Benefits of Rockwool Insulation: Why Does It Matter for Industrial and Home Applications?

When it comes to insulation, problems like heat loss, fire risk, and moisture damage never seem to go away.

Rockwool insulation increases energy efficiency, improves fire safety, and blocks moisture. It has high durability and does not shrink or settle, which ensures reliable, long-term performance in both industrial and residential settings.

Good insulation solves many costly headaches. Rockwool stands out for its superior thermal, acoustic, and fire-resistant features. My own experience in the field has shown that choosing high-quality rockwool can cut maintenance and energy costs for years. Let’s dive into how rockwool insulation works, its unmatchable advantages, possible downsides, and answers to common concerns.

What is the advantage of ROCK WOOL insulation?

Insulation problems frustrate project managers. Poor materials lead to heat loss, condensation, and even fire risks.

Rockwool insulation delivers superior thermal resistance, excellent sound absorption, and outstanding fire protection. It resists water, settles less, and can operate up to 700℃ when made from basalt, making it perfect for tough industrial and home use.

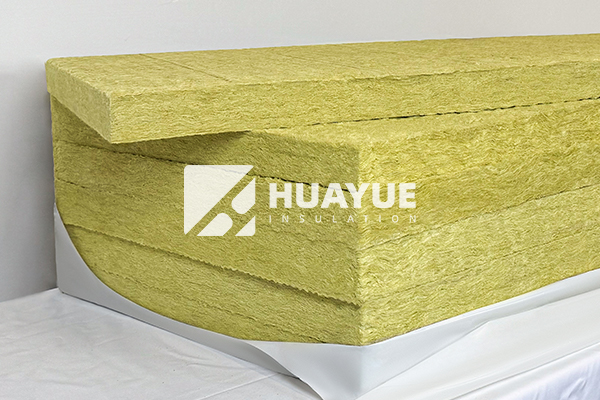

Rockwool insulation is made using volcanic basalt, which is what sets our product apart from others on the market. Many competitors use traditional mineral wool, which is yellow and not as strong. Our basalt-based rockwool appears green and has very fine fiber diameters. This means better insulation ability, less itchiness when handled, and a smoother, more consistent texture. Fine fibers are key for improved fire resistance and better soundproofing.

The material’s unique structure stops water from soaking in, blocking mold and decay. I’ve found that this waterproof design is especially important for tanks and piping in industrial settings where moisture exposure is a concern. Basalt-based rockwool performs reliably up to 700℃, which is far higher than the 500℃ ceiling for most mineral wool insulation. That high temperature limit means more real-world safety on chemical tanks, refinery vessels, and building applications where fires or overheating could happen.

Our rockwool also manages sound well because its dense, interconnected fibers absorb vibrations easily. That means quieter working environments and better comfort in buildings. Whether it’s for cryogenic tanks, rooftop piping, or energy-efficient homes, rockwool insulation brings multiple advantages that can’t be matched by lower-grade insulation materials.

| Feature | Mineral Wool (Traditional) | Our Basalt Rockwool |

|---|---|---|

| Material Color | Yellow | Green |

| Fiber Diameter | Coarse | Fine |

| Itchiness | Often itchy | Not itchy |

| Maximum Service Temp | ~500℃ | Up to 700℃ |

| Water Resistance | Moderate | Excellent |

| Fire Protection | Good | Outstanding |

What are the downsides of ROCK WOOL insulation?

People often think rockwool is perfect and worry less about its weak points. But every product has some limits.

Rockwool insulation can be more expensive upfront, it needs protective gear during installation, and its high density means extra handling care is needed compared to lightweight foams.

When installing rockwool, you need gloves and masks because small fibers can irritate the skin and lungs, especially if the product is not high quality or the fibers are large and rough. Our basalt rockwool improves this with fine fibers that are gentle and less itchy, but it’s best to use protection anyway. The higher upfront cost of rockwool can be a hurdle for some buyers compared to cheaper mineral wool or foam products. That said, the long-term savings in energy, maintenance, and fire protection pay off over the years.

Rockwool’s density makes handling bulky panels or rolls more challenging for installers. It is heavier than foam insulation, so more labor and planning might be needed on big projects. But, that density also means better performance and durability. Unlike foam, rockwool does not shrink or break down over time. It can keep tanks and buildings safe for decades without needing frequent replacements.

For chemical tank and cryogenic tank applications, I always recommend considering both the installation and lifecycle costs. The superior fire rating and moisture resistance make rockwool worth the extra effort during setup.

| Downside | Basalt Rockwool Mitigation |

|---|---|

| Cost | Long-term savings outweigh upfront |

| Handling Difficulty | Denser, needs careful placement |

| Skin/Lung Irritation Risk | Fine fibers, wear PPE |

| Bulkiness | Plan logistics, training |

Will mice chew through ROCK WOOL insulation?

Rodent problems haunt facility managers. Mice chewing insulation leads to damage and costly repairs.

Rockwool insulation is not attractive to mice because it has no food value, and its dense, rough texture deters rodents from chewing or nesting in it.

Mice might chew foam insulation or soft organic materials. On the other hand, rockwool’s mineral fibers are tough and non-edible. In my own practice, I’ve seldom seen signs of mouse activity in tanks or pipes insulated with basalt rockwool. The material’s density and scratchy feel mean mice do not like to burrow or nest within it. For industrial storage tanks, this feature keeps the insulation undisturbed and the underlying steel or concrete protected.

However, no solution is perfect. If there is a major infestation, rodents may try to get through anything, but rockwool is among the least likely to attract them. Routine inspections and clean storage practices always help, but having insulation that is unattractive to pests provides peace of mind.

| Insulation Type | Susceptible to Mice | Reason |

|---|---|---|

| Foam | Yes | Soft, chewable |

| Mineral Wool (Traditional) | Rarely | Tough, less food value |

| Basalt Rockwool | Almost Never | Dense, mineral-based |

Do roots grow through ROCK WOOL?

Plant growth is a common problem near foundation walls, buried pipes, and outdoor tanks.

Roots do not grow through dense rockwool insulation, especially basalt rockwool, because the fibers form a rigid barrier that plants cannot penetrate.

Rockwool is made to be tough and non-biodegradable, so it blocks roots and prevents plant damage to underlying structures. I have seen pipes and tanks in green, wet environments stay undamaged by root growth when wrapped with high-density rockwool. Some commercial growers even use special rockwool cubes to anchor plants without letting roots escape, showing how well rockwool contains and blocks root systems.

Competition-grade rockwool is recognized for this property in both industrial use and horticulture. Unlike soil or organic insulation materials, rockwool’s rigid structure and water resistance stop roots from entering and damaging systems. This keeps tanks, piping, and foundations safe for years. For landscaping and facility managers, this means lower maintenance and longer-lasting insulation performance.

| Application | Risk of Root Growth | Recommended Solution |

|---|---|---|

| Pipes in Soil | High with soil | Basalt rockwool wrap |

| Below-grade tanks | Medium with foam | High-density rockwool |

| Greenhouse Cubes | Controlled inside | Rockwool blocks roots |

Conclusion

Rockwool insulation offers unmatched fire resistance, water blocking, and durability, with basalt-based types reaching the highest industrial standards and ensuring long-term protection for many applications.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions