Rock Wool Insulation for Pipes: Should You Choose It?

When temperatures drop, pipe insulation becomes critical—but what makes rock wool a contender for your pipeline protection needs?

Rock wool insulation is safe for pipes since it’s non-combustible, resists water, and maintains its thickness under compression. It’s ideal for reducing heat loss, improving energy efficiency, and preventing pipe condensation or freezing.

Pipes in chemical plants, refineries, and even residential settings face continuous threats from temperature changes, moisture, and sometimes fire risk. In my experience, rock wool insulation’s durability, water-resistance, and fire safety make it an attractive solution worth considering. If you’re exploring whether rock wool is the right fit for your pipework, let’s break down what you need to know before making a decision.

Can you put ROCK WOOL insulation around pipes?

Protecting pipes from temperature loss and damage is essential for safety and savings. But can rock wool really be used for pipelines?

Yes, you can use rock wool insulation for both hot and cold pipes. It can withstand high temperatures, is flexible for fitting around different pipe sizes, and helps block noise as well as thermal transfer.

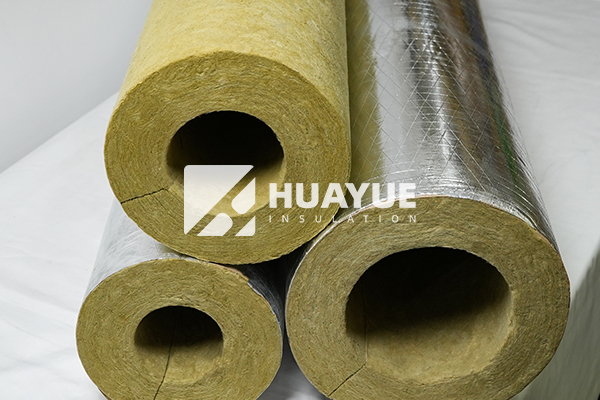

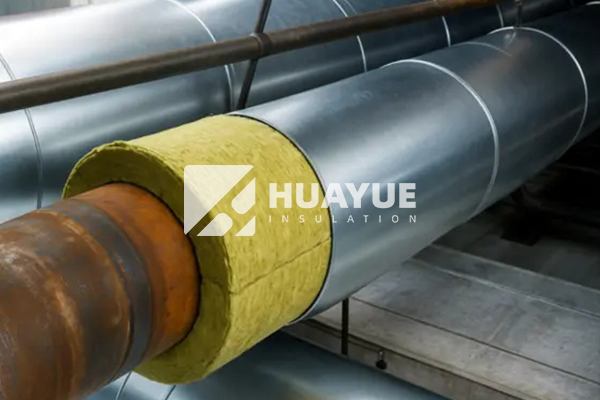

Rock wool works best on pipes due to some key properties. I often remind customers that its fiber structure traps air so heat loss slows down. Since it does not absorb water, it prevents corrosion under insulation (CUI). This is vital in facilities like Hans’s, where water and chemicals are present. Installing rock wool is easy when cut-to-size preformed pipe sections are available. These sections tightly fit the pipe’s diameter and provide even coverage, making maintenance a breeze. For bends or joints, flexible mats work well. In my professional experience, preformed shells are preferable over sheet wrap for ease and speed. After installation, an aluminum cladding or PVC jacket protects against physical damage and weather. This system works for both steam lines in power plants and domestic hot and cold water pipes. Pipe channels aboveground with heat tracing also benefit from rock wool’s insulation. Its natural composition means it does not burn or release toxic fumes, which keeps facilities safe. Always make sure the rock wool insulation matches your pipe’s temperature range and size for ideal results.

Common Applications of Rock Wool Pipe Insulation

| Application Type | Benefits | Typical Installation |

|---|---|---|

| Hot Water & Steam Pipes | Energy retention, burn protection | Preformed sections |

| Cold Water Lines | Fights condensation, prevents freezing | Flexible mats |

| Industrial Process Pipes | CUI prevention, fire safety | Shell sections |

What type of insulation is best for pipes?

Choosing the right insulation depends on temperature, moisture, and safety. Which insulation type fits most needs for pipes?

The best pipe insulation balances heat retention, fire resistance, moisture resistance, and ease of installation. Rock wool stands out for its natural fire safety and dimensional stability, especially in high-temperature and industrial environments.

A common debate in my industry is rock wool versus alternatives like fiberglass or rubber foam. Each material has its place. Rock wool resists fire, which is vital in chemical plants and high-temperature locations. It also stays rigid when pipes get hot, so insulation won’t slump or create gaps. Fiberglass is less expensive and insulates well but lacks the same level of fire resistance. Rubber foam works better in extreme cold since it’s flexible and stops condensation, but it can’t handle high-heat pipes. As someone who’s helped outfit pipes in different climates, I believe rock wool offers the best protection where safety and durability are non-negotiable. When water ingress or pipe sweating is a problem, always choose a closed-cell solution or add a vapor barrier. Sometimes, combining materials achieves the best result. For most industrial needs, rock wool’s core strength is its balance of safety, performance, and peace of mind.

Comparison Table: Common Pipe Insulation Materials

| Material | Temp. Range | Fire Safety | Water Resistance | Use Case Example |

|---|---|---|---|---|

| Rock Wool | -200°C to +650°C | Will not ignite | Does not absorb | Steam, chemical plants |

| Fiberglass | -50°C to +250°C | Burns slowly | Can absorb | Hot water lines |

| Rubber Foam | -50°C to +105°C | Will burn | Closed cell | Chilled water pipes |

What are the disadvantages of ROCK WOOL?

Everything has trade-offs. What should you watch out for when using rock wool on pipes?

Rock wool insulation is tough and fire-safe, but it sheds fibers during installation. It can irritate skin and lungs without protective gear, and it usually costs more than fiberglass or foam.

When I first started using rock wool, I underestimated how tricky the fibers could be. Wearing gloves, sleeves, and a dust mask during installation became a non-negotiable rule. After mounting the insulation, a wipe-down of the workspace kept stray fibers at bay. The price is another factor, as some alternatives come cheaper upfront, but often miss rock wool’s safety and durability advantages. Rock wool remains stable and retains its R-value over many years, even where vibration or heat cycling would collapse other materials. However, it does need protection from mechanical abuse—a tough outer jacket or cladding keeps the insulation performing at its best. I’ve also observed that in very cold environments with high humidity, adding a vapor barrier is a must to prevent surface ice. So, while the cons are few, taking care helps maximize the return on investment.

Pros and Cons of Rock Wool Insulation

| Pros | Cons |

|---|---|

| Fireproof | Can irritate skin, lungs |

| Good thermal & acoustic ins. | More expensive than fiberglass/foam |

| Does not absorb water | Requires cladding for protection |

| Keeps shape under pressure | May need vapor barrier in cold spots |

How thick is ROCK WOOL pipework insulation?

Getting the right insulation thickness means safety, efficiency, and cost control. How thick should rock wool be for pipes?

Typical rock wool insulation thickness for pipes ranges from 25mm to 100mm, with thicker insulation used for higher temperatures, bigger pipes, or energy savings. Always match the thickness to the pipe size and service temperature.

Pipe insulation isn’t one-size-fits-all. In my work with both small and large diameter pipes, I consult standards like EN 13468 or ASTM C585 for accurate guidance. Steam or hot water pipes often need thicker insulation, especially in cold climates, to fight heat loss. For example, small hot water lines in a facility might need 40mm rock wool, while main steam trunks might require 60–100mm for optimal results. Cold and cryogenic pipes need not just insulation but also vapor barriers to prevent icing. Site requirements like available space, support brackets, and cladding must be checked since thick insulation adds bulk and weight. I always recommend a survey, so you’re not guessing. For Hans and others, matching insulation to pipe specification and operating environment maximizes both performance and budget.

Rock Wool Pipe Insulation Thickness Reference

| Pipe Temperature | Pipe Diameter | Min. Thickness (mm) |

|---|---|---|

| ≤ 100°C | 15–50 mm | 30–40 |

| 100–250°C | 25–100 mm | 50–75 |

| > 250°C | 50–500 mm | 75–100 |

Conclusion

Rock wool insulation offers reliable, fire-safe, and efficient protection for pipes, provided you address installation safety and choose the right thickness for your application.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions