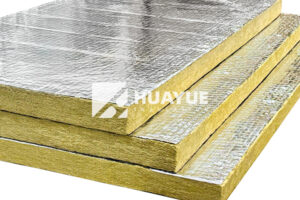

Check for ISO, CE, and SGS certifications. Ask if the supplier has dealt with international shipping and customs regulations. This is important if your site is outside the supplier’s home region. Manufacturers like us, with large industrial parks, automated production lines, and years of export experience, ensure consistent quality. We offer different types of rock wool, such as pipes, boards, and rolls, with options for various facings. That flexibility lets you find exactly what you need for each project stage.

A strong supplier also offers technical support. They answer installation questions and help pick the right specifications for your climate, fire protection, or load needs. Below is a simple table to compare supplier types:

| Supplier Type | Pros | Cons |

|---|---|---|

| Direct Manufacturer | Best price, quality control | Higher minimum order size |

| Authorized Distributor | Local stock, support | Slightly higher pricing |

| Online Retailer | Fast for small orders | Limited product range, risk |

| Unverified Reseller | Lowest price sometimes | Quality and spec uncertainty |

Getting the best value means confirming both the product specs and the service are aligned with what your project really needs.

What is another name for ROCK WOOL?

Confusion happens when people use different terms for the same thing, leading to ordering errors that cost time and money.

Rock wool is also known as mineral wool, stone wool, or slag wool, depending on its main raw materials and the region.

I often find buyers get confused because “rock wool” can appear under different names on specifications or catalogs. In international projects, these terms sometimes mean the same broad class of insulation. The term “mineral wool” is the umbrella—it covers both rock wool (made from basalt or other rock) and slag wool (made from metallurgical slag). Stone wool often refers to rock wool made mostly from natural rock.

Let’s look at a quick breakdown:

| Name | Main Raw Material | Common Use |

|---|---|---|

| Rock Wool | Basalt/Volcanic Rock | Construction/Industrial |

| Stone Wool | Basalt/Natural Stone | Construction |

| Mineral Wool | Rock or Slag | General/Construction |

| Slag Wool | Metallurgical Slag | Specialized/Industrial |

So, when ordering, ask for the technical data sheet or certificates to be sure the material fits your fire, thermal, and mechanical needs. In my projects, this step avoided mix-ups many times.

Is there a cheaper version of ROCK WOOL?

Budgets drive most projects—and paying too much for insulation eats into profit margins or forces compromises elsewhere.

The most budget-friendly rock wool is usually standard-density, unfaced rolls or slabs made by leading manufacturers who use mass production to lower costs.

Looking for ways to save does not mean you give up quality. In our experience, purchasing directly from established producers who run several automated production lines can get you very competitive pricing, especially when you have bigger orders. Lower-density or basic unfaced products are usually the cheapest rock wool forms. Adding specialty facings, custom shapes, or small batch runs increases costs.

It helps to ask the supplier for their best price per ton on full-container or truckload orders. Insider tip: For big export or construction jobs, you can often negotiate better prices or get free samples if you provide steady or repeat business.

Compare this in a table:

| Rock Wool Type | Cost Level | Best For |

|---|---|---|

| Standard Unfaced Slab | Low | Walls, ceilings, roofs |

| Pipe Insulation | Medium | Tank, pipe, process lines |

| High-Density Board | High | Floor, load-bearing areas |

| With Foil Facing | Higher | Extra moisture/fire needs |

Knowing the use case helps you pick the rock wool that really meets your project’s needs while keeping costs under control.

Will mice chew through rock wool?

Rodents can destroy insulation and cause costly system failures. I have seen projects where hidden damage led to leaks or fire risks.

Mice usually do not chew through rock wool because it is dense, non-organic, and unappealing for nesting or eating.

I talk to plant engineers and facility managers in Europe and Asia who worry about pest resistance. Rock wool is mostly made from minerals, so mice find it uncomfortable and unattractive. It does not provide food or soft nesting spots. In almost thirty years, I have rarely seen rodent activity in properly installed rock wool systems—but gaps or exposed edges can attract problems.

For extra peace of mind, make sure your insulation is tightly fitted, with no voids for pests to enter. Use metal cladding or finishes in sensitive areas. Some projects even specify pest-resistant facings as a backup layer.

Here is a summary table:

| Material | Rodent Chew Risk | Common Action |

|---|---|---|

| Rock Wool | Very Low | No extra treatment |

| Glass Wool | Low | Tightly seal joints |

| Foam Board | High | Use with barriers |

| Mineral Wool | Very Low | As with rock wool |

Adding these installation steps helps stop most pest problems before they start.

Can you touch rockwool with bare hands?

Direct contact with rock wool can sometimes irritate the skin—itchiness and mild redness are not uncommon.

It is usually safe to touch rock wool with bare hands for short periods, but gloves and long sleeves help prevent skin irritation from loose fibers.

Most modern rock wool products are designed with less fiber release than decades ago. When I work on jobsites, I still recommend anyone handling rock wool wears basic work gloves and covers exposed arms. While the loose fibers may cause irritation for some people, the effect goes away quickly and does not cause lasting harm.

Do not rub your eyes after touching rock wool, and wash your hands with soap when finished. If you are working in limited spaces or handling many pieces, a dust mask and goggles add extra protection. Good jobsite practice keeps work conditions comfortable.

| Handling Situation | PPE Needed | Risk Level |

|---|---|---|

| Brief contact, small projects | Gloves advised | Low |

| Prolonged or overhead work | Gloves, sleeves, mask | Medium |

| Cutting or shaping rock wool | Gloves, mask, goggles | Higher |

Learning proper handling habits early keeps your team and yourself comfortable on every job.

Conclusion

Buying the right rock wool means choosing suppliers with real strength, picking the right specs, and knowing best practice for safe, effective, and cost-efficient results.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

# Is Fiberglass Insulation Dangerous?

Feb 26, 2026

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions