Fire Rated Mineral Wool: How Fireproof Is Your Insulation?

Many worry about fire safety in building materials. Finding a reliable fire-rated insulation can feel overwhelming for facility managers and engineers.

Mineral wool insulation is naturally non-combustible and provides critical fire resistance, making it an ideal choice for fire-rated building assemblies and industrial applications.

When choosing insulation for tough industrial or safety-focused projects, I see fire safety come up first. Good insulation must do more than keep hot or cold inside. It must stand up to fire, limit its spread, and give staff more time to respond in an emergency. Let’s explore how mineral wool answers these needs.

Does mineral wool have a fire rating?

For facility managers aiming to meet safety standards, burning questions about fire ratings are common. Clear answers help you make the right call before you invest.

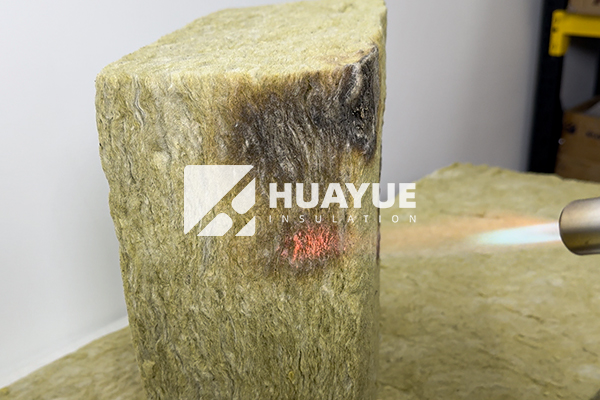

Yes, mineral wool has a fire rating. It is non-combustible, often carries the highest A1 Euroclass rating, and can withstand temperatures above 1000°C without melting, emitting smoke, or spreading flames.

When discussing fire ratings on job sites, I often compare test results. Some insulation products only claim to “resist” fire, but certified mineral wool stands apart. Its A1 classification means it will not contribute to fire growth under any circumstances. This comes from its volcanic rock base—usually basalt or slag—heated and spun into wool-like fibers.

The Euroclass A1 standard is Europe’s toughest. It means that even in direct flame or high-heat exposure, there is zero smoke release, no flaming droplets, and no burning. Mineral wool’s melting point is over 1000°C. In severe plant fires, this gives valuable time for fire response and safe evacuation. In my career, I have seen plant insurance claims require this proof before policies are written. Mineral wool passes EN 13501-1 tests for Euroclass A1 and ASTM E136 in the USA, which means global acceptance. This certainty covers both regulatory and practical demands for tank farms, pipe racks, or building cores where fire risk is not a theory, but a daily reality.

| Standard | Test Method | Result |

|---|---|---|

| Euroclass A1 | EN 13501-1 | Non-combustible |

| ASTM E136 | USA fire test | Non-combustible |

| Melting Point | Internal Testing | >1,000°C (1,832°F) |

With mineral wool, your insulation always supports the highest fire safety goals, wherever you build.

Is ROCK WOOL 2 hour fire rated?

There’s pressure to meet two-hour fire ratings for walls or tanks. Not all insulation passes. I remember many engineers asking how to be sure.

ROCK WOOL, a specific type of mineral wool insulation, can achieve a 2-hour fire rating when installed as part of a properly tested wall or barrier system.

ROCK WOOL refers to insulation made from molten volcanic rock. Its fibers do not burn, and when used in assemblies, it extends the fire resistance of structures. To meet a 2-hour rating, product selection is key. That means not only the mineral wool but also the wall design, facings, and installation. I have worked on projects where ROCK WOOL panels were certified in systems under UL 263, ASTM E119, and EN 1364.

By itself, ROCK WOOL will not combust, but official “2-hour fire rating” comes from the system passing a full-scale test. These tests measure the time a wall or floor can resist heat, flames, and prevent temperature rise on the other side. ROCK WOOL panels, often 50–100mm thick, with the right facings and sealants, frequently pass 120-minute (2-hour) tests. In my experience, with chemical or cryogenic storage, investors expect certificates stating 2-hour or even up to 4-hour ratings. Vendors must provide this documentation for each system.

Here is a simple way to check:

| Fire Rating | Test Assembly | Certification Body | Typical Thickness |

|---|---|---|---|

| 2-hour | UL 263/EN 1364 | UL, Intertek, SGS | 50-100mm |

If your project requires an exact 2-hour certificate, demand wall system test reports from your insulation provider.

Is mineral wool a fire block?

Many clients wonder whether mineral wool works as a “fire block” in cavities and voids. Codes in Europe and the US now require fire stopping as a must-have for energy upgrades.

Mineral wool acts as a fire block. Its high melting point, density, and non-combustibility stop fire and smoke from passing through wall voids, attics, and pipe chases.

Building codes call out “fire blocking” to stop fire from using wall or floor voids as a hidden path. Unlike open pathways or foam, mineral wool is rigid and stable under fire. I have cut and packed it into masonry gaps or around pipes where codes now demand fire resistance.

Mineral wool fits tightly, does not sag, and keeps shape under extreme heat. Placed between wall studs, under roof decks, or as pipe chase fill, it traps heat and flames at the source. This delays fire travel and smoke migration, giving people more time to exit and firefighters more time to act. Most importantly, mineral wool fire blocking does not lose performance with age or moisture—which is crucial in tanks or process plants where leaks are possible.

| Application Area | Fireblock Function | Performance |

|---|---|---|

| Wall Voids | Stop vertical fire travel | Non-combustible, Rigid |

| Floor Openings | Compartmentalize fire | Holds shape under heat |

| Pipe Chases | Seal around penetrations | Won’t shrink or compress |

Using mineral wool as a fire block is an easy and code-compliant way to improve fire safety in upgrades or new builds.

Can ROCK WOOL be used as a firestop?

I often get questions about whether ROCK WOOL can serve as a firestop around ducts, pipes, and cable trays—especially in industrial settings.

ROCK WOOL can be used as a firestop. When packed tightly into gaps and coated with approved fire-resistant sealants, it prevents the spread of fire and smoke through penetrations.

I have seen ROCK WOOL as a standard in engineered firestop systems. Firestops are required at all wall and floor penetrations that might leak flames or hot gases during a fire. Installers pack ROCK WOOL snugly around ducts or pipes. They then usually seal the exposed edge with intumescent or silicone firestop sealant to complete the barrier.

This combo is tested under UL 1479 and EN 1366-3, which mimic real fire conditions. As a non-combustible material, ROCK WOOL stays in place, bridges movement or vibration, and does not burn away. It is also water resistant, so firestop integrity lasts even in humid or leaky environments. I have worked on projects where ROCK WOOL replaced older fibrous or foam systems after audits showed those failed. Inspectors prefer firestop details with test reports and long-term documentation.

| Penetration Type | Firestop Method | Certification Standard |

|---|---|---|

| Duct/Pipe | ROCK WOOL + Firestop Sealant | UL 1479, EN 1366-3 |

| Cable Tray | ROCK WOOL + Intumescent Sealant | Up to 4 hours |

ROCK WOOL’s ability to serve as a firestop is a cost-effective, reliable solution for long-term safety compliance.

Conclusion

Mineral wool and ROCK WOOL insulation deliver trusted, certified fire safety, making them top choices for fire-rated, code-compliant projects in modern industry.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions