Eco Batt Insulation: What You Need to Know?

Eco batt insulation is changing how we think about keeping buildings comfortable and energy-efficient. Many people wonder what exactly it is, how it works, and if it’s right for their projects.

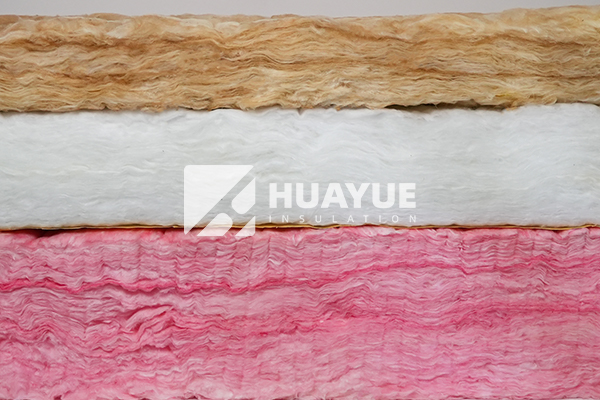

Eco batt insulation is a kind of fiberglass batt that uses a high percentage of recycled glass and plant-based binders instead of traditional petrochemical binders. It’s highly effective for thermal and acoustic insulation, making it a strong choice for modern construction and renovations.

There’s a lot of talk about better insulation these days, but not all solutions are equal. I’m always looking for materials that actually perform well, last long, and don’t add problems down the road. Eco batt insulation keeps coming up in these conversations. Let’s break down what makes it different.

What is eco batt insulation?

Eco batt insulation seems confusing at first, especially if you’re used to standard fiberglass products. Most people want to know if the “eco” label means it really helps them and the environment.

Eco batt insulation is made by mixing recycled glass with a renewable, plant-based binder, instead of the petroleum-based adhesives found in traditional fiberglass batts. This design makes it less toxic and easier to handle, but still efficient at stopping heat and sound.

Eco batt insulation stands out because of its material composition and its benefits to indoor air quality. Many regular fiberglass batts can off-gas chemicals or use binders that are not environmentally friendly. Eco batt insulation swaps out petrochemical binders for ones made from rapidly renewable materials, usually cornstarch or similar biopolymers. This small change has a big impact. Not only does it mean fewer chemicals indoors, but the product also handles more easily. It doesn’t itch like traditional fiberglass. It’s also Greenguard certified for low emissions. Contractors and homeowners often notice the insulation has less odor and releases less dust during installation.

Here’s a simple comparison:

| Characteristic | Regular Fiberglass Batts | Eco Batt Insulation |

|---|---|---|

| Binder Type | Petrochemical | Plant-based (renewable) |

| Recycled Content | Low-moderate | Up to 60% |

| VOC Emissions | Moderate | Low |

| Handling Comfort | Itchy/irritating | Softer, less itch |

| Sustainability | Standard | High |

I recently helped a client select insulation for a sustainable building. They chose eco batt after seeing how easy it was to cut and fit, how little dust it produced, and the strong R-values matched their energy goals.

What does batt mean in insulation?

People wonder what a “batt” actually is. The word appears everywhere, but many do not know how it’s different from other insulation options.

Batt means insulation that is pre-cut into flat, rectangular pieces. It usually comes in rolls or panels, made mainly from fiberglass, mineral wool, or sometimes cotton. Batts are designed to fit snugly between wall studs, floor joists, or rafters.

Batt insulation is very popular because it is simple and fast to install. The uniform shape lets you quickly fit pieces into standard framing throughout a building. This means labor costs are usually lower than with loose-fill or spray foam insulation.

Here’s a quick table that shows how various insulation forms compare:

| Insulation Type | Typical Uses | Application Method | Pros | Cons |

|---|---|---|---|---|

| Batt | Walls, attics, floors | Laid or fitted between studs | Fast install; predictable coverage | Gaps if not well-fitted |

| Loose-fill | Attics, irregular spaces | Blown in | Fills odd gaps | Can settle over time |

| Spray foam | Walls, roofs | Sprayed/expands | Air seal; strong R | High cost |

I often recommend batts for projects with a lot of wide-open walls or unfinished attics. They cover space quickly, and you can measure exact R-value needed for energy code.

What is Eco Roll insulation made of?

I get asked if eco rolls are just marketing or if there’s really something different about the materials inside.

Eco Roll insulation is made primarily from recycled glass fibers, sometimes up to 60%, and bonded with an acrylic or bio-based binder instead of formaldehyde or other petroleum chemicals. This makes it more sustainable and less toxic without sacrificing performance.

Eco Roll is similar to Eco Batt as both belong to a new generation of “greener” fiberglass products. The recycled content comes from post-consumer glass, like bottles and windows, which are cleaned and melted down into fibers. The binder is key. Instead of using formaldehyde-based resins, manufacturers use plant-based adhesives made from starches or sugars. This leads to air quality certifications and helps meet green building certifications like LEED or WELL.

Here’s a look:

| Component | Percent content | Source |

|---|---|---|

| Recycled glass | 50 – 60% | Post-consumer waste |

| New glass | 40 – 50% | Silica sand, minerals |

| Binder | Small percent | Plant-based polymer |

The push for eco-friendly materials goes beyond just the environment too. I’ve noticed job sites feel less dusty and workers enjoy softer handling. Eco Roll and Eco Batt both ship compressed, reducing transport costs and storage space.

Is Batt insulation good or bad?

Many people want a simple answer. Is batt insulation a smart choice, or does it have hidden downsides compared to other types?

Batt insulation offers excellent value for the cost. It provides good thermal performance if installed correctly. Potential downsides include gaps where insulation isn’t fit tightly, which can reduce performance. Choosing high-quality batts, like eco batt, reduces these risks.

Batt insulation remains the most commonly used format in most countries for a reason. When batts are cut accurately to fit each cavity, and installed without major gaps, the performance is reliable. The risk comes when installers leave gaps, compress batts, or don’t seal around obstacles. This can let air leak, cutting energy efficiency. Eco batts may perform even better because the fibers are engineered for even distribution.

Here are the main pros and cons:

| Advantage | Disadvantage |

|---|---|

| Cost-effective | Gaps can form if not well installed |

| Fast, easy installation | Can settle or compress over time |

| Consistent R-values | Not air or vapor barrier |

| Good fire and pest resistance | Sensitive to moisture (in some types) |

I have seen that batt insulation works very well for most wall and attic jobs where you can reach all the spaces. For basements, slab foundations, or odd-shaped areas, you may want to look at spray foam or blown-in products instead. Also, batt materials continue to get better. Eco batts, for example, don’t only cut energy loss, but also reduce environmental impact, adding another layer of value over traditional fiberglass.

Conclusion

Eco batt insulation uses better materials, fewer chemicals, and works just as well as standard batts. It’s a smart, cost-effective, and sustainable choice for most buildings.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions