Rock Wool Insulation 2x6: Is It the Best Choice for Your Walls?

Many homeowners and engineers need to choose the right insulation for their 2×6 walls. They often worry about R-values, cost, safety, and long-term performance.

A 2×6 wall insulated with rock wool batts typically reaches an R-value between R-23 and R-24. This gives effective thermal protection, fire resistance, and helps with soundproofing compared to most other common materials.

When you need to select insulation for a 2×6 wall, the choice can feel complicated. You have to think about energy savings, fire protection, moisture resistance, and building codes. I have worked with hundreds of engineers and builders who want solutions that last. Let me walk you through the most important things to consider when evaluating 2×6 insulation options.

What is the R-value of Rock Wool for a 2×6 wall?

Choosing insulation for your walls can be hard. You hear many claims about energy savings and fire protection. But what really matters is the R-value.

The R-value of rock wool batts for a 2×6 wall is usually R-23 or R-24. This level is high enough for most climates and code requirements.

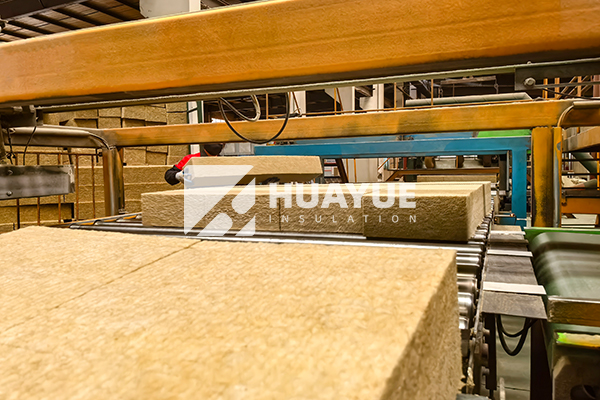

I remember the first time I tried rock wool in a 2×6 wall assembly. I was building an addition, and I needed insulation that would meet new local energy codes without sacrificing space. Rock wool batts made for 2×6 framing are usually 5.5 inches thick. They fit snugly and fill the cavity completely.

Here is a breakdown of popular wall insulation types for 2×6 framing and their typical R-values:

| Insulation Type | Thickness | R-Value (per cavity) | Fire Resistance | Sound Dampening | Moisture Resistance |

|---|---|---|---|---|---|

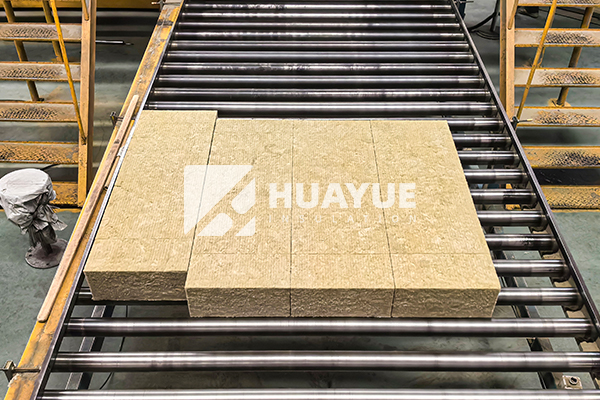

| Rock Wool (Mineral Wool) | 5.5 inch | R-23 to R-24 | Excellent | Excellent | Excellent |

| Fiberglass | 5.5 inch | R-19 to R-21 | Moderate | Good | Moderate |

| Spray Foam (Closed Cell) | ~5 inch | R-30 to R-35 | Excellent | Good | Excellent |

You can see that rock wool stands out. Its fire and soundproofing properties make it great for industrial tanks, mechanical rooms, or noisy living areas. Rock wool also does not trap moisture. That makes mold and corrosion under insulation (CUI) less likely. For engineers like Hans, the advantage is clear: rock wool aligns with practical performance and long-term reliability.

What is the best insulation for a 2×6 wall?

People often get overwhelmed by choices. Many want the “best” insulation but do not know how each type stacks up for 2×6 framing.

Rock wool is often the best insulation for a 2×6 wall due to its balance of high R-value, fire resistance, soundproofing, and moisture proofing. It fits standard 2×6 wall cavities perfectly.

I have toured many production facilities and studied wall assemblies for years. When looking at performance, you want to focus on a few factors. These include: R-value, long-term durability, resistance to mold, and how insulation handles fire risk.

Here is what you need to know:

- Rock wool stays stable over time. Fiberglass can slump or settle, leaving gaps.

- Unlike spray foam, rock wool does not release fumes during installation.

- Mineral wool does not burn, and actually slows fire spread in walls.

- Moisture does not damage rock wool. It dries out and keeps its integrity.

- If you need to hit an R-value of 23-24, rock wool is tailored to fit 2×6 wood or steel studs.

- Unlike foam, it is easy to cut and retrofit.

For those working on chemical plants or energy-efficient homes, consistency and code compliance matter. Engineers often specify rock wool for walls near mechanical rooms, kitchens, or storage tanks because of its non-combustible and non-absorbent nature. This is why, based on direct project experience, I trust rock wool as the "best all-around" pick for 2×6 wall systems.

What R-value goes in 2×6 walls?

When you build or upgrade a home or industrial site, codes and comfort depend on having enough insulation. Many people are unsure what the minimum R-value should be for a 2×6 wall.

Most building codes recommend an R-value between R-21 and R-24 for 2×6 stud walls, depending on climate zone and application.

Knowing what R-value you need is essential. I do a lot of work with buildings in both cold and mild climates. For most places in North America and Europe, R-23 is required or preferred. Some very cold zones suggest aiming for R-24 or higher.

Here’s a simple reference to help you match insulation to 2×6 wall requirements:

| Climate Zone | Code Minimum R-value | Preferred R-value | Suitable Insulation Options |

|---|---|---|---|

| Mild (Zone 3-4) | R-19 | R-21 | Fiberglass, Rock Wool |

| Cold (Zone 5+) | R-21 | R-23-24 | Rock Wool, Spray Foam |

| Severe/Industrial | R-23 | R-23+ | Rock Wool, Spray Foam |

If you need to meet strict codes or want better comfort and efficiency, choose the highest-rated batt that fits a 2×6 wall cavity. For critical tanks or plant rooms, go with rock wool. It is easy to install, meets most safety standards, and serves well for decades.

What is the R-value of 6 inch Rock wool?

It is common to find odd wall dimensions and wonder about rock wool’s performance at 6 inches thick versus standard batts for 2×6 walls.

The R-value of 6 inch thick rock wool is typically R-24 to R-25. This gives slightly better thermal performance compared to the standard 5.5 inch (2×6) batt.

If you have a wall or tank shell that allows for a full 6 inches of insulation, you get a bit more protection. I once worked with a team retrofitting a high-humidity mechanical room. We switched from fiberglass to 6 inch rock wool, and the difference was clear. Not only was the space quieter, but equipment ran cooler and required less maintenance.

Rock wool is dense and will not slump. Even at full thickness, it retains its sound and fire-blocking properties. Condensation control improves, which is a benefit for engineers who worry about CUI or mold. If you want to get the maximum out of your wall, and you can fit 6 inches, go with the thickest rock wool batt offered by the manufacturer.

Conclusion

Rock wool is one of the best choices for 2×6 wall insulation, offering high R-value, non-combustibility, sound control, and long-term durability.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions