Foil Faced Mineral Wool Insulation: Is It Really the Best Choice for Your Project?

Mineral wool insulation with foil facing promises high performance, but many struggle to choose the right type for their industrial needs.

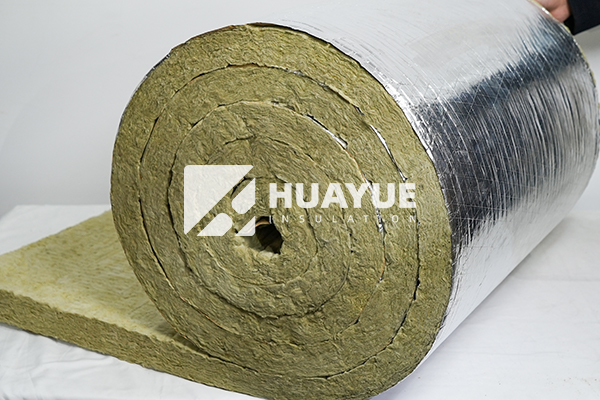

Foil faced mineral wool insulation combines the benefits of high thermal resistance, improved moisture control, and enhanced protection against fire. It works well in environments where durability, lifespan, and safety are top priorities like industrial tanks and pipe systems.

Selecting proper insulation impacts everything from operational safety to long-term costs. Mineral wool stands out for its fire resistance and acoustic properties. The addition of foil facing increases moisture resistance and radiant heat performance. Understanding options like faced, unfaced, and full foil wrap is crucial for anyone responsible for tanks and manufacturing facilities.

Is Foil or Wool a Better Insulator?

Foil and mineral wool each offer distinct insulation benefits, but which one comes out on top for industrial use?

Mineral wool insulates by trapping air and slowing heat transfer. Foil reflects radiant heat and acts as a vapor barrier. When combined, foil-faced mineral wool delivers excellent performance: mineral wool provides high R-value and fire resistance, while foil enhances moisture resistance and keeps radiant heat out.

I have considered both for large chemical tank installations. Mineral wool alone offers solid thermal and acoustic protection, but it can absorb moisture. Foil by itself cannot insulate well, yet it controls vapor and radiant heat. In tanks exposed to harsh weather or chemical vapors, combining foil with mineral wool is ideal.

| Material | R-value | Fire Resistance | Moisture Barrier | Application |

|---|---|---|---|---|

| Mineral Wool | High | Excellent | Moderate | Tanks, Pipes |

| Foil Facing | Moderate (Reflects radiant heat) | None | Outstanding | Over substrate |

| Foil-Faced Mineral Wool | Very High | Excellent | Superior | Tanks, Cryogenics |

In most cases, I recommend foil-faced mineral wool for industrial environments where both high insulation and moisture protection are critical.

Which Way Should Foil-Faced Insulation Face?

Foil faces are often misunderstood—so which direction should they go for best results?

Foil-facing should always be installed facing the warm side of the structure, pointing toward where heat is sourced or expected to radiate. This maximizes the foil’s reflective properties and ensures the vapor barrier functions as designed.

I learned this from supervising cryogenic tank projects. For example, when insulating an outdoor tank in Germany, the foil-faced side was fitted inward, facing the tank wall, trapping warmth and shielding against condensation. Facing the cooler, exterior ambient air would reduce the foil’s effectiveness and cause possible condensation inside the insulation.

| Installation Scenario | Foil facing direction | Reason |

|---|---|---|

| Cryogenic Tank Exterior | Toward tank wall | Stops heat loss and condensation |

| Indoor Heated Pipe | Toward heated surface | Maximizes vapor barrier |

| Living Space Wall | Toward room interior | Retains warmth, blocks vapor |

Correct orientation is key. Installing the foil incorrectly can allow moisture penetration and compromise thermal performance.

Is There Faced Mineral Wool?

Does mineral wool always come faced, or do you need to choose a specialty version?

You can get mineral wool insulation in both faced and unfaced versions. Faced mineral wool features a covering—like foil or fiberglass mat—that adds specific benefits for moisture, radiant heat, or vapor control.

I have reviewed dozens of products as part of facility upgrades. In high-moisture areas like chemical plants or exterior tanks, we chose foil-faced mineral wool exclusively. In less demanding locations, unfaced mineral wool is sometimes used for cost savings, but only when moisture is not a problem.

| Type | Facing | Main Benefit | Typical Use |

|---|---|---|---|

| Unfaced Mineral Wool | None | Acoustic, Fire | Low humidity environments |

| Foil-Faced Mineral Wool | Foil | Moisture, Fire | Tanks, Outdoor pipes |

| Fiberglass-Faced Mineral Wool | Glass Mat | Durability | H.V.A.C., Ducts |

So, yes, faced mineral wool—especially foil-faced rockwool—is widely available to suit rigorous industrial needs.

What are the Disadvantages of Foil Insulation?

Foil insulation sounds perfect, but does it come with any drawbacks for heavy industry?

Foil insulation can crush or tear easily and may not perform well if punctured. If the foil is damaged, moisture can seep into mineral wool, leading to corrosion under insulation (CUI) or reduced performance.

In practice, I have repaired torn foil on chemical tanks many times. Small punctures caused condensation problems and forced early replacement. Foil insulation also requires flawless seam sealing and correct orientation. Ongoing inspection and maintenance are necessary, especially in high-traffic area installations.

| Issue | Impact | Solution |

|---|---|---|

| Physical Damage | Loss of moisture barrier | Reinforced installation |

| Poor Sealing | Vapor penetration | Skilled labor |

| Limited Flexibility | Difficult on irregular shapes | Custom fit panels |

Despite these challenges, I find the upsides far outweigh the risks—especially when installed correctly.

Can You Get Faced Rockwool Insulation?

Is faced rockwool insulation available for demanding industrial uses?

Faced rockwool insulation is widely available. You can order it with foil, glass mat, or customized facings for different industrial requirements. Many manufacturers offer it for cryogenic tanks, pipework, and petrochemical facilities.

I rely on foil-faced rockwool as part of almost every new tank build. It’s fire-resistant, stable over decades, and handles the tough conditions inside and outside a chemical plant. For Hans Müller and engineers like him, faced rockwool insulates tanks, lowers maintenance costs, and ensures long-term safety.

| Facing Type | Fire Safety | Moisture Protection | Longevity | Use Case |

|---|---|---|---|---|

| Foil | Excellent | High | 30+ years | Cryogenic tanks |

| Glass Mat | Good | Moderate | 25-30 years | HVAC, piping |

| Paper | Limited | Low | 5-10 years | Light duty walls |

Whether you need insulation for hot tanks, cold tanks, or hazardous environments, faced rockwool is a proven solution.

Conclusion

Foil faced mineral wool insulation delivers maximum fire safety and moisture protection when installed and maintained correctly.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions