Fire Rated Rock Wool Insulation: Is Rock Wool the Best Choice for Fire Safety?

A fire can threaten a building’s safety faster than almost anything else. Many insulation options claim to be fire rated, but how can you tell which is safest?

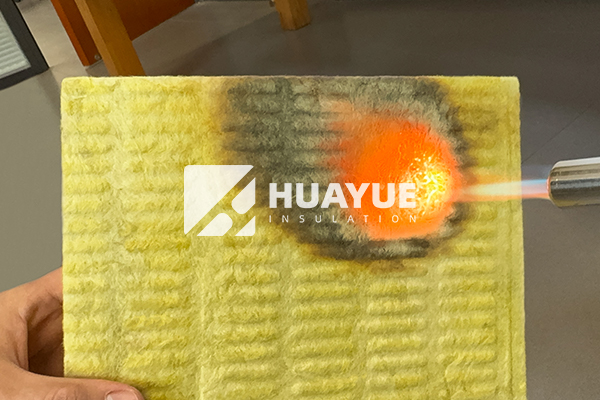

Rock wool insulation is highly fire rated and can withstand temperatures up to 700°C. It earns a Class A rating under ASTM E84 testing, which is ideal for fire safety in buildings.

Choosing the right insulation is not simple. Some materials only provide modest fire resistance. Rock wool, especially HUAYUE rock wool, sets a higher standard. It is rated higher than many alternatives. If protecting your facility from fire risk is your priority, it pays to know how insulation holds up when exposed to heat, how fire ratings are tested, and what numbers truly matter.

Is ROCK WOOL insulation fire rated?

Rock wool claims fire resistance at higher temperatures compared to other insulation products. How reliable is this promise?

Rock wool insulation has a proven fire rating and passes stringent tests such as ASTM E84. It earns a Class A fire rating, making it suitable for fire protection in buildings and industrial tanks.

Rock wool insulation stands out among other options because it is made from natural minerals that withstand much higher temperatures. For example, HUAYUE’s rock wool can handle up to 700°C before breaking down, while other conventional insulation products often stop performing well around 500°C. To earn a Class A rating, an insulation product must limit flame spread and smoke production during the ASTM E84 test. The test uses controlled flames and measures how the material behaves over time. Not every product claiming to be “fire rated” passes this certification. Glass wool and fiberglass are widely used, but their maximum working temperatures are often lower. Many customers—especially those responsible for critical safety installations like tanks—should look for products with verified ratings.

| Material | Max Temp (°C) | ASTM E84 Rating | Fire Classification |

|---|---|---|---|

| HUAYUE Rock Wool | 700 | Passed | Class A |

| Conventional | 500 | Variable | Often Class B/C |

| Fiberglass | 500 | Variable | Class B |

This table shows HUAYUE rock wool’s higher fire tolerance. It explains why engineers responsible for critical asset safety choose it.

Can ROCK WOOL be used for fire blocking?

How does rock wool perform as fire blocking material in walls, floors, and industrial tanks?

Rock wool is recognized as an excellent fire blocker in building codes. Its non-combustible mineral fiber stops heat and fire from passing through gaps and cavities.

Fire blocking is a special use in buildings. It stops flames from moving between rooms or floors, giving people time to escape. Rock wool works well because its dense mineral structure blocks heat and fire very effectively. When installed in wall or floor penetrations, it creates a barrier that can contain a blaze for well over an hour, depending on wall assembly and thickness. Engineers often specify rock wool in fire-rated partition walls or insulated penetrations around pipes and ducts, especially in commercial settings and areas that handle chemicals. Unlike foam or cellulose, rock wool does not melt, drip, or give off toxic smoke. Proper installation takes care to pack the material tightly, seal joints, and keep the product free from gaps, so its fire-blocking ability stays strong. Rock wool is tested for use as a fire stop and is included in many international building standards.

| Application | Fire Blocking Performance | Typical Duration |

|---|---|---|

| Wall/floor penetrations | Excellent | 1–2 hours |

| Pipe jacket insulation | Excellent | 1–2 hours |

| Roof/floor cavities | Very Good | 1 hour+ |

Is ROCK WOOL a 1 hour fire rating?

Many building codes require at least one hour of fire resistance. Does rock wool insulation meet this threshold?

Rock wool can easily meet a 1 hour fire rating when installed according to tested assemblies. Many systems using rock wool extend fire protection beyond 60 minutes.

Designers and engineers often select insulation to comply with local fire codes. The 1 hour fire rating is a benchmark for many walls, floors, and equipment enclosures. With rock wool, it’s not the insulation alone that is tested—it’s also the complete wall or floor system. For instance, a standard partition wall with rock wool insulation and fire-resistant board can pass rigorous laboratory tests, remaining intact and blocking flames for over an hour. HUAYUE’s product is certified to survive direct exposure to flames, preserving its integrity long after other insulations have failed. Customers seeking reliable 1 hour performance must read the certification details. The rating depends on material thickness, installation, and tested assembly. Always follow manufacturer guidelines and local codes.

| System Setup | 1 Hour Fire Rating | Notes |

|---|---|---|

| Rock wool + fire drywall | Yes | Certified system |

| Rock wool in steel tank | Yes | With proper design |

| Rock wool + mineral board panel | Yes | Third-party tested |

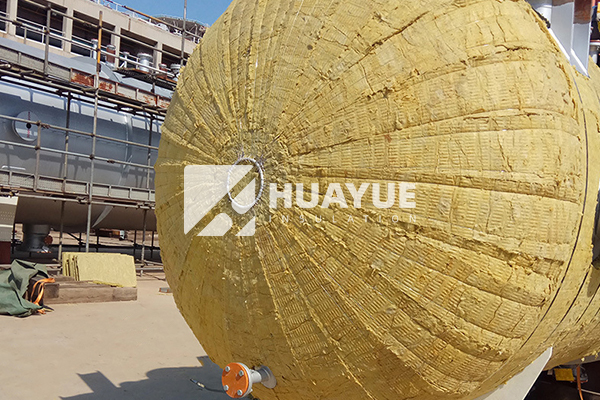

What is the fire rating of ROCK WOOL rigid insulation?

Rigid insulation boards are used in tanks, roofs, and walls. How does their fire rating compare to other formats?

Rock wool rigid insulation typically achieves Class A rating, withstanding high temperatures, and performs consistently under rigorous ASTM E84 tests.

Rigid rock wool panels are designed for easy installation, especially where surface flatness and high load-bearing capacity matter. Their fire rating matches loose-fill and batt versions because the core mineral properties do not change. Rigid panels have the added benefit of staying in place even after prolonged high-temperature exposure, maintaining their shape and supporting other construction materials. HUAYUE’s rigid boards are certified with ASTM E84 Class A. This means they satisfy the strictest fire codes in most countries. Panels can be cut and fitted easily around tank surfaces, boiler walls, or partition structures. For customers who plan critical systems and need to minimize the risk of fire propagation, rigid rock wool is a go-to choice. Always check that supplied panels are fully certified and appropriate for your application.

| Format | Fire Test Used | Fire Rating | Use Case |

|---|---|---|---|

| Rigid board | ASTM E84 | Class A | Wall, roof, tanks |

| Semi-rigid/slab | ASTM E84 | Class A | Pipe, duct, floors |

| Loose-fill/batt | ASTM E84 | Class A | Attic, cavity, retrofit |

Is ROCK WOOL more fireproof than fiberglass?

Fiberglass is popular, but is rock wool actually more fireproof?

Rock wool is significantly more fireproof than fiberglass. It withstands higher temperatures and passes stricter fire resistance tests.

Fiberglass is seen everywhere, but its fire resistance is lower than rock wool’s. Fiberglass can handle temperatures up to 500°C, while rock wool takes on 700°C before losing strength. That extra margin means rock wool stays stable when a fire is intense. Rock wool also does not melt or produce toxic smoke when exposed to flame. Some fiberglass products meet fire codes, but not all achieve Class A ratings. Fire resistance matters most when you need to protect infrastructure, machinery, or tank contents from disaster. Many facility managers choose rock wool, like HUAYUE’s, for its proven performance under high-heat scenarios. The higher tolerances also help keep structures safe for longer periods during a fire, buy more time for emergency response, and reduce life cycle costs due to fewer replacements and repairs.

| Property | Rock Wool | Fiberglass | Effect on Fire Safety |

|---|---|---|---|

| Max temp (°C) | 700 | 500 | Fireproof margin |

| Class A rating | Yes | Often = B | Building code compliance |

| Melting/dripping | None | Possible | Smoke/toxin generation |

Conclusion

Rock wool insulation delivers high fire ratings, superior heat resistance, and reliable protection that meets safety code requirements for modern industrial applications.

"

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions