What is the density of rock wool and how does it affect performance?

Rock wool density can make or break the efficiency of insulation and soundproofing. Not knowing the right density wastes resources and risks safety.

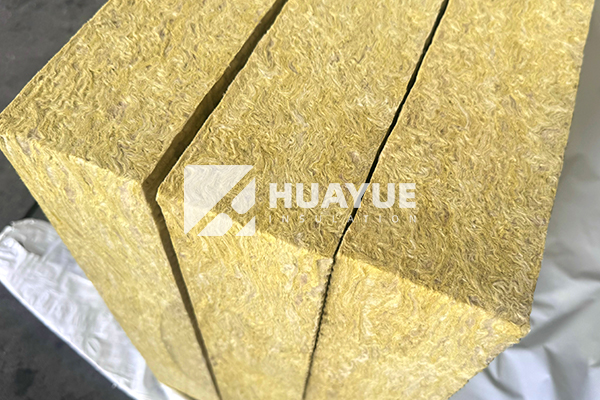

The density of rock wool insulation ranges from 40 kg/m³ to 200 kg/m³, depending on application. Lower density is used for thermal insulation; higher density is preferred for structural and soundproofing needs.

Rock wool density has different effects depending on what the final goal is. If you want to improve sound absorption, prevent condensation, or meet fire protection standards, choosing the right density is essential. It is not only about picking a number; it is about matching the material to your project’s job, lifetime and environment.

What is the density of rock wool?

Ignoring density can make tanks lose heat, lead to corrosion, and even increase maintenance costs. Density determines how well rock wool keeps things safe and efficient.

Most rock wool insulation sold for tanks and pipes runs between 80 kg/m³ and 200 kg/m³. For walls and ceilings, it’s often 40 to 80 kg/m³. These numbers are not random. Manufacturers use strict quality controls to match the end-use requirement.

Rock wool is made from spinning molten basalt at very high temperatures. Changing how tightly the fibers are packed changes the density. More fibers per cubic meter means higher density; fewer fibers, lower density. Higher density means the material is much tougher. It stands up to heavy loads and also helps stop vibrations and shed water during tough weather. Lighter density gives better thermal performance for exterior walls, especially in milder climates where heavy wind and compressive strength are not the primary concerns.

Different densities serve different purposes in industrial projects. For insulation of tanks that need structural soundness, high-density rock wool is often used to make sure there is no sagging and long-term reliability. For cryogenic tanks, material with a tight density protects against condensation and CUI better. I have seen engineers switch to denser product after water damage and mold threatened assets. Sometimes density is the only line between a safe, long-lasting tank and a costly failure.

| Density (kg/m³) | Typical use | Key benefit |

|---|---|---|

| 40 – 80 | Wall & ceiling insulation | Best for thermal insulation |

| 80 – 120 | Pipe and duct insulation | Good for vibration damping |

| 120 – 200 | Tank, roof and structural panels | Load-bearing, soundproofing |

What is the best Rockwool density for sound absorption?

Problems with echoes and noise are frustrating and damage comfort. Not choosing the best density wrecks any chance of good results and will enforce a costly upgrade soon.

The best rock wool density for sound absorption falls between 60 kg/m³ and 120 kg/m³. This range offers a strong mix of fiber structure and air gap, catching more sound waves inside.

Rock wool traps sound because of how the fibers interact with incoming waves. Simply put, lower density rock wool has more air in it. Too much air lets sound travel straight through and does not help. Higher density means the fibers block more sound, but if it is too dense, sound bounces off. The sweet spot is 60–120 kg/m³, depending on whether the job is reducing speech noise, machine rumble or traffic. In projects where I helped redesign mechanical rooms, using 90 kg/m³ density rock wool panels cut noise by half. For offices, lower densities work better for absorbing higher-pitch sounds. Choosing carefully keeps buildings peaceful without extra spend.

| Density (kg/m³) | Sound absorption target | Best for |

|---|---|---|

| 60 – 90 | Speech, light machinery noise | Offices, classrooms |

| 90 – 120 | Low-frequency, heavy machinery | Industrial, mechanical |

What is the density of 25mm Rock wool?

Ignoring thickness and density together often leads to errors in calculations. Both must match; otherwise, insulation will fail when you least expect it.

25mm thick rock wool panels usually have densities from 80 kg/m³ to 150 kg/m³. The choice depends on the application and targeted results.

Thickness and density go together in every project. If you choose 25mm sheets, the density decides how well it performs. In my work on tank insulation retrofits, I have used 80 kg/m³ for exterior thermal insulation. It saves weight and cost. When safety against vibration and fire is needed, 120 kg/m³ panels hold up better. A thinner panel needs higher density to do the same job. Warehouses store both light panels for general coverage and heavy ones for tanks and roofs. Matching both specs is key. One project where density was too low and the panel too thin ended up needing a full replacement that doubled the cost. Knowing both numbers avoids expensive mistakes.

| Thickness (mm) | Recommended Density (kg/m³) | Use Case |

|---|---|---|

| 25 | 80 – 150 | Insulating tanks, pipes |

Conclusion

Rock wool density is more than a number. Choosing the right density is vital for perfect insulation, sound absorption, and reliable lifetime protection.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions