How does fire rated mineral wool insulation protect your building?

Worried about fire safety in your building? A fire can destroy everything. You need an insulation material you can trust to protect your property and the people inside.

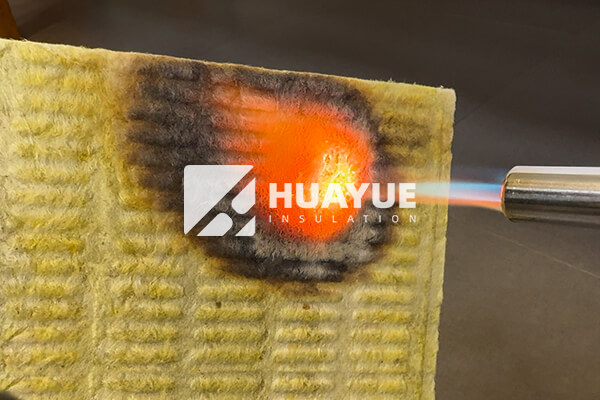

Fire-rated mineral wool insulation provides excellent fire protection. It’s made from stone, so it’s naturally non-combustible and can withstand temperatures over 1000°C (1832°F). This slows the spread of fire, giving people more time to escape and reducing property damage.

I’ve been in the insulation business for over 30 years. People often ask me about fire safety. It’s a critical topic. You need to know exactly what you’re getting. Let’s break down the details so you can make an informed choice for your project.

Is mineral wool insulation fire rated?

Choosing the right insulation can be confusing. Are you sure your choice meets fire safety codes? A wrong decision can have serious consequences when it comes to fire protection.

Yes, mineral wool insulation is fire-rated. It is classified as non-combustible, often achieving the highest fire safety ratings like Class A1 in Europe or Class A in North America. This means it will not contribute to a fire’s spread or produce significant smoke.

Understanding Fire Ratings

A fire rating is more than just a label. It tells you how a material behaves in a fire. The best rating is Class A1 non-combustible. This means the material will not contribute fuel to a fire. It also means it will not produce significant smoke or flaming droplets. Different regions have different standards, like ASTM in the United States and European Norms (EN) in Europe. At HUAYUE, we design our rock wool insulation to meet these strict global standards. Our products are tested and certified to be Class A1. This gives engineers and builders confidence that they are specifying a truly safe product for their projects.

How Mineral Wool Achieves Its Rating

The secret to mineral wool’s fire resistance is its raw material: natural volcanic rock. We take basalt rock and melt it at temperatures above 1500°C. This process is similar to a controlled volcanic eruption. The molten rock is then spun into fibers. Because the fibers start as rock, they have a naturally high melting point. They can easily withstand the heat of a typical building fire. We use a very small amount of binder to hold the fibers together, but this doesn’t affect the non-combustible nature of the final product. This inherent property makes it a reliable choice for fire-stopping applications in walls, floors, and ceilings.

What’s the difference between mineral wool and Rock Wool?

People use "mineral wool" and "Rock Wool" interchangeably. This can cause confusion. Are they the same thing, or are there important differences you should know about for your project?

"Mineral wool" is the general category for insulation made from rock or slag. "Rock wool" is a specific type of mineral wool made primarily from volcanic rock like basalt. All rock wool is mineral wool, but not all mineral wool is rock wool.

Types of Mineral Wool

There are two main types of mineral wool insulation. It’s important to know which one you are getting. One is rock wool, and the other is slag wool. While both are very effective, they start from different raw materials which affects their performance.

| Feature | Rock Wool | Slag Wool |

|---|---|---|

| Primary Raw Material | Natural volcanic rock (basalt) | A byproduct of steel manufacturing |

| Melting Point | Typically higher, over 1000°C | Very high, but can be slightly lower |

| Common Applications | High-temp industrial, fire barriers | General thermal & acoustic insulation |

| Our Focus at HUAYUE | We specialize in high-quality rock wool. | – |

Why the Name Matters

At HUAYUE, we manufacture rock wool. We believe that starting with pure, natural stone gives us a better final product. It provides consistent quality and superior performance, especially for demanding jobs. This includes fire protection in large buildings or insulation for high-temperature industrial tanks. We control the whole process, from melting the basalt to forming the final products. We offer rock wool in many forms, including boards, blankets, and pipe sections. This focus ensures every product that leaves our facility meets the highest standards for safety and performance.

Does Rock Wool provide fire protection?

You need more than just insulation. You need a material that actively protects your structure in a fire. Does rock wool just resist heat, or does it offer true fire protection?

Absolutely. Rock wool provides outstanding passive fire protection. It doesn’t just resist heat; it acts as a fire barrier. It contains fire in specific compartments, slowing its spread and maintaining structural integrity, which gives occupants valuable time to evacuate.

The Role of Passive Fire Protection

Passive fire protection means building safety directly into the structure. It works around the clock without needing activation, unlike active systems like sprinklers. Rock wool is a key part of this strategy. We manufacture high-density rock wool boards and specialty products specifically for fire-rated systems. These are used in walls, floors, and around structural steel. The purpose of these systems is to compartmentalize a fire. This means containing it in the room where it started. By doing this, rock wool helps prevent the fire from spreading through the entire building. This gives firefighters more time to arrive and control the situation.

More Than Just Stopping Flames

Rock wool’s dense structure is key to its performance in a fire. When exposed to extreme heat, it does not shrink, melt, or create gaps. Other insulation types can fail and leave spaces for fire to pass through. Rock wool maintains its form and integrity, holding the fire back. Another major benefit is that it does not release toxic smoke. In a fire, smoke inhalation is often a greater danger than the flames. By using a material that does not produce harmful smoke, you are creating a much safer environment for a building’s occupants.

Is Rock Wool 2 hour fire rated?

Projects often require a specific fire resistance rating, like 2 hours. Can you rely on rock wool to meet this critical requirement? The wrong material could mean a failed inspection.

Rock wool itself is non-combustible, but a "2-hour fire rating" applies to the entire assembly, like a wall or floor system. Rock wool is a crucial component in systems designed and tested to achieve a 2-hour or even higher fire rating.

Understanding Fire-Rated Assemblies

A fire rating isn’t for a single product. It’s for a complete building system. For a wall, this includes the steel or wood studs, the gypsum board layers, the fasteners, and the insulation inside the cavity. The entire assembly is built and then tested in a specialized laboratory. During the test, one side of the wall is exposed to intense fire. The test measures how long the wall stops the fire from passing through. It also measures how long it takes for the temperature on the cool side of the wall to rise to a dangerous level. A wall that passes these criteria for two hours earns a 2-hour fire rating.

How HUAYUE Rock Wool Contributes

Our high-density HUAYUE rock wool boards are made for these systems. They are designed to fit snugly between studs and stay in place, even under the stress of a fire. This is a critical function. If the insulation sags or melts, it creates a weak spot in the fire barrier. Our rock wool’s high melting point and stable structure ensure it performs its job. Engineers and architects specify all the system components, and we provide the technical data they need. They can specify our rock wool with confidence, knowing it is a reliable part of a proven fire-rated assembly.

Conclusion

For true fire protection, you need a non-combustible material. Rock wool is the superior choice for fire resistance, keeping buildings and people safe. We deliver that peace of mind.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions