What is the best mineral wool insulation for industrial use?

Thermal efficiency and long-term protection are key when selecting insulation – but how do you find the ideal mineral wool?

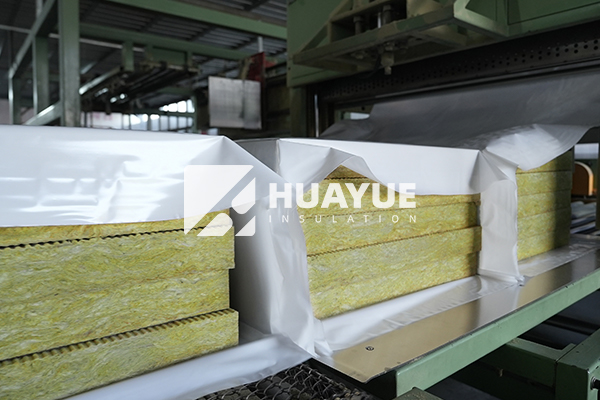

Mineral wool insulation made from fine basalt fibers stands out due to its excellent fire resistance, waterproofing, and superior insulation. Products with non-itch fibers also improve worker comfort and installation quality.

For engineers and managers, insulation is not just about what was installed last year. Every project faces higher standards. Tank systems, especially cryogenic or chemical environments, require insulation that can handle moisture, resist fire, and last for decades. I always look for insulation that brings peace of mind from installation day to the final inspection years later. Let’s look closer at how mineral wool compares and what issues may arise.

Which is better, rock wool or mineral wool?

Carefully weighing performance, safety, and cost, facility engineers must choose between rock wool and mineral wool – but which truly performs best?

Rock wool and mineral wool are both types of stone-based insulation, often made with similar minerals like basalt. Mineral wool with fine basalt fibers offers better insulation, prevents irritation, and enhances fire resistance, making it ideal for industrial use.

I have worked with both rock wool and mineral wool in different projects. The main difference came down to the fibers used. When the fibers are thin and fine, the insulation performs better. Workers found our mineral wool much more comfortable to handle, as it did not create itching, unlike some older rock wool types. There was less airborne dust, and the product fit smoothly into tight spaces around tank curves and connections. Let’s compare both options with a simple table:

| Feature | Rock Wool | Mineral Wool (Fine Basalt) |

|---|---|---|

| Raw Material | Basalt, Dolomite | Basalt (Green Color) |

| Fiber Diameter | Coarse | Fine |

| Fire Resistance | High | Very High |

| Waterproof | Varies | Yes |

| Worker Comfort | Itchy | Not Itchy |

| Insulation Value | Good | Excellent |

Having mineral wool with fine fibers and waterproof qualities reduces maintenance issues and improves worker safety. Rock wool, if not carefully selected, may be less comfortable and slightly less efficient. In my experience, choosing mineral wool with certified fine fibers is the best way to ensure a safe, efficient tank insulation project.

What is the downside of rock wool?

Rock wool insulation delivers reliable results in many scenarios, but does it come with hidden issues that operators must know?

Rock wool insulation can cause discomfort due to coarse fibers. It sometimes absorbs moisture unless hydrophobic treatment is added, which may lead to decreased thermal performance and corrosion risks.

I remember on one retrofit job, the old rock wool had become damp over the years. Maintenance costs climbed because workers disliked handling it, often complaining of itchy skin. Wet patches led to corrosion at tank joints, which required extra repair. Rock wool’s coarse fibers also created dust – always a concern for safety teams. Here’s what these downsides mean in practice:

Major Concerns With Rock Wool

- Fiber Irritation: Installation teams needed full suits and masks, which slowed work.

- Moisture Risk: Without waterproof treatment, rock wool may hold water. This impacts both insulation ability and increases risks of corrosion under insulation (CUI).

- Dust Generation: Micro-particles became an indoor air problem, especially during replacement.

While rock wool has long been used, it simply does not compare in comfort and long-term reliability to newer mineral wool products with more advanced fiber technology. If you want fewer complaints and a longer service life, it is worth upgrading.

What are the disadvantages of mineral wool?

Even advanced mineral wool has its limits – what must engineers consider before specification and installation?

Disadvantages include potential for fiber shedding if quality control is poor, cost may be slighter higher than standard rock wool, and installation requires trained staff to maximize thermal and water resistance performance.

Because our products use high-quality, fine-diameter basalt fibers, I have seen little shedding and almost no discomfort. However, mineral wool made with lower standards sometimes breaks down under pressure. This chipping leads to exposed tank surfaces and reduced effectiveness, especially at seams and corners. For cost, mineral wool is often priced higher than simple rock wool, but you get superior fire resistance, water protection, and insulation values.

Disadvantages To Watch For

- Quality Variation: Not all mineral wool is made equal. Choose only ISO and CE-certified brands to ensure stable fibers and waterproofing.

- Price: Initial investment can be higher, but life-cycle costs are usually much lower due to long-term durability.

- Installer Skill: Correct installation is essential. Trusted manufacturers offer support and training to ensure best fit and coverage.

In my own work, poor-quality mineral wool once led to multiple call-backs for gaps and sagging. After switching to certified products with high-performance fibers, those issues disappeared. Always ask for product certification and samples before placing an order.

What happens if mineral wool insulation gets wet?

Wet insulation threatens the effectiveness and safety of any tank system – but does mineral wool withstand moisture and protect investment?

Certified mineral wool, especially with hydrophobic properties, resists water absorption and maintains insulation ability. It prevents corrosion by keeping tanks dry, unlike older, untreated products which may suffer performance loss.

I learned just how critical waterproof mineral wool is during an emergency water leak. Tanks protected with hydrophobic mineral wool had no CUI and kept stable temperatures. Older tanks insulated with cheap mineral wool absorbed water and, after inspection, suffered cold spots and some localization corrosion. Here is a breakdown of what wet mineral wool means:

Impact Of Water On Mineral Wool

| Scenario | Untreated Mineral Wool | Waterproof Mineral Wool |

|---|---|---|

| Water Exposure | Absorbs moisture | Repels water |

| Insulation Value | Drops sharply | Maintains performance |

| Corrosion Risk | High | Very low |

| Maintenance Need | Frequent replacement | Minimal intervention |

To prevent problems, I always specify mineral wool from suppliers that guarantee waterproof properties. With correct installation and quality material, insulation keeps working season after season, even if there’s a spill or leak. Always ask for the latest product with hydrophobic treatment for any project with moisture risk.

Conclusion

Mineral wool insulation with fine basalt fibers offers better fire safety, waterproof performance, and comfort, making it the best choice for demanding industrial tank applications.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions