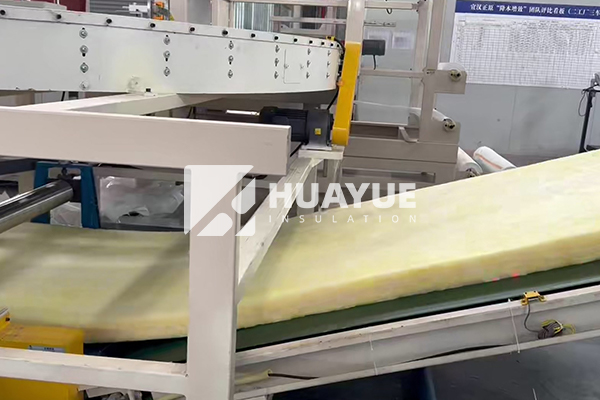

Fiberglass Insulation Roll - What’s Inside the Roll?

When planning to insulate a space, you want materials that offer strong performance and fit the project needs. Fiberglass insulation rolls stand out, but questions remain.

Fiberglass insulation rolls, generally, are available in standard sizes like 15 or 23 inches wide and 39 to 80 feet long. Their thickness varies based on R-value, offering tailored choices for walls, attics, and crawl spaces.

When you look at the shelves at a hardware store or scroll online, different rolls can be confusing. Some are huge, some are small. Every roll has a specific use. If you buy the wrong size, you waste money and time. Let’s look closer so you feel sure about your choice.

How big is a roll of fiberglass insulation?

If you’ve ever stared at a product label and wondered, “Will this fit my space?” you’re not alone. It’s a common concern for engineers and facility managers.

A standard roll of fiberglass insulation is usually 15 or 23 inches wide, 39 to 80 feet long, and has thicknesses varying from 3.5 to 12 inches depending on the needed R-value. Rolls are designed for coverage, making installation fast.

There is a reason insulation rolls appeal to professionals and homeowners. Wide rolls cover more area in fewer passes. You can finish a wall section or attic faster, with fewer seams. Smaller rolls, like those used for crawl spaces, let you get into tight corners. When specifying the size, I always look at the project blueprints, then match the roll width to stud spacing. Length matters too, especially for continuous runs, so long rolls minimize wasted cuts.

Here’s a table that shows common roll sizes:

| Roll Width | Roll Length | Thickness | Coverage per Roll |

|---|---|---|---|

| 15 inches | 39 feet | 3.5 inches | 48.75 sq ft |

| 23 inches | 39 feet | 3.5 inches | 74.75 sq ft |

| 15 inches | 80 feet | 6 inches | 100 sq ft |

| 23 inches | 80 feet | 6 inches | 153 sq ft |

Project needs help you choose. If you are insulating between 16-inch studs, go with 15-inch rolls. For 24-inch studs, choose 23-inch width. The thickness matches your climate zone’s recommended R-value.

Which is better, roll or batt insulation?

Choosing between insulation types can feel overwhelming. I’ve made this decision many times, especially for large tanks or wall cavities.

Batt insulation is pre-cut to fit standard stud and rafter spaces, making it easy to handle, especially for small projects. Rolls provide longer, continuous coverage, which reduces seams and speeds up installation for larger areas.

The main differences come down to job size and layout. If you need to insulate a regular wall with lots of studs, batts are the familiar choice. They fit between studs with little trimming. If the area is large, like an attic or long tank wall with fewer interruptions, rolls become the efficient choice. The fewer seams you have, the fewer potential points for air leaks. When I work on large industrial tanks, rolls help us move fast and achieve good thermal coverage. For tricky shapes or irregular areas, I sometimes combine both, cutting the roll where needed. It’s about matching the material to the job.

| Feature | Batt Insulation | Roll Insulation |

|---|---|---|

| Best Use Case | Standard stud walls | Large open spaces |

| Installation | Easy to handle | Fast for big areas |

| Seams | More seams | Fewer seams |

| Waste | More off-cuts | Less waste |

| Flexibility | Good for odd shapes | Best for uniform |

Making the right choice saves labor, reduces waste, and maximizes energy performance.

Why is fiberglass insulation so expensive?

Sticker shock hits hard when reviewing a materials budget. It’s a common challenge for procurement teams and engineers.

Fiberglass insulation costs more than some other insulation materials because it requires precise manufacturing, high-quality glass raw materials, energy-intensive production processes, and tight certification standards for fire safety and performance.

All cost factors add up. First, the glass itself is not cheap. It needs to be pure, without impurities, which makes the insulation strong and reliable. The factory must melt glass at extreme temperatures, pulling it into fine fibers. The process uses lots of energy and special machinery. Next, quality testing is strict. Products must meet ISO, CE, and test marks for international markets. Each step requires skilled labor. For buyers who care about non-combustibility, long service life, and moisture resistance, these costs come with peace of mind. In my experience, reliable performance far outweighs initial cost, especially for projects where insulation failure leads to major repair bills.

| Reason | Impact on Cost |

|---|---|

| Premium glass material | Higher base material price |

| Specialized production | Increased manufacturing cost |

| Certification requirements | Extra quality control cost |

| Long lifespan | Long-term value |

Choosing certified suppliers helps ensure you pay for genuine quality, not just marketing.

What is the lifespan of fiberglass insulation?

Planning a project means thinking years ahead. Facility managers and engineers need insulation that stands the test of time.

Fiberglass insulation has a lifespan of 25-50 years when installed properly and kept dry, exceeding most other insulation materials in longevity due to its resistance to moisture, pests, and fire.

I’ve visited plants where fiberglass insulation looks brand new after decades in use. The reason is simple: it does not rot, attract rodents, or soak up water. If sealed well, it performs for as long as the building stands. The key is avoiding leaks and keeping vapor barriers intact. In industrial tanks, I trust fiberglass because it resists chemical exposure and holds its thermal value. Over the years, maintenance expenses stay low. By knowing this, I feel confident recommending fiberglass insulation to customers for safety, durability, and value.

| Insulation Type | Typical Lifespan (Years) |

|---|---|

| Fiberglass | 25-50 |

| Rock wool | 20-40 |

| Rubber foam | 15-25 |

| Cell glass | 30-50 |

If you want peace of mind over decades, fiberglass insulation is a strong choice.

Conclusion

Fiberglass insulation rolls offer flexible sizing, strong performance, long lifespan, and reliable quality, making them a top choice for lasting energy savings.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions