What is fiberglass batt insulation?

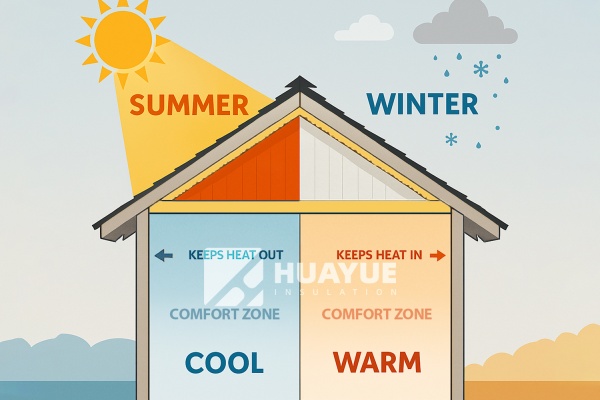

Homeowners, builders, and engineers face one big challenge: how to keep buildings warm in winter and cool in summer without spending too much money.

Fiberglass batt insulation is a type of thermal insulation material made from fine glass fibers. It comes in pre-cut panels or rolls, designed to fit between wall studs, floor joists, and ceiling rafters to reduce heat loss and save energy.

Even though there are many types of insulation, fiberglass batt insulation appears in buildings around the world. As someone who has visited many construction sites, I see it used in everything from homes to huge industrial tanks. Next, let us walk through what makes this insulation so popular, how it performs, and where it shines in the world of building materials.

How does fiberglass batt insulation work?

Many worry about energy leaks and high bills if they choose the wrong insulation. The pressure to pick the right solution can feel overwhelming.

Fiberglass batt insulation traps air within its glass fibers, which slows heat transfer through walls, floors, and ceilings. This helps buildings maintain comfortable temperatures and reduces energy costs year-round.

To understand how fiberglass batt insulation works, think about a thick winter coat. When you zip up your jacket, you trap air near your body, which keeps warmth from slipping out. Fiberglass batt insulation does the same thing for buildings. The spun glass fibers hold still pockets of air and stop heat from passing through quickly. This insulation usually comes in standard lengths and widths to fit most modern construction, making it popular for both new projects and renovations.

Here’s a simple look at how this insulation performs:

| Property | What It Means |

|---|---|

| R-value | Insulation’s resistance to heat |

| Thickness | More thickness = more insulation |

| Fire Resistance | Non-combustible |

| Moisture Resistance | Resists water absorption |

The main advantage for many, especially people like Hans Müller in industrial settings, is how it can help keep a consistent climate inside tanks or buildings, fight condensation, and add a layer of fire protection.

Where is fiberglass batt insulation used most often?

Builders and engineers know that each project comes with its own climate, noise, and safety needs. Picking the wrong insulation could lead to failures down the line.

Fiberglass batt insulation is most commonly used in residential and commercial walls, floors, attics, and ceilings. It’s also frequently found in industrial structures for thermal and acoustic insulation.

Let’s dig deeper. In homes, this material often fills the spaces behind sheetrock or inside attic floors, providing warmth during cold winters and coolness during hot summers. Offices and schools rely on it not just for temperature control, but also to keep spaces quieter by absorbing sound. In industrial settings, like the facilities Hans Müller manages, fiberglass batts can wrap around tanks and pipes to cut heat loss and energy use.

Here is a breakdown of common application areas:

| Application Area | Importance | Benefits |

|---|---|---|

| Walls & Ceilings | Main source of heat loss | Saves energy, easy installation |

| Attics | Prevents rising heat loss | Keeps buildings cooler in summer |

| Floors | Reduces noise & temp loss | Warmer, quieter rooms above unheated bays |

| Tanks & Pipes | Limits energy loss | Helps prevent condensation |

Every application uses the basic principle of trapping air to slow down the movement of heat and even sound.

What are the advantages and disadvantages of fiberglass batt insulation?

Choice always brings questions. Builders want to know if fiberglass is really the best solution for their needs, or if another material could bring a better payoff.

The main advantages of fiberglass batt insulation are its low cost, easy installation, non-combustibility, and good thermal resistance. Disadvantages include its potential to cause skin irritation, lower effectiveness if not installed carefully, and poor resistance to moisture over long periods.

From my experience, fiberglass batt insulation is affordable compared to many alternatives. Installers like it because they can easily cut and place it between standard framing, and it doesn’t burn, so it adds a layer of safety. On the downside, small fibers may irritate the skin, so gloves and masks are a must during work. When this insulation is not placed tightly, air can sneak around the batts and cause drafts or cold spots. It also doesn’t handle water well; if it gets wet and stays damp, it can lose performance and even lead to mold.

Here’s a quick look at the pros and cons:

| Pros | Cons |

|---|---|

| Low cost | Can irritate skin and lungs |

| Easy to install | Less effective if installed poorly |

| Fire resistant | Loses insulation power if it’s wet |

| Available in many sizes | Not the best sound absorber in noisy areas |

How does fiberglass batt insulation compare to other types?

Contractors have lots of choices, like foam, cellulose, and mineral wool. It is easy to feel unsure about the differences.

Fiberglass batt insulation is generally less expensive than foam and mineral wool, and quicker to install than most loose-fill products. However, it has a lower R-value per inch than some alternatives and does not resist water as well as closed-cell foams.

Take foam insulation. It seals air leaks extremely well and has a higher R-value, but it costs more and needs specialized installers. Mineral wool also resists fire and water better than fiberglass and has higher soundproofing, but it’s heavier, which may increase costs. Cellulose, made from recycled paper, offers good performance and sound control, yet it can settle over time, leaving gaps if not dense packed.

Here’s a table for easy comparison:

| Material | R-Value/in | Cost | Water Resistance | Fire Resistance | Eco-Friendly |

|---|---|---|---|---|---|

| Fiberglass Batts | 2.9-3.8 | Low | Medium | High | Medium |

| Mineral Wool | 3.0-4.2 | Medium | High | High | Medium |

| Spray Foam | 5.0-7.0 | High | Very High | Medium | Low |

| Cellulose | 3.2-3.8 | Medium | Low | Low | High |

Choosing the right insulation is really about trade-offs: money, time, performance, and special project needs. I always recommend looking at the big picture for each project.

Conclusion

Fiberglass batt insulation is a trusted, cost-effective solution for many buildings. It works best when installed properly and is chosen to match the project’s specific needs.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions