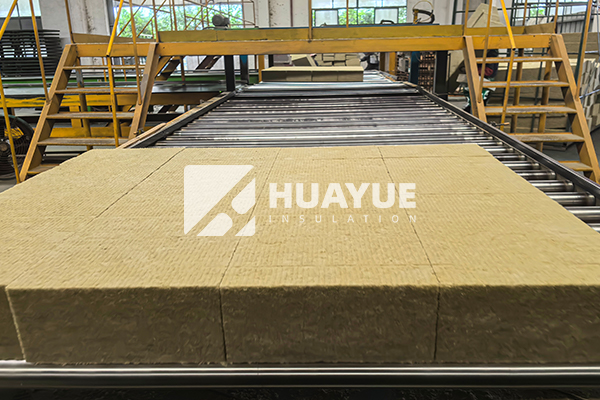

R15 Rock Wool: What Should You Really Know?

Most people do not realize how different R15 rock wool can make their tanks or buildings. Not understanding R-values leads to wasted energy and higher costs.

R15 rock wool refers to an insulation material with a thermal resistance rating of R15, designed mainly for walls, ceilings, and tanks to enhance energy savings and thermal performance.

Many engineers and facility managers overlook the variety of options in insulation materials. Choosing the right insulation directly affects lifetime costs, energy efficiency, and maintenance. This article will answer your top questions about R15 rock wool, help you understand the most important specs, and help you make the best decision for your needs.

What size is Rock wool R15?

Do not confuse the R15 rating with the actual size of the rock wool. Many people buy the wrong thickness or dimensions and end up with poor insulation.

R15 rock wool insulation normally comes in batts or rolls with a thickness close to 3.5 inches (89mm), designed to fit standard wall studs or tank panels.

The actual size of R15 rock wool can change depending on the manufacturer and the intended application. Standard industrial use, such as insulating tanks, usually uses batts with a width that matches typical framing systems—common widths are 16 inches (406mm) or 24 inches (610mm). The length of each batt can be several feet, often 48 inches (1219mm) or even longer for easier handling. When working with cryogenic tanks, the main concern is making sure the insulation has no gaps, and the batts are cut to fit around corners, brackets, and pipework. The thickness of about 3.5 inches gives the R15 rating, but if you need more resistance, you may need double layers. Always check the technical datasheet from your supplier, as custom sizes are possible for tanks or walls. Choose sizes that make the installation tighter and limit thermal bridging.

| Common R15 Rock Wool Sizes | Inches (in) | Millimeters (mm) |

|---|---|---|

| Thickness | 3.5 | 89 |

| Width | 16 / 24 | 406 / 610 |

| Length (Per Batt) | 48+ | 1219+ |

What does R15 mean for insulation?

People often hear the term “R15” but may not know what it stands for. Guessing can mean your project does not meet energy standards, leading to penalties and higher power bills.

The R15 value measures the thermal resistance of the insulation. It shows the material’s ability to resist heat flow and keep energy inside or outside as needed.

Diving in, the R-value is a standardized measure used globally. It adds up all the ways heat travels through a material—by conduction, convection, and radiation—and averages them out. For R15 rock wool, it means the material can slow down how much heat transfers at a rate that meets or beats local building codes for walls and tanks. The “R” stands for resistance. The “15” is a number with no units—but for context, higher numbers mean better insulation. If you install R15 rock wool in your chemical tank facility, you get less thermal loss in winter or heat gain in summer. Less temperature swing helps process stability and saves energy. However, what is good enough in Germany might not meet regulations in Norway, so always check your country’s code before installation. Good by itself, R15 can be layered with other products to get higher total resistance values, especially for extreme cold like in cryogenic service.

Understanding R-Value Comparison

| Application | Minimum Recommended R-Value | R15 Performance |

|---|---|---|

| Interior Walls | R13 – R15 | Meets or exceeds |

| Tank Shell Insulation | R10+ | Surpasses minimums |

| Attic Floor | R30+ | May need double layer |

What is the R rating of Rock wool?

A lot of experts rely on the label “rock wool” and forget that it can come in many different R ratings. Not checking this can result in insulation that does not meet requirements.

Rock wool batts can range from R11 to up to R30 or higher, depending on their thickness and density. R15 is one of the most popular for standard wall and tank applications.

The R rating, which stands for resistance, is set by the thickness and density of the rock wool. Thicker and denser batts have higher R-values. For example, a 2-inch (51mm) rock wool batt could have an R8 value, while a 5.5-inch (140mm) batt could hit R23 or R24. In practice, manufacturers design batts to match standard building codes: R13, R15, R19, or R21 for walls. In heavy industry, like chemical tanks, engineers must calculate the right thickness based on required temperature drop, not just the R number on the package. Always match the R rating to the use case, as over-insulating adds cost with little benefit, and under-insulating risks energy waste and faster system breakdown.

Sample R Ratings of Rock Wool by Thickness

| Thickness (inches) | R Value |

|---|---|

| 2 | R8 |

| 3.5 | R15 |

| 5.5 | R23 |

Is the Rock wool R15 soundproof?

Some people think all insulation is the same for sound, but that is not true. Choosing the wrong product might not block noise at all.

R15 rock wool is not completely soundproof, but it does give a high level of sound absorption. This makes it much better than many fiberglass options in blocking noise between spaces or tank walls.

Rock wool has a fiber structure that traps sounds and reduces vibrations traveling through walls or panels. When used in chemical plants, this insulation not only stops thermal loss but can also dampen the sound from pumps, compressors, or heavy machinery. It is a common choice for recording studios or conference rooms for the same reason. The key measurement is the Noise Reduction Coefficient (NRC), which shows how much sound energy is absorbed. Standard R15 rock wool often has NRC values from 0.9 to 1.0, which means it absorbs 90-100% of sound it contacts. However, it is not the same as full “soundproofing,” as direct vibrations, structure-borne sound, or air gaps can still pass noise through. For tanks, combining R15 rock wool with thicker steel walls or sound-damping mats gives better results if noise control is critical.

Comparing NRC Ratings of Common Wall Insulations

| Material | NRC Value | Effectiveness |

|---|---|---|

| Fiberglass Batts | 0.7 | Good |

| R15 Rock Wool | 0.95 | Very high |

| Solid Concrete | 0.4 | Low |

Is ROCK WOOL safe for lungs?

People worry about working with rock wool and possible lung hazards. Seeing the fibers, you might expect breathing them in could cause trouble.

Modern R15 rock wool is considered safe for lungs if installation follows normal protective steps, such as using masks and gloves.

Rock wool is made by spinning molten basalt or slag into fine fibers. These fibers are not the same as asbestos, which is known to be very dangerous for lungs. Most health authorities, including OSHA and the World Health Organization, say rock wool does not pose a long-term risk of lung disease. During installation, fibers may be released, and if you breathe these in, you might experience minor, temporary irritation of the nose, throat, or lungs—about the same as household dust. Wearing a standard P2 or N95 mask is enough to stop this. Once installed and covered by tank jackets, wallboard, or vapor barriers, the risk drops to almost zero, as the material becomes sealed away. Still, always follow local safety rules during handling, and avoid cutting batts without ventilation or dust extraction. For engineers like me, the peace of mind comes from strict manufacturing controls and product certifications, which ensure the lowest fiber release possible.

Rock Wool Safety at a Glance

| Hazard Type | Risk Level | Mitigation Steps |

|---|---|---|

| Fiber Inhalation | Low (with PPE) | Use dust mask, gloves |

| Long-Term Lung Impact | None proven | Certified safe by authorities |

| Skin & Eye Irritation | Possible short-term | Wear protective clothing |

Conclusion

R15 rock wool gives dependable energy savings, sound protection, and trusted safety for industrial and building projects, making it a smart choice for insulation needs.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions