Fiberglass Insulation Board: Is It the Right Choice for Your Project?

Insulating your building well can feel overwhelming—choose wrong, and you pay for it for years. So what really defines a good insulation board?

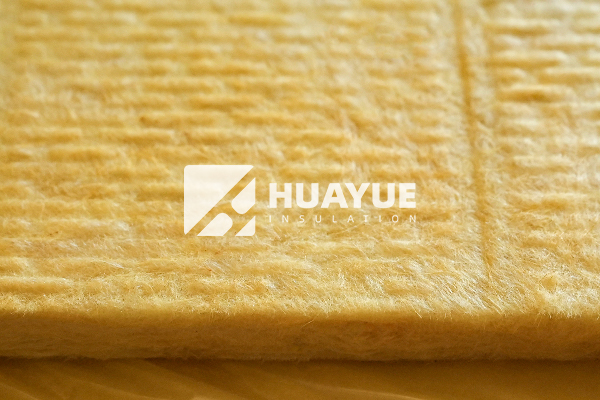

Fiberglass insulation board is a lightweight, fire-resistant, and moisture-tolerant material that reduces heat transfer, making it a strong option for energy-efficient buildings and industrial applications.

If you care about reducing energy costs, keeping condensation under control, or complying with strict safety codes, you will want to understand what fiberglass insulation board can do. I have spent years working with different insulation materials, and I know why engineers and project managers keep coming back to fiberglass. Let me walk you through everything you need to make a smart, informed choice.

What is fiberglass board insulation?

For years, many people have struggled to find insulation that lasts, fights moisture, and doesn’t compromise fire safety. The promise of fiberglass board solutions has caught a lot of attention. So what makes fiberglass insulation boards special?

Fiberglass board insulation is made from fine glass fibers bonded into stiff panels. It delivers consistent, long-lasting thermal and acoustic performance for wall, roof, and industrial tank applications.

Fiberglass board insulation starts with raw glass heated to high temperatures. Manufacturers spin the glass into fibers less than the width of a human hair and bind them with a resin. The material is then pressed into rigid panels. I have watched this production process many times, and even after so many years in the industry, I am always impressed by the uniform density and thickness the machines achieve.

Here is a breakdown of why people trust fiberglass boards for both commercial and industrial uses:

| Key Feature | Description | Benefit |

|---|---|---|

| Fire Safety | Non-combustible; resists fire up to 650°C | Meets codes; safe for tanks/walls |

| Moisture Tolerance | Naturally resists mold, rot, and bacteria | Reduces CUI risk |

| Stable R-Value | Delivers constant insulation performance over decades | Energy cost savings |

| Acoustic Control | Absorbs sound over a wide frequency range | Quiet indoor environments |

| Easy Installation | Rigid panels cut easily, hold shape | Time-saving on-site |

I remember the first time I recommended fiberglass board for an LNG tank in northern China. The client reported no water damage or insulation drop-off even after five harsh winters. This long-term stability is why project engineers like Hans Müller in Germany prefer it—especially when the stakes are high.

Is fiberglass insulation better than foam board?

Some facility managers worry they might miss out on even better performance. Foam insulation boards have their own fans. So, how does fiberglass compare to foam board?

Fiberglass insulation boards resist fire and moisture better than foam boards, though foam often provides higher R-value per inch. But fiberglass comes out ahead for safety and long-term reliability in tough environments.

Let’s compare the key differences side by side:

| Feature | Fiberglass Board | Foam Board (XPS/EPS/Polyiso) |

|---|---|---|

| R-Value/Thickness | Medium (R-4 to R-6 per inch) | High (R-5 to R-7 per inch) |

| Water & Vapor Resistance | High; resists moisture | Depends on closed cell structure |

| Fire Resistance | Non-combustible | Can burn or emit toxic smoke |

| Lifespan | 30+ years | Can degrade with UV/water |

| Handling | No harmful smoke, easy to cut | May require care with adhesives |

| CUI Risk for Tanks | Low | Higher under jackets/seams |

I watched Hans and his team debate fiberglass vs. foam for a chemical tank rebuild. The local safety codes demanded a Class A noncombustible rating. In that setting, fiberglass was the only practical answer. Foam was lighter and slightly thinner, but Hans was not ready to risk his reputation or increase his maintenance cycles. As a supplier, I agree—choose foam where you need maximum R-value in tight space, but use fiberglass when longevity, safety, and moisture resistance matter most.

Is fiberglass insulation good or bad?

People ask if fiberglass is truly "safe"—they have heard things about dust or performance drops over time. In my experience, these concerns are worth answering openly.

Modern fiberglass insulation boards are considered safe and effective. They do not emit harmful fumes, resist fire and moisture, and retain performance for decades with minimal maintenance.

In the past, some installers worried about itchy fibers. Today’s products use improved binders and pre-encapsulation, so handling complaints are rare, especially in rigid board form where fibers are contained. The main health risk comes only if workers saw or break boards without protection; following normal safety protocols avoids this.

From a quality and long-term performance perspective, here’s a breakdown of “good” and potential “bad,” based on real application feedback:

| Factor | Good | Bad (if any) |

|---|---|---|

| Fire & Smoke | No toxic gas; exceeds most safety laws | None |

| CUI & Mold | Resists both | None if installed dry |

| Dimensional Shift | Holds shape; no shrinking | Poor fit if cut imprecisely |

| Air Quality | No off-gassing | Minor fiber dust at install |

| Cost-Effectiveness | Medium upfront, low life cycle cost | Slightly higher than base foam |

I remember being asked about corrosion under insulation (CUI) by a refinery customer. After ten years, they sampled sections of glass wool board and found zero corrosion, with the board’s thickness and color unchanged. That is why I trust this material for industrial tanks and demanding jobs.

Is fibre board a good insulator?

Some people confuse fiberglass board with generic “fiber board” made from organic fibers. So, is fiberglass board really among the best insulators?

Fiberglass insulation board has a proven track record as a reliable, safe, and effective thermal insulator in commercial, industrial, and residential situations. It remains a top choice for walls, roofs, and tanks.

Let’s compare fiberglass with other "fiber board" types:

| Insulator Type | Main Material | Typical R-Value/inch | Flame Spread | Moisture Performance |

|---|---|---|---|---|

| Fiberglass Insulation | Glass fibers | 4.0–4.6 | Near 0 (non-comb.) | No rot, no mold, stable R-value |

| Mineral Wool Board | Basalt rock | 4.0–4.3 | Non-combustible | Water resists, but heavier |

| Wood Fiber Board | Organic fibers | 3.0–3.5 | Flammable | May swell, degrade when damp |

| Extruded Polystyrene | Synthetic foam | Up to 5.0 | Can burn/smoke | Good unless UV/damaged |

From chemical tanks in Germany to large cold storage warehouses in Asia, I have watched fiberglass board outperform other types on fire safety, stable R-value, and ease of installation in complex layouts. The only cases where I might choose mineral wool or foam are when very high compression loads or maximum R-value per inch are the top priorities.

Conclusion

Fiberglass insulation board is a reliable, fire-safe, and moisture-resistant material that works long-term in both industry and construction, making it a solid choice for a wide range of projects.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions