Air duct fiberglass insulation: Is it the right choice for your building?

When people choose insulation for air ducts, they usually want to solve condensation, temperature loss, and noise problems.

Fiberglass insulation is commonly used for air ducts because of its effective thermal properties, fire resistance, and sound-dampening qualities. It keeps airflow temperatures stable, reduces energy loss, and controls condensation.

Many building owners and engineers want reliable performance from air duct insulation. This means reducing wasted energy, controlling moisture, and meeting safety regulations — all while sticking to a budget. The right insulation lets you save on running costs and maintenance. With these practical benefits, it’s no wonder fiberglass is often chosen. Let’s explore all the answers people want when deciding how to insulate ductwork.

Can you put fiberglass insulation around ductwork?

Some people are concerned about whether wrapping ducts with fiberglass will actually solve issues like sweating or energy waste, or if it will just create new problems to deal with.

Yes, you can wrap ductwork with fiberglass insulation. It helps prevent condensation, keeps the temperature stable, and meets fire safety codes, making it a widely approved solution for HVAC systems.

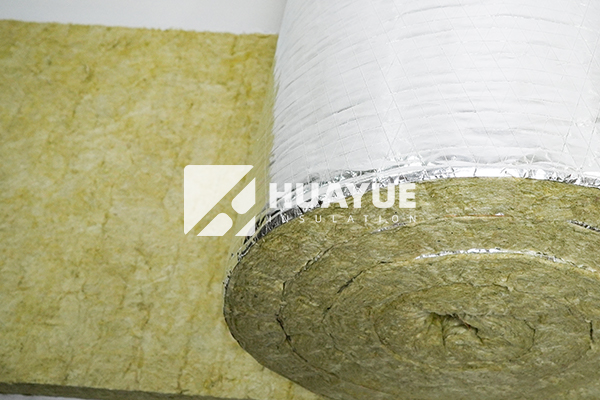

When I first helped a team upgrade duct insulation in a manufacturing plant, we wrapped every major air duct with fiberglass batts. The insulation had an aluminum foil vapor barrier facing outward, so we avoided moisture problems and held the insulation in place with metal bands. We sealed all seams with HVAC tape. Fiberglass works best when there are no gaps or compressions, since it needs to trap air for full thermal efficiency. The right thickness depends on the climate and how far the ducts run. In places with high humidity, the vapor barrier is critical for controlling condensation and avoiding corrosion under insulation (CUI).

Table: Comparing common insulation materials for ductwork

| Material | Thermal Performance | Fire Resistance | Moisture Control | Cost | Ease of Installation |

|---|---|---|---|---|---|

| Fiberglass | High | Excellent | Good (with vapor barrier) | Moderate | Easy |

| Foam Board | Very High | Good | Excellent | High | Intermediate |

| Rock Wool | High | Good | Good | Moderate | Easy |

Fiberglass is flexible, affordable, and up to code for fire safety. It usually comes pre-faced with a vapor barrier.

What is the best insulation for air ducts?

Builders and engineers often debate which insulation really protects ducts from temperature swings, condensation, and damage—while still being easy to install and cost-effective.

Fiberglass is the most popular choice for air duct insulation thanks to its strong thermal properties, noise control, non-combustibility, and affordability. Alternatives like foam board can offer higher insulation but at increased cost.

I’ve compared several duct insulation materials on big retrofit projects. Foam board and rock wool have their fans. Foam board delivers high R-values but costs more and can be harder to install on round or irregular ducts. Rock wool is mold-resistant and performs well, but its application in air ducts is less common due to availability and local code compliance. Fiberglass is flexible—fit for all shapes of ductwork, easy to cut or handle, and widely available. It absorbs sound, helping with noise management in offices, schools, and hospitals. Plus, the vapor barrier option keeps out moisture and maintains long-term integrity. For most air duct installations, fiberglass combines performance, budget, and safety better than anything else.

Key evaluation factors:

| Factor | Fiberglass | Foam Board | Rock Wool |

|---|---|---|---|

| R-Value per inch | 3.0–4.0 | 4.0–6.5 | 3.3–4.0 |

| Water Resistance | With barrier | Excellent | Good |

| Fire Rating | Non-combustible | Non-combustible | Non-combustible |

| Sound Dampening | Good | Fair | Good |

| Cost | Moderate | High | Moderate |

Fiberglass strikes a solid balance for daily building needs.

What is the 2 foot rule for ductwork?

Installers and inspectors often hear talk about “rules” for ductwork, but not everyone understands why the 2 foot rule matters when positioning insulation and ducts.

The 2 foot rule typically refers to keeping supply and return ducts at least 2 feet apart to prevent energy loss and airflow mixing. It also helps moisture control by preventing condensation zones.

Building code inspectors in my city always check duct layout before signing off on an HVAC installation. When supply and return ducts are too close, warm and cool air can mix, causing inefficiency. Condensation risk goes up, especially where cold air meets warm areas. On a hospital renovation, we faced constant sweating on return ducts until we spaced them a full two feet apart and upgraded the insulation. Good separation helps air circulate as designed and lets fiberglass insulation work without having energy “leak” zones or extra humidity. Always confirm your installation meets the spacing requirement for your duct type and insulation thickness. This simple step reduces headaches later.

Practical installation factors

| Item | Risk Without Rule | Benefit With Rule |

|---|---|---|

| Energy Efficiency | Decreases | Increases |

| Risk of Condensation | Higher | Lower |

| Air Quality | Mixed | Controlled |

Spacing ducts properly allows insulation performance to shine.

Does fiberglass insulation allow air flow?

People sometimes think fiberglass insulation might allow leakage or compromise the airflow in flexible duct systems.

Fiberglass insulation does not allow air to flow through it. The fibers trap pockets of air, which provide excellent thermal resistance but do not let airflow pass through.

I remember a plant engineer who asked me whether adding thick fiberglass batts meant the ducts themselves would “breathe” air out through the insulation layer. I explained that fiberglass insulation is designed to trap heat—not to allow airflow. The structure is dense enough that while air doesn’t move freely through the fibers, warm or cool air inside the duct stays inside. Leakage only happens if there are gaps, tears, crushed insulation, or poorly sealed vapor barriers. That’s why careful installation is so important. Fiberglass batts and rolls keep conditioned air moving inside the duct while providing an efficient shield around it.

How fiberglass insulation interacts with air

| Insulation Layer | Air Movement | Thermal Impact |

|---|---|---|

| Fiberglass Batts | None | Excellent |

| Vapor Barrier | None | Prevents moisture |

| Uninsulated Duct | Possible | Poor efficiency |

Fiberglass batts act as a barrier, not a channel for air.

Conclusion

Fiberglass insulation is a reliable, safe, cost-effective choice for air ducts. It prevents condensation and energy waste, provided it’s correctly installed and maintained.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions