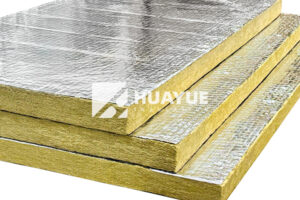

Why Is Mineral Fiber Batt Insulation the Best Choice for Building Projects?

When facing insulation decisions, many options look similar. Yet, a wrong choice can lead to wasted energy and unexpected safety risks.

Mineral fiber batt insulation is fire-resistant, easy to install, and delivers excellent thermal performance. It meets strict ASTM standards, making it a reliable solution for building projects.

If you want to protect your building, lower costs, and meet regulations, pick insulation that delivers on performance and safety. Let’s look at why mineral fiber batt insulation is trusted by professionals worldwide.

How Does Mineral Fiber Batt Insulation Perform Against Fire Hazards?

Fire risk haunts building owners. Mineral fiber batt insulation offers strong fire resistance, promising peace of mind and regulatory compliance.

Mineral fiber batt insulation is rated Class A1 for fire safety, which means it will not ignite or contribute to fire spread. It keeps buildings safer, reduces damage, and meets global safety codes.

Mineral fiber batt insulation is made from inorganic fibers like basalt and slag. These raw materials are melted, spun into fibers, and shaped into batts. Because mineral fibers do not burn, Class A1 fire rating is achieved. I often see fire tests in our labs, where we expose mineral fiber batts to flames. The results are always the same—the insulation does not catch fire or add fuel to it.

This fire safety is crucial, especially in commercial and industrial buildings. For example, high-rise constructions require Class A1 insulation to protect lives and property. Authorities across Europe, North America, and Asia require these standards. Our global customers tell me fire prevention is the top reason they select mineral fiber batts over organic materials. The product stays stable even under extreme heat, unlike foam or plastic insulations that can melt or release toxic smoke.

| Feature | Mineral Fiber Batt | Foam Insulation |

|---|---|---|

| Fire Safety Rating | Class A1 | Class B/C |

| Combustibility | Non-combustible | Combustible |

| Smoke/Toxin Release | None | Possible |

| Compliance (ASTM/EN) | Yes | Conditional |

Choosing mineral fiber batt insulation means investing in long-term safety and regulatory peace of mind. That’s why so many customers insist on this material.

Can Mineral Fiber Batt Insulation Improve Thermal Efficiency?

Insulation performance affects everything from energy bills to room comfort. Mineral fiber batt insulation delivers dependable results, season after season.

Mineral fiber batt insulation traps air within its dense fiber matrix, reducing heat transfer. Buildings stay warmer in winter and cooler in summer, slashing energy costs for heating and cooling.

I have witnessed shipments to cold regions in Europe and hot climates in Asia—all with positive feedback. The fibrous structure slows down heat flow, performing well in walls, ceilings, and roofs. Contractors report fewer gaps and easier installation than with rolled or blown insulation types. The batts are rigid enough to fit snugly, minimizing air leaks.

In addition, our mineral fiber batt products have low thermal conductivity values (as low as 0.035 W/(m·K)), which is documented to meet ASTM and EN standards. When installed correctly, thermal bridges are almost eliminated. This not only improves comfort but has a direct impact on reducing monthly utility costs. One customer in Scandinavia told me their radiant heating became more effective after switching to mineral fiber batts in their apartment blocks.

| Property | Value |

|---|---|

| Thermal Conductivity (λ) | 0.035 W/(m·K) |

| Installed R-Value | 3.5-4.2 per inch |

| Air-tightness | High |

| Application Areas | Walls, Roofs |

These numbers mean real savings and better living environments. That is why mineral fiber batt insulation remains top choice in energy-efficient projects.

How Customizable Is Mineral Fiber Batt Insulation for Large Projects?

Standard products often fall short. Mineral fiber batt insulation can be tailored in size, density, and packaging to fit virtually any project requirement.

Our factory can produce mineral fiber batts as panels, rolls, or pipes. We handle orders that require custom sizes, thickness, or density, matching exact specifications. Packaging can be designed for local conditions or international shipping needs. I have worked with clients needing special packaging for weather, warehouse, or export issues. We adapt quickly to keep projects on schedule.

For wholesale customers or large contractors, bulk orders are handled with efficient logistics thanks to our location near major seaports. I have coordinated with buyers across Europe, the Middle East, and North America. Their feedback consistently highlights delivery speed and reliability. This flexibility extends beyond product specs—we help design systems for unique buildings, such as storage tanks or special machinery rooms.

| Customization Option | Details |

|---|---|

| Product Forms | Panel, Roll, Pipe |

| Sizes | Custom by request |

| Density | Variable (per application) |

| Packaging | Designed for local/export use |

| Regulatory Standards | ASTM, EN, local codes |

You always get what you need—no more, no less. This ability to custom-fit solutions makes mineral fiber batt insulation a preferred choice for OEMs and contractors.

Does Mineral Fiber Batt Insulation Hold Up in Harsh Environments?

Some insulation materials suffer in cold, wet, or chemically aggressive environments. Mineral fiber batt insulation stands up to harsh weather and tough industrial conditions.

Mineral fiber batts resist moisture, mold, and chemicals. They maintain performance in extreme temperatures, from freezing cold to high heat. Their durability prevents shrinkage, warping, or breakdown, ensuring long-term insulation value.

I have seen our mineral fiber batts used inside chemical plants, refineries, and cryogenic storage tanks. Customers appreciate the fact that rock wool insulation does not absorb water—so there is no risk of corrosion under insulation (CUI). The product is also proofed against common industrial chemicals. Maintenance teams report that the material stays intact year after year, even when exposed to fluctuating weather or temperature swings.

From my experience, the resilience of mineral fiber batt insulation saves building owners on costly repairs and replacements. When material lasts longer, overall life cycle costs drop.

| Challenge | Mineral Fiber Batt Performance |

|---|---|

| Moisture Resistance | Excellent |

| Chemical Stability | High |

| Temperature Range | -200°C to +750°C |

| Longevity | Over 20 years |

| CUI Prevention | Yes |

This kind of reliability gives peace of mind—your investment will last, no matter how tough the environment.

What Regulatory Standards Can Mineral Fiber Batt Insulation Meet?

Regulations can change. Mineral fiber batt insulation is made to meet global standards for safety, quality, and environmental responsibility.

Our mineral fiber batt products comply with ASTM in America, EN in Europe, and other local codes. Testing covers fire resistance, thermal performance, and composition. Our facilities maintain ISO 9001, ISO 14001, and ISO 45001 certifications. Every batch gets tested and traced, ensuring each shipment is up to standard.

I work directly with procurement teams who need documentation and third-party validation. Our rock wool batts regularly pass tests by SGS and CE authorities. This makes it easier for contractors and importers to meet local building requirements, pass inspections, and avoid project delays.

| Regulatory Body | Certification | Application |

|---|---|---|

| ASTM | Yes | US/Global |

| EN | Yes | EU |

| ISO 9001/14001/45001 | Yes | Global |

| CE, SGS | Yes | Export |

Regulatory confidence matters. When you use mineral fiber batt insulation, you make sure your project is safe, legal, and future-proof.

Conclusion

Mineral fiber batt insulation provides fire safety, thermal efficiency, durability, customization, and regulatory compliance—making it the reliable choice for modern buildings.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

# Is Fiberglass Insulation Dangerous?

Feb 26, 2026

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions