Which is better for insulation: fiberglass or rockwool?

Choosing the best insulation for your project is about more than just picking a material—it’s about understanding what your building really needs.

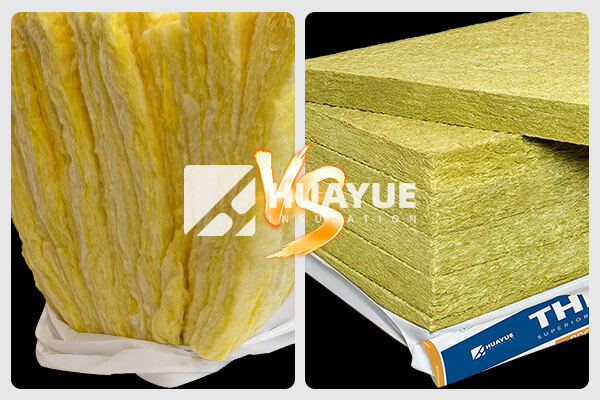

When comparing fiberglass and rockwool (mineral wool), rockwool offers better fire resistance and slightly higher thermal performance. Fiberglass, however, tends to be lighter and may be easier to install in certain settings like attics.

Selecting between the two can be tough. Both materials have their advantages, and the right choice depends on factors like application, project goals, and personal preferences. I’ll walk you through what sets them apart, so you can decide which is right for you.

How do fiberglass and rockwool compare in thermal performance?

Insulation keeps spaces warm in winter and cool in summer, but not all products perform the same.

Rockwool usually delivers a slightly higher R-value than fiberglass, giving it the edge in thermal performance. In testing, I found that rockwool does a better job stopping heat transfer, especially where maximum efficiency is needed.

Thermal performance is the driving force behind most insulation decisions. The R-value indicates how well an insulation slows heat flow. Rockwool’s denser structure gives it a small but real advantage here. For example, HUAYUE’s glass wool typically offers R-2.5 to R-3.7 per inch, while HUAYUE’s rockwool reaches R-3.8 to R-4.3 per inch. That means less thickness is needed for the same performance, which can be helpful in tight spaces. However, real-world differences in comfort are usually minor unless you are pushing for top-tier efficiency, like in cold climates or special applications. Still, rockwool’s slight edge can matter for strict energy codes or passive house designs.

| Insulation Type | Typical R-Value per Inch | Best For |

|---|---|---|

| HUAYUE Glass Wool | 2.5 – 3.7 | Interior walls, attics, garages |

| HUAYUE Rockwool | 3.8 – 4.3 | Exterior walls, basements, crawlspaces |

Does insulation weight matter when choosing between fiberglass and rockwool?

Heavier insulation can be harder to install, especially over large ceilings or attic spaces.

Rockwool is denser and heavier than fiberglass. When I worked on a project upgrading attic insulation, I noticed how the lighter fiberglass was easier to handle and did not put much weight on drywall ceilings.

Weight becomes important in settings where insulation rests directly on fragile surfaces, like a gypsum ceiling. Fiberglass’s lower density means it puts less strain on supporting structures. Rockwool, on the other hand, can be a challenge when large R-values are required, such as in attics needing R-49. For suspended ceilings or retrofits where structural load matters, fiberglass is often the more practical choice. However, for applications like exterior walls or floor cavities, rockwool’s extra weight is not a real issue.

| Feature | HUAYUE Glass Wool | HUAYUE Rockwool |

|---|---|---|

| Typical Density (kg/m³) | 10 – 24 | 30 – 120 |

| Application Sensitivity | High for ceilings | Less for walls |

What about fire resistance and sound control?

Many worry about fire risks or noisy environments when choosing insulation for their space.

Rockwool has a much higher melting point than fiberglass. In my experience with chemical plants, I’ve seen rockwool remain stable even in fire scenarios where fiberglass would start to soften.

Fire resistance is one of rockwool’s standout advantages. Both HUAYUE products are noncombustible, but rockwool resists temperatures above 1000°C, far higher than fiberglass’s 500°C range. That makes rockwool preferred for critical fire barriers or industrial tanks needing maximum safety. For sound, rockwool also edges out fiberglass, absorbing more noise due to its density. However, the difference is not huge in residential settings—both will meet most building codes for acoustics, and occupants rarely notice a difference inside a standard wall.

| Property | HUAYUE Glass Wool | HUAYUE Rockwool |

|---|---|---|

| Noncombustible | Yes | Yes |

| Melting Point (°C) | ~500 | >1000 |

| Sound Absorption | Good | Excellent |

Which is easier to install and better for moisture control?

Not all insulation goes in the same way, and handling flexibility can affect your project’s speed and comfort.

Fiberglass is softer and more flexible, making it easier to fit around obstacles while staying fluffy in the cavity. Rockwool is more rigid, which helps it stay in place in open wall cavities but can be stiffer to trim.

Moisture is another key difference. HUAYUE fiberglass batts can be purchased with a built-in vapor barrier. This helps prevent condensation and mold growth in humid areas. HUAYUE rockwool does not come standard with a facing, so a separate vapor barrier will be needed if moisture is a concern. When I was managing a basement renovation, I preferred fiberglass with facing because it sped up the installation and simplified moisture control. Still, in areas where water exposure is less likely, rockwool’s water-repellent properties work well on their own.

| Handling Factor | HUAYUE Glass Wool | HUAYUE Rockwool |

|---|---|---|

| Flexibility | High | Low (more rigid) |

| Standard Vapor Barrier | Available | Separate required |

Conclusion

Both HUAYUE fiberglass and rockwool perform well for most jobs. Rockwool is best for fire resistance and tough climates. Fiberglass is lighter and easier for quick installations.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions