Looking for Reliable Rock Wool Suppliers?

Rock wool insulation is a top solution for energy efficiency, but picking the right supplier can be tricky. You need high thermal performance and consistency every time.

If you want the best rock wool, focus on finding suppliers who offer not only competitive prices, but also strict quality standards, varied customization, and technical expertise to meet your project requirements—especially for construction or heavy industry.

When I first started sourcing rock wool, I quickly learned not all suppliers are the same. It’s not just about the lowest price. The type of raw material, custom support, and product quality make a big difference. Let me break down the key points you should watch for when searching for trustworthy rock wool suppliers.

Who manufactures Rock wool?

Rock wool is made by specialized manufacturers with advanced production lines, using natural stone like basalt to create fibers for insulation.

The leading rock wool manufacturers source high-grade basalt or other volcanic stone, then process it at high temperatures to form fine fibers. Top suppliers usually provide technical documentation and custom packaging to match project needs.

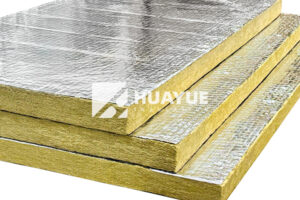

When you look at the global market for rock wool, you will see several big players. There are giants from Europe and smaller regional suppliers, along with strong manufacturers in Asia. For example, our company—HUAYUE—uses basalt as the main raw material, rather than generic slag or recycled rock. This matters. Basalt-based rock wool has a subtle green color compared to the more yellow tone seen in products made mainly from slag wool or mineral waste.

| Let’s compare materials and quality: | Manufacturer Type | Main Raw Material | Color | Fiber Diameter | Max Operating Temp | Water Resistance | Custom Packaging | Technical Docs |

|---|---|---|---|---|---|---|---|---|

| HUAYUE (China) | Basalt | Greenish | Very fine | ~700℃ | Yes | Yes | Rich | |

| Generic Mineral Wool Supplier | Slag/Mineral waste | Yellowish | Coarser | ~500℃ | Sometimes | Some | Basic | |

| European Brand | Basalt/Blend | Varies | Fine | ~600-650℃ | Yes | Yes | Good |

Choosing a supplier like HUAYUE means you get a consistent basalt product, which often feels less “itchy” on the skin, gives better insulation, is more fire-resistant, and is waterproof. Always check the certifications—ISO, CE, SGS—and look for suppliers who support both standard and custom-sized orders.

Are mineral wool and Rock wool the same?

Mineral wool and rock wool are closely related, but they are not exactly the same. Rock wool is made mainly from basalt, while mineral wool can include slag wool from industrial waste.

Mineral wool covers a broader group of insulation materials, which includes both rock wool (from natural stone) and slag wool (from steel or metal industry waste). When you choose rock wool, you pick a product with higher natural stone content, usually giving you better durability, higher fire resistance, and a more consistent structure.

There is a big difference in source materials and resulting properties. I have seen project managers confuse the two when quoting for tank insulation or building envelopes. The major thing to watch is fiber quality and fire performance. For example, HUAYUE rock wool uses pure basalt, which is why it performs up to 700℃, making it ideal for high-heat or fire safety-focused applications. Slag-based mineral wool usually stays around 500℃ and, in my experience, can absorb more water if not properly treated.

Here’s how to tell them apart:

- Ask for the technical datasheet or request a product sample.

- Check the color: basalt rock wool will have that greenish look; slag-based products look more yellow.

- Feel the fiber: finer basalt fibers are less itchy and more uniform.

- Look at the certifications and see if the supplier references the product as ‘rock wool’ or only ‘mineral wool’—Suppliers with strong documentation, like HUAYUE, can always clarify these points for your engineers.

Wholesale Mineral Wool Batt Insulation Supplier

A good wholesale mineral wool batt insulation supplier offers bulk pricing, custom orders, technical support, and reliable logistics—so you never run into supply chain delays.

Wholesale suppliers like HUAYUE don’t just sell large volumes. They give you value by supporting tailored sizes, dedicated account service, and supplying all the technical documents you might need to pass local regulations or project audits. If you run large-scale work—say, a new tank farm or a building retrofitting project—having a supplier that can deliver custom-length or density batts is as important as the price.

Let’s look at how a leading supplier works:

- You can order batts cut to your exact thickness or shape, packed under your own brand (OEM/ODM).

- You get clear, thorough documentation for each batch, often with test reports (fire resistance, conductivity, water repellency).

- Logistics support is critical: located close to major export ports, HUAYUE can ship orders fast anywhere in Europe, North America, or South Asia—with the global experience to clear customs without problems.

- Mass production capacity—like HUAYUE’s 45,000 tons per year—means you rarely have to wait.

- Certification like ISO, CE, and SGS proves you are buying up-to-standard and safe insulation.

If you ever deal with project tendering, you know how vital it is to provide detailed spec sheets and quality guarantees. A wholesale partner who tracks every detail for you gives you leverage, whether you care about maintenance, long-term durability, or cost control.

Conclusion

Choosing the right rock wool supplier comes down to material quality, reliable supply, and technical support. Look for basalt-based products, strong documentation, and a supplier you can trust to deliver every time.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

# Is Fiberglass Insulation Dangerous?

Feb 26, 2026

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions