Is Fiberglass Insulation Flammable?

Struggling with insulation choices and worried about fire safety? You’re not alone. The fear of a fire hazard in your walls is a major concern for any property owner.

Fiberglass insulation itself is not flammable. The glass fibers are naturally non-combustible and can withstand high temperatures. However, the facing or backing on some fiberglass batts, often made of paper or foil, can be flammable and contribute to the spread of fire if not properly treated.

Making the right choice in insulation is about more than just temperature control; it’s about securing your peace of mind. As a company that has been dealing with insulation since 1998, we’ve seen it all. We understand that the details matter, especially when it comes to the safety of your home or project. Let’s walk through what makes fiberglass a trusted option for fire resistance and how to ensure you’re using it as safely as possible.

How Does Fiberglass Insulation React to Fire?

Wondering what actually happens to fiberglass when it’s exposed to flames? It’s a common question we get from clients who are trying to make the safest choice for their buildings.

When exposed to fire, the glass fibers in fiberglass insulation do not burn; instead, they melt at extremely high temperatures, typically around 1,000°F (or about 540°C). This inherent characteristic of glass makes the core material of the insulation non-combustible and helps to slow the spread of flames.

The core material of fiberglass insulation is spun glass, which is inherently resistant to fire. Think about what happens when you heat glass; it glows and eventually melts, but it doesn’t burst into flames. This is exactly how the fibers in the insulation behave. They won’t act as fuel for a fire. This is a critical safety feature. However, the story doesn’t end there. Many fiberglass insulation products, especially the batts and rolls you commonly see, come with a facing. This facing is often made of kraft paper, which is a flammable material. Manufacturers treat this paper with fire retardants to slow its ignition, but it can still burn. When the facing ignites, it can contribute to the spread of fire along the surface of the insulation, even if the fiberglass itself isn’t burning. The smoke produced from the burning facing and the binding agents can also be hazardous. So, while the insulation’s core is non-combustible, the complete product’s reaction to fire depends heavily on its facing material.

Is Fiberglass Insulation Considered Fireproof or Fire-Resistant?

Are you confused about whether fiberglass is truly fireproof? The terms "fireproof" and "fire-resistant" are often used interchangeably, but they mean very different things in the world of building materials.

Fiberglass insulation is classified as fire-resistant, not fireproof. This means it can resist heat and slow the spread of a fire for a specific period, but it is not impervious to fire. No building material is truly "fireproof" as everything will fail at a high enough temperature.

%[A firefighter inspecting insulation after a fire](

Understanding the Distinction

The term "fireproof" implies that a material is completely immune to the effects of fire, which is not realistic for any material. "Fire-resistant," on the other hand, is a more accurate and technical term. It means the material has been tested and rated to withstand fire for a certain amount of time, helping to contain it and provide crucial time for evacuation. Fiberglass insulation’s non-combustible nature earns it this classification. The glass fibers themselves will not ignite or serve as fuel. This property is essential for building safety, as it helps to compartmentalize a fire, preventing it from quickly moving from one room to another through the wall cavities. This resistance is a key reason why fiberglass is a popular choice in residential and commercial construction. It’s an integral part of a building’s overall fire safety system, working alongside other fire-rated materials to protect occupants and property.

What Are the Fire Ratings and Safety Standards for Fiberglass Insulation?

Trying to navigate the technical jargon of fire safety ratings? It can be confusing, but understanding these ratings is key to ensuring your building is up to code and safe.

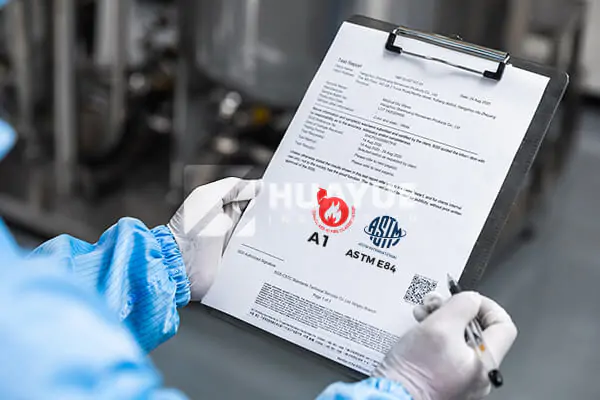

Fiberglass insulation is tested and classified according to standards like ASTM E84 and ASTM E136. These tests determine its flame spread index and smoke development index. Unfaced fiberglass insulation typically has a flame spread of 25 or less and a smoke development of 50 or less, earning it a Class A Fire Rating.

Breaking Down the Ratings

Let’s look at what these ratings actually mean for your project. The two most important tests for fire performance of insulation are ASTM E136 and ASTM E84.

-

ASTM E136 (Test Method for Behavior of Materials in a Vertical Tube Furnace at 750°C): This is the test for combustibility. Materials that pass this test, like unfaced fiberglass, are considered non-combustible. They simply won’t burn under these intense conditions.

-

ASTM E84 (Test Method for Surface Burning Characteristics of Building Materials): This test measures how quickly a fire spreads across a material’s surface (Flame Spread Index) and how much smoke it produces (Smoke-Developed Index). The results are used to assign a fire rating.

Here’s a simple table to understand the classifications:

| Class | Flame Spread Index | Smoke-Developed Index |

|---|---|---|

| A | 0-25 | 0-450 |

| B | 26-75 | 0-450 |

| C | 76-200 | 0-450 |

Unfaced fiberglass consistently achieves a Class A rating, the best possible classification. This means it contributes very little to the spread of a fire. However, the facing material is what can change the rating. Fire-retardant kraft-faced insulation also aims for a Class A rating, but it’s crucial to check the manufacturer’s specifications for the specific product you are using to ensure it meets the safety requirements for your application.

How Does Fiberglass Compare to Other Insulation Types in Fire Safety?

Choosing insulation involves weighing many factors, and fire safety is a top priority. How does standard fiberglass stack up against other popular choices like spray foam or cellulose?

Fiberglass offers excellent fire resistance due to its non-combustible nature. It generally performs better than cellulose, which is made from flammable paper, and some types of spray foam. Each material, however, has its own unique fire-related properties and treatments.

A Head-to-Head Comparison

When I consult on large industrial projects, like for my client Hans in Germany who manages chemical tank facilities, fire safety is non-negotiable. We have to look at the entire life cycle and performance of the material. Here’s a more detailed breakdown of how fiberglass compares to other common insulation types in terms of fire performance:

| Insulation Type | Base Material | Fire Safety Characteristics |

|---|---|---|

| Fiberglass | Spun Glass Fibers | Non-combustible. The core material will not burn. Faced versions can have flammable paper backing, but they are treated with fire retardants. Achieves a Class A fire rating. |

| Spray Foam | Polyurethane or Polyisocyanurate | Combustible. It is a plastic that will burn and can release toxic smoke. It must be treated with fire retardants and is required by code to be covered by a thermal barrier like drywall. |

| Cellulose | Recycled Paper/Wood Products | Combustible. The base material is highly flammable. It is heavily treated with fire retardants (like borates) to resist ignition, but it will eventually burn if the fire is hot enough. |

| Rock Wool | Volcanic Rock (Basalt) and Slag | Non-combustible. Similar to fiberglass but has a much higher melting point (around 2,000°F / 1,093°C), providing superior fire resistance. Often used in fire-stopping applications. |

| Foam Glass | Recycled Glass | Non-combustible and impermeable. It will not burn, absorb flammable liquids, or wick moisture, making it exceptionally safe, especially for industrial tanks where CUI is a risk. |

For most residential and commercial applications, fiberglass provides a very reliable level of fire safety. For high-risk industrial settings, materials like Rock Wool or Foam Glass, which we also specialize in at HUAYUE, are often specified for their superior performance at extreme temperatures.

What Are Some Tips for Improving Fire Safety With Fiberglass Insulation?

Installing insulation correctly is just as important as choosing the right material. Are there extra steps you can take to maximize the fire safety of your fiberglass insulation?

Yes, absolutely. Proper installation techniques and pairing fiberglass with other fire-rated materials are crucial. From using unfaced products where possible to ensuring a professional installation, these steps can significantly enhance the overall fire resistance of your building assembly.

Enhancing Your Fire Defenses

Over my 30+ years in the insulation industry, I’ve seen how small details in installation can make a huge difference in safety. It’s not just about stuffing batts into a wall. Here are six practical tips to ensure you get the maximum fire safety benefit from your fiberglass insulation:

- Use Unfaced Fiberglass When Possible: In areas where a vapor barrier isn’t required, or can be applied separately, use unfaced fiberglass. This completely eliminates the risk associated with flammable kraft paper facing.

- Install According to Local Building Codes: Codes exist for a reason. They mandate specific installation practices, like keeping insulation away from heat sources like recessed lighting (unless IC-rated) and flue pipes, to prevent fires. Always follow them.

- Seal Gaps and Cracks with Fire-Resistant Materials: Air gaps can allow fire to travel quickly through walls. Use fire-rated caulk or fireblocking materials to seal any penetrations and gaps around the insulation.

- Pair With Fire-Rated Drywall: Fiberglass insulation is one part of a fire-rated assembly. Covering it with a thermal barrier like 5/8" Type X drywall is required by code and dramatically increases the time a wall can withstand a fire.

- Inspect Regularly for Damage or Moisture: Damaged or compressed insulation is less effective. Moisture can also degrade the fire-retardant treatment on the facing. Periodically check your insulation in accessible areas like attics and crawl spaces.

- Hire a Licensed Professional for Installation: A professional installer understands the codes and best practices. They will ensure the insulation is fitted properly without gaps and that all safety precautions are taken, giving you a safer final result.

Conclusion

In summary, fiberglass insulation is a reliable, non-combustible material. Its fire-resistant properties make it a safe and widely used choice, provided it is installed correctly and its facing is handled properly.

As a global supplier with roots dating back to 1998, HUAYUE Group is committed to providing top-tier insulation solutions, including our glass wool, rock wool, and foam glass products. We offer customized, one-stop solutions for projects worldwide.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions