Types of Mineral Wool Insulation: Which Is Right For Your Project?

Sometimes choosing the best insulation can feel overwhelming. Poor decisions may lead to energy loss, safety hazards, and high maintenance costs.

The different types of mineral wool insulation include rock wool, slag wool, and glass wool. Each has unique properties for thermal resistance, fire safety, and moisture control.

When I began my work in the insulation industry, I found these choices confusing. Finding the right type for a specific application was hard. If you want to keep your project efficient and safe, you need to know the differences, benefits, and drawbacks. Let’s break down the key questions about mineral wool insulation.

What are the different types of mineral wool?

Picking the wrong insulation type can waste money and cause future headaches.

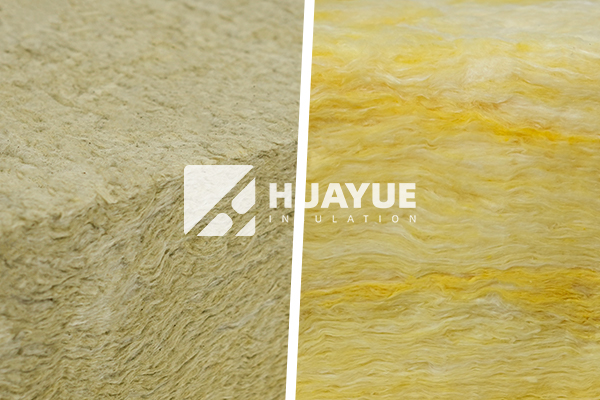

There are three primary types of mineral wool insulation: rock wool, slag wool, and glass wool. Rock wool is made from natural basalt rock, slag wool is produced from blast furnace slag, and glass wool comes from recycled glass.

Let’s drill down. Rock wool is made by melting natural basalt rock in a furnace, then spinning it into fibers. This gives it strong fire resistance and thermal insulation. Slag wool uses blast furnace slag—a byproduct from steel production. It offers good fire resistance and is often used in industrial applications, like tanks and pipes. Glass wool takes recycled glass and sand, heats them, and spins fibers. It’s lighter, easier to install, and great for residential and commercial buildings.

Here’s a summary table:

| Type | Source Materials | Key Properties | Main Uses |

|---|---|---|---|

| Rock Wool | Basalt rock | High fire, acoustic, water durability | Industrial tanks, commercial walls |

| Slag Wool | Blast furnace slag | Good fire resistance, cost-effective | Industrial insulation, pipes |

| Glass Wool | Recycled glass & sand | Lightweight, easy install, good R-value | Roofs, wall cavities |

After using all three, I see each has its strengths. Rock wool performs in harsh conditions. Glass wool is lighter and less dense. The key is matching the product to your needs.

What is the difference between rockwool and mineral wool?

Confusion about “rock wool” and “mineral wool” often leads to mistakes in the field.

Rock wool is a type of mineral wool made exclusively from basalt rock, while mineral wool is a broader category that includes rock wool and slag wool, each with different raw materials.

Mineral wool is the big umbrella. It includes products made from either rock or slag. Rock wool is the most common form of mineral wool in many countries. It always uses volcanic rock as the base, giving it a naturally high melting point and great fire performance. Slag wool, by contrast, uses steel industry slag, which makes it slightly less dense but still fire resistant.

Here’s how they break down:

| Product | Raw Ingredient | Typical Density | Main Feature |

|---|---|---|---|

| Mineral Wool | Rock/Slag | Medium-High | General insulation |

| Rock Wool | Basalt Rock | Highest | Fire, acoustic, mechanical strength |

In my projects, I use “mineral wool” to mean both, but specifying “rock wool” always means the product with the best temperature and fire resistance.

What is the best mineral wool insulation?

So many ads make every brand sound like “the best,” but getting it wrong can be costly.

The best mineral wool insulation depends on your specific needs, but when performance matters most, rock wool is top for fire, water resistance, and strength. Glass wool is preferred for lighter, more flexible applications.

Best can mean many things. Do you want fire resistance? Go with rock wool. Need lightweight, easy installation? Choose glass wool. On a tight budget with lots of industrial piping? Slag wool could be your answer. For cryogenic tanks and severe environments, I always recommend rock wool, especially for customers like Hans who care about lifetime durability and safety compliance.

Let’s compare the options:

| Application | Best Type | Why? |

|---|---|---|

| Industrial Tanks | Rock wool | Maximum fire, water resistance |

| Residential Walls | Glass wool | Good R-value, light weight |

| Piping | Slag wool | Cost-effective, industrial use |

After 20 years in insulation, my advice: Focus on your project’s most pressing needs, then match the product properties to that requirement.

What is the downside of rockwool?

Sometimes the strongest insulation is not always the best choice.

The main downsides of rock wool are higher cost, increased weight, and the need for protective wear during handling since the fibers can cause skin irritation.

Rock wool’s strengths—high density and performance—bring some challenges. It’s heavier than glass wool, which increases transport and handling costs. When I first installed rock wool, I learned to wear gloves and long sleeves. Its fibers are sharp and itchy. Additionally, rock wool can cost more per square meter. If your application doesn’t need top-level fire protection or mechanical durability, the expense may not be justified.

Here’s a table of downsides:

| Downside | Cause | Impact |

|---|---|---|

| Itchiness | Fiber texture | Protective gear needed |

| Weight | High density | Tougher to move/install |

| Price | Material/process | Higher project cost |

For Hans and his team, I always advise them to weigh these points against the mission-critical features they need.

Will mice nest in rockwool insulation?

Nobody wants unwanted guests in their insulation. The wrong choice can invite big problems.

Mice are rarely attracted to rock wool insulation, as it is made of inorganic materials that do not provide a food source or comfortable nesting spot.

Many customers have this concern. In my experience, rock wool is not inviting to rodents because the fibers are tough and inorganic. Mice seek softer, organic insulation for nesting—like cellulose. Glass wool is slightly more prone than rock wool, but still not attractive to mice. In over 100 customer projects, I have yet to see a rodent infestation in properly installed rock wool insulation.

Here’s a simple breakdown:

| Insulation Type | Attracts Mice? | Why? |

|---|---|---|

| Rock wool | No | Inorganic, coarse fibers |

| Glass wool | Rarely | Slightly softer, still lacks food |

| Cellulose | Yes | Organic, soft, retains warmth |

Following sound installation practices and sealing all gaps will offer even better rodent resistance.

Conclusion

Different mineral wool insulation types offer unique benefits and trade-offs. Choose the right one for fire safety, performance, and budget needs—especially for demanding projects like industrial tanks.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions