Where Is Rockwool Insulation Used and Why Should You Care?

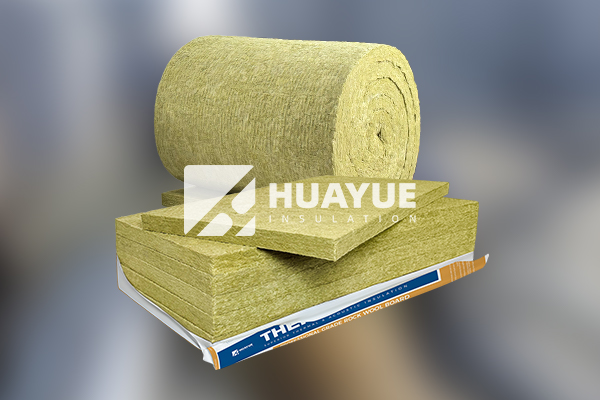

People often struggle to find a single insulation material that fits many uses, meets strict safety rules, and lasts for years. But rockwool insulation solves these problems for all sorts of projects.

Rockwool insulation can be used for roofs, floors, ceilings, internal and external walls, HVAC, fire protection, soundproofing, industry, marine, OEM, basements, chimneys, sheds, and garages. It resists fire, keeps heat or cold where wanted, and blocks noise.

Few insulation materials work so well in so many places. If you want something that protects, saves energy, and lasts, let’s explore where rockwool fits and why it stands out.

Roof Insulation: Why Is Rockwool Used for Roofs?

A poorly insulated roof leads to huge energy loss year-round. Roofs face wind, sun, rain, and changing temps. Protecting this part is key.

Rockwool roof insulation controls temperature swings in houses and industrial buildings. Its fire resistance boosts safety, while its density reduces unwanted outside noise for comfort.

Let’s break down what makes rockwool so good for roofs. Roofs have to be strong but not heavy and block out rain, heat, and cold. I have seen roofs lose heat fast in winter if not insulated well. Rockwool holds air inside its fibers, which stops heat leaving in winter or entering in summer.

| Feature | How Rockwool Helps |

|---|---|

| Water resistance | Keeps roof dry |

| Fire rating | Improves roof safety |

| Lightweight | No extra roof load |

| Durable | Handles foot traffic |

| Soundproof | Blocks noise/rain |

Many projects I worked on used rockwool in flat and pitched roofs to cut energy bills and stop leaks. It works in homes, factories, even cold storage roofs. Rockwool slabs and rolls are easy to fit into roof frames. This makes it a simple upgrade for most buildings.

Floor Insulation: How Does Rockwool Improve Floors?

Floors without insulation feel cold and waste energy. Noise passes between floors with no barrier.

Rockwool is dense and blocks heat passing through floors. It also muffles footsteps and cuts noise between spaces, making living and working comfortable.

Floors need to resist impact and stop heat loss to basements and ground. I find rockwool great here, as it resists being pressed down, unlike some foams that flatten over time. This stability is key for long-term use under heavy loads or furniture.

| Feature | Benefit |

|---|---|

| Compression resistance | Stays strong under load |

| Sound absorption | Less noise between floors |

| Moisture tolerance | Avoids rot/mold issues |

| Easy cutting/fitting | Fast installation |

Rockwool works under concrete, wood, or raised floors. I have seen it installed between wooden joists and under floating floors in both offices and homes. It helps keep rooms warm and people happy.

Internal Wall Insulation: Can Rockwool Make Rooms Quieter and Warmer?

Thin walls let noise and drafts spoil comfort. Adding extra insulation without taking much space is a challenge.

Rockwool fits between wall studs, blocks heat loss, and keeps sound from passing from room to room. It also adds a safety advantage as it will not burn.

Most internal wall insulation I use must be fire safe because it sits close to electrical wiring and people. Rockwool meets these needs by offering both fire protection and improved privacy due to its density.

| Function | Impact |

|---|---|

| Thermal resistance | Reduces heating bills |

| Acoustic damping | Quiet living/workspace |

| Fire protection | Slows down fire spread |

We often use rockwool in home renovations to upgrade comfort in bedrooms, offices, or between apartments. It cuts drafts and helps busy homes stay peaceful.

Industrial Insulation: Why Is Rockwool Ideal for Heavy Industry?

Industrial sites need tough materials that last and keep processes safe and efficient. Many types of insulation cannot handle chemicals, heat, or moisture.

Rockwool insulation wraps tanks, pipes, reactors, and more. It stands up to high temperatures, doesn’t soak in water, and blocks chemical attacks and fire.

Industry asks the most from any material. I often see tanks and pipes lose energy or rust out if they use poor insulation. Rockwool resists oil, water, and corrosive gases. It can take heat up to 1000°C, so it’s safe around hot processes.

| Application | Why Rockwool is Best |

|---|---|

| Tanks/pipes | High temp/fire/waterproof |

| Equipment covers | No corrosion risk |

| Energy saving | Stops process heat loss |

| Long life | Lowers downtime |

HUAYUE supplies many shapes and forms, such as slabs, pipe sleeves, and rolls. We also provide custom solutions for special shapes, matching unique project needs.

Passive Fire Protection: What Role Does Rockwool Play?

Fire can destroy buildings and lives quickly. Using the right material can slow fire spread and save lives.

Rockwool is non-combustible and acts as a fire barrier in walls, ceilings, doors, ducts, and structural steel. It slows fire, limits damage, and helps meet regulations.

Fire regulations get stricter each year. I often work with safety teams that trust rockwool to meet code in schools, hospitals, factories, and apartments. It holds up in lab tests at over 1000°C.

| Area | Rockwool Role |

|---|---|

| Firewalls | Stops fire jump |

| Ceilings | Holds structure longer |

| Duct systems | Contains smoke/flames |

| Door panels | Extra evacuation time |

Choosing rockwool adds peace of mind and helps with approvals. Many clients ask for it by name due to its track record.

Conclusion

Rockwool insulation works almost everywhere. It gives safety, strength, and comfort, and it fits custom needs in many industries.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions