Thickness of Mineral Wool Insulation: What Should You Really Know?

Many people worry about using the wrong insulation thickness and losing money or putting safety at risk. I know how these choices can make or break a project.

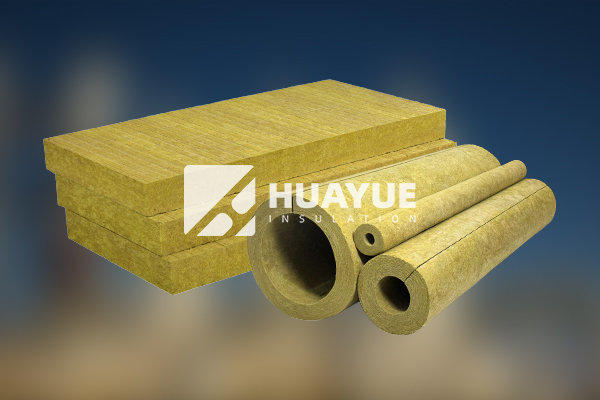

The standard thickness of mineral wool, especially ROCK WOOL boards, usually ranges from 40mm to 150mm. Custom orders can go as thin as 30mm. Insulation thickness for pipes can reach 30cm, while blankets generally offer 5cm to 15cm thickness.

There are so many products and numbers on every datasheet. Sometimes it feels overwhelming to choose the right thickness for your project. Let’s look closer at what is standard, what influences thermal efficiency, and what options are available.

What is the standard thickness of ROCK WOOL?

There is often confusion over what counts as a “standard” for ROCK WOOL thickness. This keeps many engineers unsure if they are using enough or paying for too much.

The standard thickness for ROCK WOOL insulation boards usually falls between 40mm and 150mm for most building and industrial uses. For some special needs, custom shapes as thin as 30mm can be made by manufacturers like us.

When I first started working in this industry, I saw containers packed with boards of all different thicknesses. The truth is, the “standard” thickness depends on both market demand and application. In warehousing, most stocked boards are 40mm, 50mm, 75mm, 100mm, 120mm, and 150mm thick. In industrial projects—such as insulating chemical tanks or power station pipes—engineers often order thicker slabs, up to 150mm or even higher, for better thermal performance or fire rating.

For round pipe insulation, the insulation thickness goes from 5cm up to 30cm, especially for large-diameter tanks or cryogenic needs. If someone asks for a special application, like extremely thin panels (30mm), we can produce those, though they are not a warehouse staple. With blankets or rolls, the most usual thicknesses are 5cm, 7.5cm, 10cm, and 15cm. In summary, “standard” is about matching need with what is most practical to supply. Most projects, however, select a thickness between 40 and 100mm for effective insulation and price.

| Product Type | Common Thickness Options | Special Orders Possible? |

|---|---|---|

| Board/Slab | 40mm, 50mm, 75mm, 100mm, 120mm, 150mm | Yes, >30mm possible |

| Pipe Section | 50mm – 300mm | Rare, but possible |

| Blanket/Roll | 50mm, 75mm, 100mm, 150mm | Yes, by request |

What is the R-value of 6 inches of ROCK WOOL?

Some people choose mineral wool insulation and expect it to perform like all brands and thicknesses are the same. The R-value, however, changes with material and depth.

The R-value of 6 inches (about 150mm) of ROCK WOOL is typically around R-23 to R-25, depending on density and specific product formulation.

To explain this for my customers in Europe and the USA: “R-value” tells us how well the insulation stops heat flow. ROCK WOOL and other types of mineral wool work because of their small air pockets and non-combustible fibers, forming a barrier. For every inch of ROCK WOOL insulation, the R-value is usually between 3.7 and 4.2. So, 6 inches will reach in the R-23–R-25 range. The true number can depend on product density. Higher density usually blocks heat better but costs more.

I remember a tank upgrade job we did last year. The client wanted a minimum R-20 performance. We offered 120mm thickness at high density, but for extra safety and life span, we finally switched to 150mm. This pushed the R-value past 24 and met every regulation the client faced. The message here is: check the product datasheet from your supplier and verify the density if possible. R-value is important when calculating energy savings over the lifetime of your tank or building.

| Thickness (mm) | Thickness (inches) | Typical R-Value (per thickness) |

|---|---|---|

| 25 | 1 | 3.7–4.2 |

| 50 | 2 | 7.5–8.4 |

| 100 | 4 | 15–17 |

| 150 | 6 | 23–25 |

What is the difference between ROCK WOOL and mineral wool?

Sometimes, customers ask me if ROCK WOOL and mineral wool are different products, or just different names for the same thing. This can make specifications confusing.

ROCK WOOL is a type of mineral wool. “Mineral wool” is a broad term that includes ROCK WOOL (made from basalt rock), glass wool (from glass), and slag wool (from blast furnace slag).

The confusion can lead to the wrong selection for your application, or worse, failing to meet a fire code or safety standard. Mineral wool is the family; ROCK WOOL is one member of that family. Rock wool is made by melting natural basalt and spinning it into fibers, while glass wool comes from melted glass, and slag wool uses furnace slag. All share good fire resistance and thermal efficiency.

| Type | Main Raw Material | Main Use | Common Properties |

|---|---|---|---|

| ROCK WOOL | Basalt/volcanic rock | building, tanks, piping | non-combustible, water-resistant |

| Glass Wool | Glass | commercial buildings, homes | lightweight, fire-resistant |

| Slag Wool | Furnace slag | industrial insulation | cost-effective, non-combustible |

For example, when working with sensitive chemical tanks, I always prefer ROCK WOOL for its fire rating and resistance to water absorption, compared to glass wool. Each product has its place, but ROCK WOOL stands out for heavy-duty, fire-critical, and moisture-exposed applications.

What thicknesses does ROCK WOOL insulation come in?

Many engineers I meet on-site want to know how flexible the thickness range really is. This helps them design better and save costs.

ROCK WOOL insulation is available in board, pipe, and blanket forms. Board thickness is usually 40mm to 150mm, pipe sections from 50mm to 300mm, and rolls from 50mm to 150mm.

When a project starts, my clients often ask: what if standard sizes do not fit our wall or tank design? The good news is, for boards, we supply most jobs with 40, 50, 75, 100, 120, or 150mm thicknesses. But if you need something unusual—say, 3cm for a tight panel recess or very thick pieces for a large round tank—we can make special orders in our factories.

With pipe insulation, the main need comes with very large-diameter equipment. That’s why we produce pipe sections up to 300mm wall thickness. For blankets and rolls, the common sizes are more limited. We keep 50mm to 150mm in stock but can make others with enough lead time.

If you ask me, the biggest danger is picking the wrong thickness and either underperforming or wasting money on extra material that adds little thermal value. The best way to decide is to consult your project’s thermal calculations and rely on tested datasheets from your supplier.

| Form | Normal Thickness Range | Special Thickness (custom) |

|---|---|---|

| Board/Slab | 40mm–150mm | As thin as 30mm possible |

| Pipe Section | 50mm–300mm | Sometimes more |

| Blanket/Roll | 50mm–150mm | By request |

Conclusion

ROCK WOOL insulation offers flexible thickness options to fit any project, with standard and custom possibilities to maximize thermal performance and safety at every level.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions