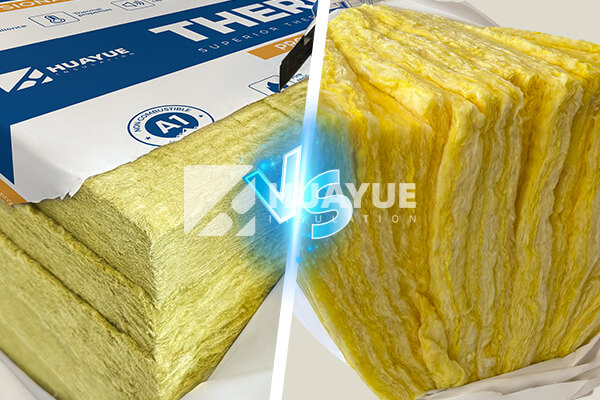

Rock Wool Insulation vs Fiberglass Insulation: Which Is Better for Your Next Project?

Insulation is critical to building performance, but choosing between rock wool and fiberglass can feel overwhelming when every project seems to demand something different.

When comparing rock wool and fiberglass insulation, consider their differences in fire resistance, temperature tolerance, moisture resistance, and cost. Rock wool typically offers higher fire resistance and better thermal performance, while fiberglass tends to be more affordable and widely used for residential applications.

Finding the right insulation often means weighing each material’s traits against your project’s specific demands. I’ve had to make this choice myself – balancing long-term safety, thermal efficiency, and total costs. Knowing these critical differences helps me feel confident in every recommendation I give. Next, I’ll break down the major comparison points one by one.

What Are the Main Differences Between Rock Wool and Fiberglass Insulation?

Choosing insulation is more than just comparing two types—it’s about solving real problems like fire risk or high energy costs.

The main differences are in how they’re made, their heat resistance, density, and fire performance. Rock wool is spun from volcanic rock, excels at high temperatures, and naturally resists fire. Fiberglass, made from glass, is lighter, easier to install, but less robust in extreme conditions.

Production, Performance, Safety: Breaking Down the Key Attributes

When I walk a job site, the questions that come up most are about durability, safety, and ease of use. Here’s how I lay out the side-by-side differences for a client:

| Feature | HUAYUE Rock Wool Insulation | HUAYUE Fiberglass Insulation |

|---|---|---|

| Base Material | Volcanic rock | Recycled glass |

| Maximum Temperature | Up to 649°C | Below 350°C |

| R-Value (per inch) | Higher | Moderate |

| Fire Resistance | Naturally non-combustible | Fire-resistant but melts sooner |

| Density | High (heavier, denser) | Lower (lighter) |

| Moisture Resistance | Excellent, resists mold/mildew | Good, but absorbs slightly more |

| Typical Application | Industrial, high-heat settings | Residential, light commercial |

| Cost | Higher | Lower |

| Sustainability | Energy-intensive | Made from recycled content |

Rock wool’s higher density means it stays put in mechanical rooms or around industrial tanks—especially where vibration is common. I saw this myself at a busy chemical plant, where rock wool stayed intact through years of intense heat and maintenance. On the other side, fiberglass is flexible, lighter, and quick to install, making it ideal for covering dozens of residential attics in a short week.

Certifications matter too. Both HUAYUE rock wool and fiberglass products carry ISO and CE marks, but for some clients, only the higher fire rating of rock wool meets building codes for critical safety zones.

Where Should I Use Each Insulation Type?

When stakes are high—like protecting against fire or chemical spills—the choice of insulation can mean safety or costly downtime.

Use rock wool insulation for industrial tanks, oil and gas facilities, and power plants where temperatures swing high and fire risk must be minimized. Use fiberglass insulation for wall cavities, attic spaces, and light commercial projects where budget and rapid installation are primary concerns.

Application Scenarios: Matching the Material to the Job

I often walk through a new facility with a plant manager like Hans Müller, weighing the long-term impact of every material. Here’s how I usually break it down:

Ideal Scenarios for HUAYUE Rock Wool Insulation

- Cryogenic tanks, chemical storage, and areas with extreme temperature swings

- Power plant steam lines, turbines, and hot process equipment

- Locations subject to strict fire safety regulations

Ideal Scenarios for HUAYUE Fiberglass Insulation

- Commercial office walls, drop ceilings, and retail buildings

- Residential attics, wall cavities, HVAC ducts

- Spaces where ease of handling, speed of installation, and cost dictate choices

| Project Type | Recommended Insulation | Main Benefit |

|---|---|---|

| Industrial Tank | HUAYUE Rock Wool | Fire, heat, and moisture resistance |

| Residential Attic | HUAYUE Fiberglass | Affordability, installation speed |

| Large Utility Building | Either (case-by-case) | Balanced needs |

| High Fire Safety Areas | HUAYUE Rock Wool | Superior fire resistance |

Using the right insulation gives peace of mind. I remember the look on Hans Müller’s face when the right rock wool solution meant one less worry about corrosion or fire code violations at his chemical plant.

Conclusion

Choosing between HUAYUE rock wool and fiberglass comes down to matching the insulation’s strengths to your project’s priorities—whether heat, fire, moisture, or cost.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions