Rock Wool Insulation Roll: The Best Solution for Your Industrial Tanks?

Many plant engineers face issues with tank insulation failing over time—costly replacements and safety worries make a reliable, long-lasting choice crucial.

Rock wool insulation rolls offer excellent thermal performance, fire resistance, and moisture protection, making them a popular fit for industrial tank insulation that needs to last and stay safe.

If you are in charge of keeping tanks running smoothly, finding dependable insulation matters. I have spent years comparing materials, always searching for what works best for chemical and cryogenic tanks. Sometimes the smallest difference in insulation quality means big savings in maintenance and downtime. Let’s look deeper into what makes rock wool rolls special—and where their limits lie.

What are the downsides of Rock wool insulation?

Downtime from insulation problems leads to headaches and high bills. If rock wool fails, it can mean disruptions across the entire tank system.

Rock wool insulation rolls have a few weaknesses: they may shed fibers, absorb moisture if not sealed, and sometimes show reduced compression strength compared to rigid boards.

Rock wool’s natural fibers make it great for resisting fire and heat. However, loose fibers can be an issue. Fiber shedding can irritate skin and eyes during installation and maintenance. Some plant managers tell me their teams need full protection gear when cutting or installing it. There is also the risk of water absorption if the insulation gets punctured or is not sealed correctly at joints or edges. This is a concern for cryogenic tanks, where keeping a dry system matters. Another challenge—the roll format is less sturdy under compressed loads compared to rigid rock wool boards, which might be important in some maintenance or high-pressure applications. Here’s a quick breakdown:

| Issue | Explanation | Impact in Industrial Tanks |

|---|---|---|

| Fiber Shedding | Loose fibers, dust | Possible health/cleaning risks |

| Water Absorption | Poor seals, leaks | CUI risk, reduced effectiveness |

| Compression Weakness | Not rigid | Could compact, reduce insulation |

When evaluating, I compare the tank design, maintenance schedule, and environmental demands. Sometimes, rigid boards are better for high-impact zones. Rolls fit curved surfaces with fewer seams. But I always remind my team—never skip proper joint sealing and vapor barriers.

Does Rock wool come in a roll?

Trying to insulate curved tanks quickly? Many engineers wonder if rock wool is easy to install in roll form to save time.

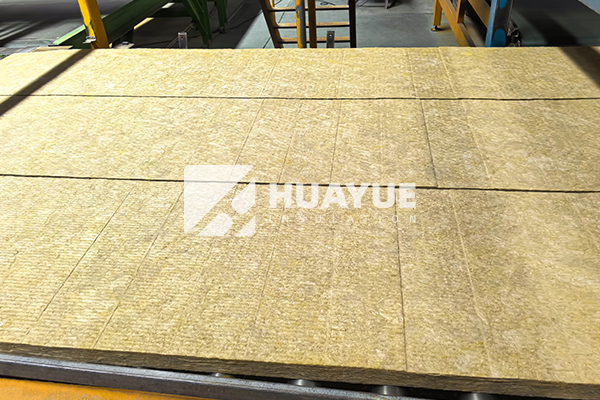

Rock wool insulation is available as both rolls and batts, with rolls being flexible enough to wrap around pipes and curved tank surfaces easily.

Rock wool rolls have a flexible structure made by spinning molten rock into thin filaments, then layering them. Rolls come in lengths up to 10 meters and standard widths to suit most pipe and tank sizes. I find rolls ideal when working on large curved tanks or long pipe runs, especially when time is tight. Unlike rigid panels, rolls allow installers to wrap surfaces with fewer seams, which means fewer points for heat or moisture to escape. Some customers ask if the roll format is as effective as batts or boards. I explain that rolls maintain the same thermal properties when installed correctly with proper support. They are suitable for rapidly covering large areas due to their flexibility and continuous length.

| Format | Typical Use | Advantages |

|---|---|---|

| Roll | Pipes, curved tanks | Easy install, fewer seams |

| Batt | Walls, flat surfaces | Pre-cut sizes, simple layering |

| Board | Heavy-duty, flat surfaces | High compression, rigid support |

In my experience, rolls are particularly helpful for tanks that don’t have perfectly flat surfaces. It saves installation time and matches the contour of the tank. I advise always checking the insulation thickness needed for the specific tank to fit the project’s fire, thermal, and moisture standards.

Do mice like Rock wool insulation?

No one wants rodents or pests inside tank insulation—problems with vermin can cause hygiene and damage risks in chemical facilities.

Rock wool insulation does not attract mice or pests. It is inorganic and offers no food source, so rodents do not usually nest in it.

Rodent damage is a problem with organic insulation materials like fiberglass or cellulose. I have seen rodent nests inside some tank insulation before, but rarely in rock wool. The structure of rock wool is dense and mineral-based, and it does not provide warmth, softness, or nutrition for pests. Many factories choose rock wool for this reason—especially where tanks are outdoors or in basements prone to mice. If installation leaves gaps between rolls or boards, however, pests may find places to hide. So, sealing and continuous coverage are important. Here’s a quick comparison:

| Insulation Type | Does it Attract Rodents? | Notes |

|---|---|---|

| Rock Wool | No | Inorganic, dense |

| Fiberglass | Sometimes | Softer, can retain warmth |

| Cellulose | Yes | Organic, food source |

Year to year, I recommend visual inspections for tank insulation, checking for gaps or signs of pest entry. When using rock wool, there is less worry about animal damage or health risks from droppings.

What is the best way to cut rock wool insulation?

Cutting rock wool incorrectly leads to wasted product, uneven coverage, and added installation time for large tanks.

The best way to cut rock wool insulation rolls is with a long, serrated insulation knife, ensuring straight edges and minimizing fiber shedding during installation.

Cutting rock wool is easy with the right tools. I always use a specialized insulation knife—long, with wide teeth—because it slices the dense fibers cleanly without crushing the roll. I keep the roll or batt compressed on a hard surface, then cut slowly in one pass to keep edges straight. This brings better joins when installing around tanks. Wearing gloves and goggles is important to prevent skin and eye irritation from loose fibers. For curved or hard-to-reach places, I sometimes measure and cut smaller sections to fit around fixtures or supports. Here is my quick guide:

| Step | Tool Required | Why it Matters |

|---|---|---|

| Measure and mark | Tape measure, pen | Ensures accuracy |

| Compress insulation | Board or hand | Prevents jagged edges |

| Cut in one pass | Serrated knife | Clean edge, less fiber release |

| Seal joints | Tape or barrier | Keeps insulation dry and smooth |

I always suggest to my team: take time to cut neatly. Proper preparation means less waste and a better, longer-lasting fit around our tanks.

Conclusion

Rock wool insulation rolls are safe, flexible, and pest-resistant, with a few weaknesses. Proper installation helps minimize issues and boosts long-term tank reliability.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions