Is Mineral Wool Good for Soundproofing?

Many struggle with noise problems at home or work, and finding a working soundproofing solution can feel impossible. I know how much a little peace and quiet is worth.

Mineral wool, especially rock wool insulation, is one of the best materials for soundproofing thanks to its dense structure and excellent acoustic properties. It absorbs sound waves, reduces echo, and minimizes transmitted noise between rooms.

Noise issues can disrupt daily life and productivity. As someone who helps global clients solve these problems every day, I have seen mineral wool make a difference in everything from homes to heavy industry. But mineral wool is not perfect. Let’s explore what makes it good for soundproofing and where it might fall short.

Is Mineral Wool Good for Soundproofing?

Noise can travel through walls and ceilings, making it hard to concentrate or relax. Many ask if mineral wool really blocks these sounds.

Mineral wool insulation is highly effective for soundproofing due to its dense, fibrous structure. It absorbs airborne noise, reduces echo, and meets ASTM standards for both fire resistance and sound insulation.

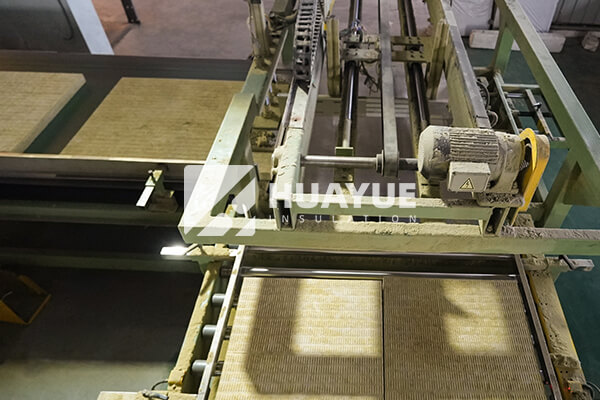

Mineral wool offers real value for soundproofing. I often recommend it to industrial clients like Hans Müller in Germany, who manage noisy chemical plants and tanks. The key reasons are in its structure and composition. Mineral wool, including rock wool, is made from volcanic rock melted at high temperatures and spun into fibers. This creates a dense mat that traps sound waves across a broad frequency range, reducing transmission through walls, floors, and ceilings.

Here’s a simple comparison of common insulation materials for soundproofing:

| Material | Sound Absorption | Fire Resistance | Water Resistance | Cost |

|---|---|---|---|---|

| Mineral Wool | Excellent | Class A1 | Good | Moderate |

| Fiberglass | Good | Noncombustible | Moderate | Lower |

| Foam | Decent | Flammable | Varies | Lower/Varies |

The density makes mineral wool great for heavy-duty applications, like tank insulation in factories. It meets strict ASTM and EN standards, so I often see it specified in government and commercial projects. Its Class A1 fire rating means it won’t burn, which is another huge plus for safety. When properly installed, mineral wool can reduce noise by 8–15 decibels, creating quieter, more comfortable spaces in any setting.

What Are the Disadvantages of Mineral Wool?

No product is perfect, even one as trusted as mineral wool. People often wonder about its downsides.

Mineral wool can be more expensive than fiberglass, may irritate skin during installation, and can settle if not properly supported. It also requires careful handling to maintain its performance.

Over years of advising on building upgrades, I have seen a few places where mineral wool needs improvement. First, the cost is often higher than basic fiberglass or some types of foam. That can be a big factor, especially for large projects or budget-sensitive jobs. Second, mineral wool fibers can irritate the skin, eyes, and lungs during installation. I always tell customers to wear long sleeves, gloves, and a mask when handling it.

There’s also the issue of settling. If mineral wool panels or batts are not tightly packed or properly supported in a wall or tank structure, they may compress over time, reducing their sound and thermal performance. That’s why, as a manufacturer, my team at HUAYUE puts great effort into precision sizing, firm packaging, and quality control. For special projects, I recommend custom-cut panels or rolls to ensure a perfect fit.

Here’s a short table outlining the main disadvantages:

| Disadvantage | How to Mitigate |

|---|---|

| Higher Cost | Buy in bulk or use where benefits are vital |

| Skin/Respiratory | Wear protective gear, ventilate space |

| Settling | Use precise sizing, professional install |

By considering these factors and following best practices, many customers find mineral wool a smart, long-term investment for soundproofing and safety.

How Effective Is Rock Wool for Soundproofing?

Questions remain about how strong rock wool’s soundproofing actually is, especially in comparison to other insulation materials.

Rock wool is highly effective for soundproofing. It absorbs up to 90% of airborne noise, offers Class A1 fire resistance, and delivers stable performance even in challenging industrial environments.

I work with plant engineers like Hans Müller, whose top priorities are cutting noise and meeting strict safety standards. For large storage tanks and facility walls in chemical plants, rock wool’s dense fibers absorb both high and low frequencies. Even when loud machinery is running, adding rock wool can reduce noise transfer significantly, protecting workers’ hearing and boosting comfort.

The following table shows why many industrial clients choose rock wool above other options:

| Application | Sound Reduction | Stability | Fire Safety | Customization |

|---|---|---|---|---|

| Industrial wall panels | Excellent | Won’t sag | Best (A1) | Yes |

| Tank insulation | Outstanding | Long life | Best (A1) | Yes |

| Ceilings and floors | Very good | Good | Best (A1) | Yes |

HUAYUE’s rock wool meets ASTM standards and is used in places where noise reduction, safety, and durability are critical. Our products are also customizable in size, thickness, and packaging, giving each customer the best solution for their unique needs. I always say, if you need soundproofing with proven results and high fire safety, rock wool is a top choice.

Conclusion

Mineral wool, especially rock wool, stands out as a soundproofing solution—strong, reliable, safe, and customizable for almost any project.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions