Is mineral wool insulation the key to better soundproofing?

When unwanted noise turns comfort into chaos, finding a reliable soundproofing solution becomes urgent.

Mineral wool is a great option for soundproofing because its dense, fibrous structure absorbs sound effectively, reduces noise transmission, and improves room acoustics.

Many people find themselves dealing with noisy neighbors, loud traffic or echo-filled rooms. Like them, I once struggled with poor soundproofing in my home office. Soundproofing is a concern for both homes and industrial spaces. When considering insulation, mineral wool often comes up as the top choice. Let’s dive deeper to see why, and what you should know if you’re considering mineral wool insulation as your answer for managing sound and quiet.

Is mineral wool good for soundproofing?

Noise creeps into quiet spaces and ruins focus or sleep. Soundproofing is important for peace and productivity.

Mineral wool is good for soundproofing because its dense, open structure traps airborne sounds. It also helps block impact noise between walls and floors.

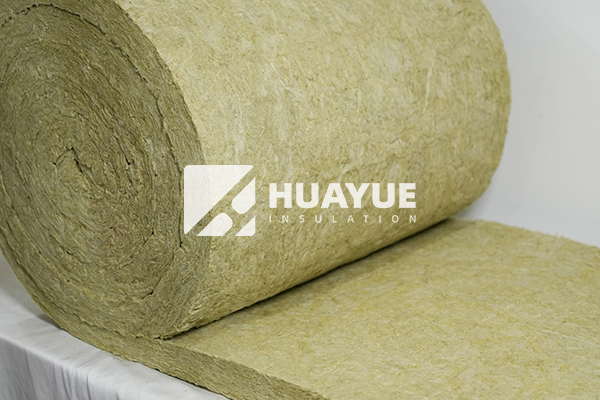

Mineral wool insulation, also known as rock wool, is made by spinning molten rock or slag into fibers. This structure creates millions of tiny air pockets. These pockets capture sound waves and slow them down. The density of mineral wool means it does not just block high-frequency sounds, but also those with lower energy, like voices or heavier footsteps. Building codes in many countries use mineral wool for its fire safety, water resistance, and its proven ability to reduce noise levels. When I built a recording room, mineral wool panels helped cut down street noise and kept echoes from disrupting my work. Most people find these panels easy to install. You can fit them between standard wall studs or ceiling joists. Below is a simple comparison table to illustrate how mineral wool stands out against other common soundproofing materials.

| Material | Sound Absorption | Fire Resistance | Water Resistance | Typical Use |

|---|---|---|---|---|

| Mineral Wool | Excellent | High | Moderate | Walls, ceilings |

| Fiberglass | Good | Moderate | Moderate | Walls, HVAC ducts |

| Foam Panels | Moderate | Low | Low | Studios, offices |

Which insulation is best for soundproofing?

Everyone wants the quietest environment possible, especially when working or relaxing. The right insulation makes all the difference.

Mineral wool stands out among insulation options for soundproofing because it absorbs, traps, and dissipates sound better than most other materials.

Choosing insulation for soundproofing depends on the noise challenges you face. For airborne noise, mineral wool is an excellent solution. It outperforms fiberglass in absorption at most frequencies. Foam acoustic panels do fine in studios or for echo management, but they aren’t durable or fire safe for walls or ceilings. In heavy-duty environments, like machinery rooms or multi-family housing, mineral wool’s higher density blocks sound and resists mold. I’ve compared materials for the walls of apartment buildings. Mineral wool consistently delivers quieter bedrooms and reduces complaints. You can easily install it behind drywall or in double-stud walls for the best performance. Below is a table summarizing how different insulation types measure up:

| Insulation Type | Sound Absorption Rating | Ease of Installation | Safety Rating | Best use |

|---|---|---|---|---|

| Mineral Wool | Very High | Easy | Fire Safe | Between wall studs, ceilings |

| Fiberglass | High | Easy | Moderate | General home use |

| Cellulose | Moderate | Easy | Moderate | Attics, retrofit |

Is 2 inch mineral wool an effective sound absorber?

Thin insulation often gets overlooked, but can it still silence a noisy environment? Many wonder if just 2 inches is enough.

Yes, 2-inch mineral wool is an effective sound absorber, especially for mid- and high-frequency noise in walls and ceilings.

Mineral wool’s performance is directly related to its thickness and density. Two inches works well for home studios, offices or apartments with typical noise levels. For lower frequency sounds — such as deep bass or heavy footsteps — thicker insulation delivers better results. But in most homes or commercial applications, 2-inch panels provide significant improvements. I’ve measured before-and-after room sounds; adding 2-inch mineral wool dropped the sound levels by several decibels. When you install these panels in wall cavities or drop ceilings, you get acoustic comfort without taking up valuable space. Below is a quick breakdown comparing typical sound absorption values for mineral wool of different thicknesses.

| Thickness | Mid/High Frequency Absorption | Low Frequency Absorption |

|---|---|---|

| 2 inch (50 mm) | Excellent | Moderate |

| 4 inch (100 mm) | Excellent | Good |

| 6+ inch (150 mm) | Excellent | Very Good |

How effective is rock wool for soundproofing?

Rock wool promises a quieter life; but does it work for complex, industrial or high traffic environments?

Rock wool is highly effective for soundproofing because it reduces airborne, impact, and vibration noise. It also resists moisture and fire.

Rock wool is often chosen for factories, chemical plants, and large commercial buildings. Hans Müller, chief plant engineer in Germany, relies on rock wool to keep tank systems quiet and safe from vibration noise. In addition to stopping sound, rock wool resists corrosion, lasts for years, and doesn’t burn when exposed to open flames. That’s why it’s used in industrial insulation upgrades and replacements. I’ve seen this material used in machinery rooms, stairwells, and even under industrial tanks where vibration is a problem. Below is a table that explains how rock wool performs versus common alternatives for industrial sound control.

| Material | Airborne Noise Reduction | Impact Noise Reduction | Vibration Absorption | Fire Resistance | Lifespan |

|---|---|---|---|---|---|

| Rock Wool | High | Moderate | Excellent | High | Very Long |

| Fiberglass | Moderate | Low | Moderate | Moderate | Long |

| Polyurethane | Low | Low | Low | Low | Moderate |

What are the disadvantages of mineral wool?

No product is perfect. It’s important to know the drawbacks before you buy insulation in bulk.

Disadvantages of mineral wool include higher cost, potential skin irritation, and difficulty cutting without proper tools.

Mineral wool can cost more than fiberglass or foam alternatives. When I first handled mineral wool, I noticed it sometimes caused itching — gloves and masks are needed for long installs. Cutting it cleanly requires sharp knives. Disposal must be done safely to avoid loose fibers. Mineral wool is heavier, so some installers find it harder to work with overhead or in tight corners. While its fire and water resistance make it reliable, its weight and texture demand careful planning. If budget is limited, fiberglass might be better, though soundproofing and safety might suffer. Below is a simple list of the main disadvantages.

| Disadvantage | Explanation |

|---|---|

| Higher cost | More expensive upfront than alternatives |

| Skin irritation | Fibers can cause itching or discomfort |

| Heavier weight | Harder to install in some cases |

| Needs careful cutting | Tools must be sharp and handled safely |

Conclusion

Mineral wool insulation delivers excellent soundproofing, fire resistance, and durability, but comes with higher cost and handling challenges.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions