Fibreglass duct insulation: Is it the best choice for air ducts?

Poor duct insulation leads to energy loss and high bills. Ducts often leak heat or cool air, wasting energy and money each month.

Fiberglass insulation is a top choice for ductwork because it prevents heat loss, reduces condensation, and increases energy efficiency. Use batts, rolls, or pre-shaped pipe insulation for best results.

If you’ve ever managed energy systems, you know how important good insulation for ducts is. Poor insulation causes discomfort and drives up costs. I always recommend fiberglass liner, blanket, or rigid board insulation for air ducts. Years ago, a client faced frequent temperature swings and high HVAC bills until we added fiberglass products from our factory. The difference was dramatic. Let’s look closer at why fiberglass is often chosen, and what users should consider before installing on ductwork.

Can you use fiberglass insulation on ductwork?

Leaky or poorly insulated ductwork makes HVAC systems inefficient. When ducts are bare, homes and buildings lose energy, making heating and cooling costly.

Fiberglass insulation is suitable for ductwork. It comes in blankets or boards and is applied around the duct surface or inside as lining. It resists heat transfer and dampens noise.

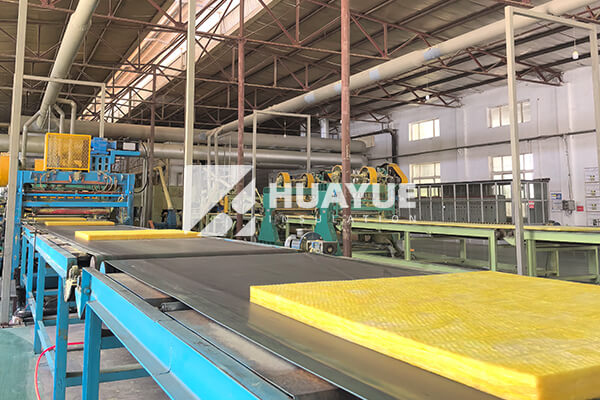

Fiberglass insulation works well with both rectangular and round ducts. In my experience outfitting commercial buildings, we used pre-cut fiberglass pipe sections and flexible blanket rolls for larger trunk lines. The insulation is easy to cut or shape, allowing tight coverage around every bend or joint. Manufacturers like HUAYUE offer customizable glass wool products: boards for flat surfaces, blankets for wrapping, and pipes for direct-fit cylindrical ducts. The A1 fire rating ensures long-term thermal safety, and the flexible quality helps installers avoid gaps at joints.

Table 1: Forms of Fiberglass Insulation for Ducts

| Product Type | Application Site | Advantages |

|---|---|---|

| Board | Rectangular ducts | High strength, stable fit |

| Blanket | Duct wraps | Flexible, easy to install |

| Pipe | Circular ducts | Custom fit, quick coverage |

Using fiberglass insulation on ductwork is simple, versatile, and effective for different types of layouts.

What insulation is best for ductwork?

Choosing insulation for ducts affects both comfort and cost. Some materials are cheap but perform poorly, while others offer long-term benefits.

Fiberglass and mineral wool are most recommended for ductwork. Fiberglass provides excellent thermal resistance, fire safety, sound damping, and ease of installation.

Fiberglass duct insulation is popular for several reasons. It serves both residential and industrial applications. As a manufacturer, we supply it in custom sizes for projects worldwide. Fiberglass has good R-value and controls temperature extremes, making it ideal for HVAC. In our experience, clients in Germany, the United States, and South Asia prefer fiberglass for duct insulation because the performance stays consistent year over year.

Here’s a comparison table highlighting fiberglass versus other materials:

| Insulation Type | Thermal Efficiency | Fire Resistance | Cost | Pros | Cons |

|---|---|---|---|---|---|

| Fiberglass | High | A1 Class | Medium | Durable, easy to fit | Can irritate skin |

| Mineral Wool | High | A1 Class | Higher | Sound dampening, stable | Denser, heavier |

| Foam (polyurethane) | Medium | Combustible | Lower | Lightweight, quick install | Lower fire safety |

| Foil-faced Blanket | Medium | Variable | Lower | Reflects radiant heat | Not for all ducts |

Fiberglass is effective for most ducting situations, especially where fire safety and longevity matter.

Is fiberglass insulation effective?

Old insulation fails over time. Leaky ductwork and poor materials let conditioned air escape, making systems work harder.

Fiberglass insulation on ducts is very effective. It reduces heat loss, dampens noise, prevents condensation, and meets strict fire resistance standards.

I have seen fiberglass insulation perform over decades in both humid and dry climates. Our HUAYUE glass wool is tested to ASTM standards, with stable R-values across years of service. For a large chemical plant in Germany, we supplied custom-sized duct blankets and boards. Even five years later, the insulation maintained its thickness, softness, and resilience. This prevented water buildup and corrosion. The plant’s maintenance manager, Hans, reported major energy savings and reduced downtime.

Fiberglass insulation also supports long-term savings by improving HVAC efficiency and indoor air comfort. It is soft enough to wrap tightly, yet strong enough to resist compression. Our latest no-formaldehyde series meets stringent global standards, making installations safer for workers and occupants.

Can fiberglass insulation of an air duct grow mold?

Moisture and poor airflow inside ducts encourage mold. Mold leads to health risk, odor, and system damage.

Fiberglass insulation does not support mold growth if kept dry and covered with vapor barriers or foil facings.

In practice, I always recommend using foil faced fiberglass blankets or vapor-barrier wraps on the exterior of duct insulation, especially for chilled water or cooling ducts. This prevents moisture from penetrating the fibers. Mold only grows if the insulation gets wet and remains damp, so proper sealing and wrapping is essential. Some modern products, including HUAYUE’s glass wool, feature hydrophobic treatments, making water absorption nearly impossible. Years ago, a school retrofit used old fiberglass insulation around ducts, leading to mold issues. We replaced it with new, vapor-barrier wrapped insulation and eliminated the problem long-term by improving duct layout and air flow.

Table 2: Preventing Mold in Fiberglass Duct Insulation

| Risk Factor | Impact on Mold Growth | Prevention Strategy |

|---|---|---|

| Moisture leaks | High | Use vapor barrier wrap |

| Poor ventilation | Medium | Ensure air flow, dry ducts |

| Damaged covering | High | Replace torn insulation |

Fiberglass insulation remains safe and mold-free when installed properly, with attention to moisture control.

Conclusion

Fiberglass duct insulation is versatile, effective, safe, and durable for HVAC systems when installed and maintained properly.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions