What Is Faced Rockwool and Why Should You Consider Using It?

Moisture, heat and fire are relentless enemies of your building’s comfort and safety.

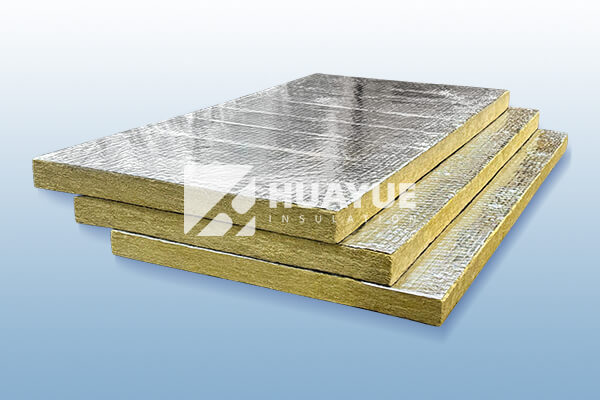

Faced rockwool insulation is mineral wool with a protective facing, such as foil or kraft paper, which improves moisture resistance, increases durability, and simplifies installation.

Choosing the wrong material—or no facing at all—can create hidden risks inside your walls and ceilings. I have seen facilities suffer from mold, condensation, and even code violations. Let’s see why the right facing can safeguard your investment.

What Types of Facings Are Available for Rockwool Insulation?

A single tiny layer can make a world of difference.

The most common facings for rockwool are aluminum foil, glass fiber tissue, and kraft paper. Each has unique properties suited for specific applications like moisture control, fire protection, or easy labeling and cutting.

You will see these typical uses:

| Facing Type | Strength | Best Use |

|---|---|---|

| Aluminum Foil | Moisture/fire barrier | Pipes, ducts, industrial |

| Glass Fiber Tissue | Robust, extra adhesion | Ceilings, external walls |

| Kraft Paper | Vapor barrier | Residential walls, attics |

Aluminum foil stops water vapor on cold pipes or tanks. Kraft paper is simple but good for dry spaces. Glass tissue adds toughness. In one project, using foil-faced rockwool stopped water from entering a cryogenic tank, preventing costly corrosion.

Why Is Faced Rockwool Better for Moisture and Fire Protection?

Leaving mineral wool exposed can be risky, even when it resists fire and moisture by itself.

Facings act as a second layer of defense. Foil and glass fabric prevent water and vapor from touching the mineral wool, reducing the chance of corrosion under insulation or insulation breakdown. Many facings are also fire-rated, adding extra minutes to survive a fire.

A client once thought plain mineral wool would suffice for an offshore tank, but salt air began attacking unprotected spots. Swapping to foil-faced insulation solved the rust problem and met insurance requirements for fire safety.

How Does Faced Insulation Improve Installation and Maintenance?

Teams often ignore this step but regret it later.

Faced rockwool makes installation easier and faster. The facing holds the slab or roll together, stops fibers from escaping, and can be stapled, taped, or glued for a tighter finish. It is also easier to trim without loose dust.

Maintenance is easier. The facing often serves as a “wear layer,” allowing surface cleaning and quick inspection without removing the insulation. It can also be marked with codes or batch numbers for easy traceability.

My partners in plant maintenance tell me it’s easier to spot water leaks on foil-faced insulation than bare mineral wool. This reduces downtime and helps stay ahead of small problems.

Are There Downsides or Limitations to Faced Rockwool?

No product is perfect for every job.

Faced rockwool may cost more, is slightly heavier, and sometimes can’t be used on surfaces over 250°C (the facing can degrade). Some facings aren’t rated for outdoor use and may break down in strong sunlight or extreme weather.

I always tell clients to check if their application involves high heat, strong chemicals, or UV exposure—plain mineral wool or a special facing may be necessary.

How Should You Select the Right Faced Rockwool Product?

Picking the right product means looking at your project, not just the price list.

Ask yourself:

- Will there be high humidity?

- Is fire resistance critical?

- What is the max. temperature?

- Will the insulation be visible or subject to damage?

Ask your supplier about options—there are custom facings for everything from freezer rooms to chemical reactors. Specify your needs early to prevent installing the wrong product and facing costly change orders.

Conclusion

Faced rockwool gives you extra protection and peace of mind, saving on repairs and keeping your building safe and dry.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions