Fiberglass Pipe Insulation B2B: How Do You Choose the Best Solution?

Many bulk buyers worry about finding the right fiberglass pipe insulation for safety, efficiency, and reliability. The wrong decision can cost money and hurt your reputation.

Fiberglass pipe insulation is ideal for B2B buyers looking for a safe, effective, and cost-efficient way to keep pipelines protected from heat loss, condensation, and corrosion. It is easy to custom-fit for industrial, commercial, and residential projects.

Whether you manage a chemical plant or handle procurement for a construction project, choosing the best fiberglass pipe insulation impacts safety and efficiency. I have helped many customers like Hans find the right balance. Let me break down the most common questions I get, and show you how to solve them for your next project.

What fiberglass insulation to use for crawl space?

Wet, dark crawl spaces are tough to insulate. Problems like moisture, mold, and pests can ruin insulation fast.

Use faced fiberglass batts or rolls rated for below-grade spaces. Look for products with foil or vapor barriers that withstand moisture and fit tight between joists or around pipes, stopping energy loss and helping prevent condensation.

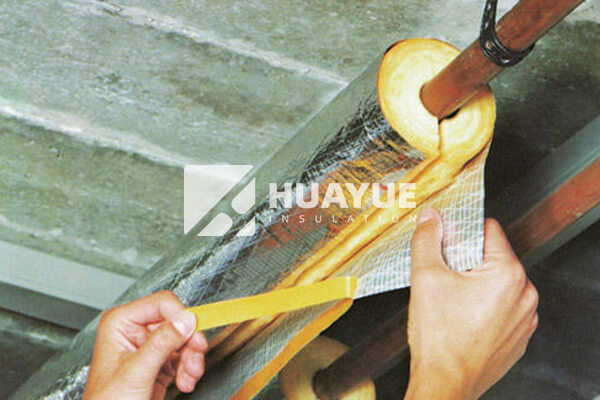

Crawl spaces need insulation that will work under harsh conditions. Standard fiberglass batts come in different types. The faced batts have a vapor barrier, usually made of paper or foil, which blocks water and acts as an extra defense against mold and mildew. Unfaced batts are good in dry places, but most crawl spaces face damp problems. The best practice is to measure the joist spacing in your crawlspace and order insulation cut to fit snugly, so there are no gaps. Also, sealing the joints and using mechanical fasteners keeps the insulation in place over years, even in areas with temperature swings or pests. The vapor barrier side always faces the warmest area. In most homes, that means paper or foil faces upward toward the floor above. I once helped an industrial client retrofit crawl space insulation under old water pipes. We used thick-faced glass wool, and it solved both condensation and rodent problems. For large orders, like those we handle at HUAYUE, the right product with proper customization saves hours of labor onsite.

Is fiberglass pipe insulation safe?

Safety is a big concern for plant engineers and building owners. Clients worry about health risks from using fiberglass.

Fiberglass pipe insulation is safe when installed and maintained correctly. Modern products are formaldehyde-free, non-combustible, and certified to reduce dust and airborne fibers during installation.

Fiberglass insulation is made by spinning molten glass into fibers. Some people remember old stories about skin irritation or inhaling fibers. Most modern fiberglass pipe insulation is different. Many products now use binders that do not contain formaldehyde, which means cleaner air in buildings. European and U.S. standards regulate fiber size, so manufacturers like us can control airborne dust. When working with insulation, workers should wear gloves, masks, and goggles for extra caution, just like when handling mineral wool or other industrial materials. Once installed, the insulation is covered—by aluminum cladding, PVC jacketing, or sealed inside walls—so it does not shed fibers into the air. For schools, hospitals, or chemical plants, we recommend certified products like those from HUAYUE, which carry CE and SGS marks and meet all global safety standards. We once supplied insulation for a school near Beijing, and the testing confirmed almost zero airborne fibers after installation. By following proper guidelines, you can keep your staff and tenants safe.

Can fiberglass pipe insulation be used outside?

Lots of people ask if fiberglass insulation can survive rain, snow, and sunlight outside. If you install the wrong insulation, you may end up paying for repairs you could have avoided.

Fiberglass pipe insulation can be used outdoors if you add weatherproof jackets—like aluminum, stainless steel, or UV-rated PVC—so that the insulation itself is never exposed to water or sunlight.

Outdoor insulation faces a tough environment. Water, ice, sun, and even birds or insects attack unprotected materials. Fiberglass pipe insulation is not waterproof; it absorbs water if left open. But it is a good thermal insulator and stays stable in wide temperature ranges. That is why the best way is to wrap it with a protective layer. At HUAYUE, for outdoor pipelines, cold or hot, we recommend fiberglass pipe sections covered with factory-laminated aluminum foil, stainless steel, or UV-stable PVC jackets. These covers keep rain, snow, and UV rays away from the insulation. Engineering specs often call for double-sealed joints and proper end caps as well. Our factory provides ready-to-install insulation kits, custom cut for each project. For example, on a recent project in South America, we shipped pre-jacketed fiberglass pipe sections, so the installers could simply snap the covers shut and add sealant—no extra labor in the field and no worry about insulation getting wet.

Which is better, foam or fiberglass pipe insulation?

Some buyers are torn between foam and fiberglass insulation. Each has its supporters, but the best choice depends on your needs.

Fiberglass has a higher temperature range, is non-combustible, and resists UV better. Foam insulation absorbs less water but may cost more and burns or melts at lower temperatures.

When choosing between foam and fiberglass for pipes, start by looking at these differences:

| Property | Fiberglass | Foam |

|---|---|---|

| Max Temperature | Up to 540°C (glass wool) | 100-120°C (elastomeric foam) |

| Fire Resistance | Non-combustible | Burns or melts |

| Water Absorption | Absorbs if not protected | Low with closed cell structure |

| Outdoor Durability | Needs jacket | Needs jacket |

| Cost (industrial scale) | Usually lower | Often higher |

| Sound Absorption | Very good | Average |

I usually ask: Is your pipe hot or cryogenic? Outdoors or indoors? Hot pipes (like steam or process lines above 120°C) need fiberglass. For cold water or chilled lines inside a building, foam works because it stops condensation better and is easy to handle. But in places like chemical plants or oil refineries, fiberglass is preferred for its fire safety and stability. Foam is better if space is tight and you need a closed-cell solution that stops water. We have supplied both, depending on the job. A chemical tank farm in North China needed fiberglass because of fire safety rules. But some data centers prefer foam for cold water pipes, because installation goes quicker. It really comes down to your temperature, fire rating, and durability needs. That’s why I always ask customers to share their technical specs so we can recommend the right fit.

Conclusion

Choosing the right fiberglass pipe insulation depends on your location, safety needs, regulations, and budget. Matching the product to your project ensures long-term success for any B2B partner.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions