White Fiberglass Insulation: What Makes It Different and How Should You Use It?

If you have seen unusual colors in insulation materials, you might wonder about the benefits or risks—white fiberglass especially draws attention.

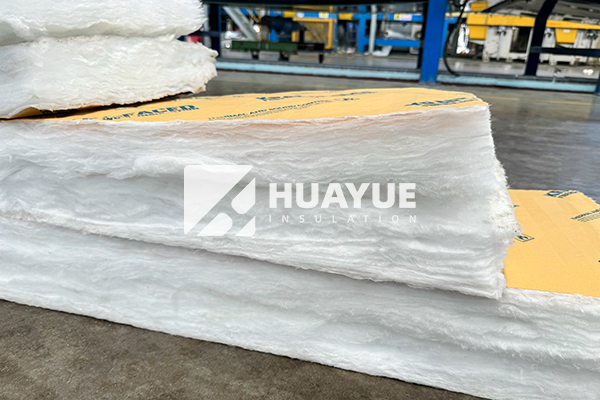

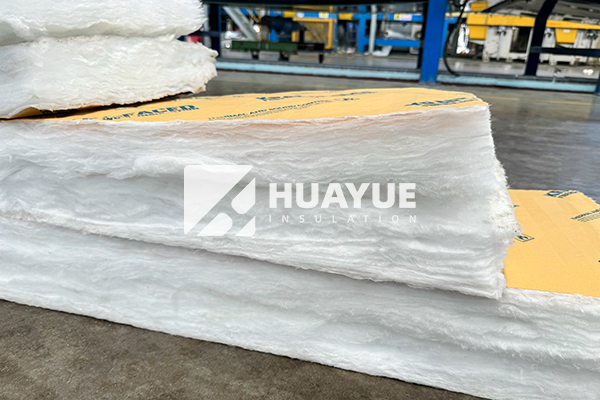

White fiberglass insulation is essentially a colorless, binder-free type of fiberglass that is used for specific applications where aesthetic, chemical stability, and purity are top priorities.

Many industrial and commercial users, including engineers and facility managers, often ask me about the details of this unique material. By understanding why white fiberglass exists and what purpose it serves, you can make better decisions for your project and avoid common pitfalls in material selection.

Is there white fiberglass insulation?

The sight of white fiberglass insulation raises questions. Is it a special product, or just regular insulation with a different color?

Yes, there is white fiberglass insulation. It is made without the yellowing binders or coloring agents found in traditional batts, which keeps it naturally white and pure.

The reason white fiberglass insulation is distinct comes down to its manufacturing process. Most fiberglass insulation on the market appears yellow or pink because of added binders or dyes. These chemicals help hold the glass fibers together and sometimes add branding color. But sometimes, end users such as chemical plants and processing facilities need an insulation that is as inert, clean, and non-reactive as possible. This is particularly the case in highly regulated environments, where even trace outgassing or binder fumes can compromise product quality or pose health risks. White fiberglass insulation is preferred in these industries because there is minimal chance of chemical contamination. It is also visually distinct, making quality checks easier.

I visited a chemical plant years ago where the process lines had to be covered only with white insulation. The engineers there said they had less worry about unexpected reactions and were more confident about the insulation holding up under demanding cleaning protocols.

| Feature | White Fiberglass Insulation | Traditional Yellow/Pink Fiberglass |

|---|---|---|

| Color | White (natural glass) | Yellow/Pink (dye/binder added) |

| Binder | Binder-free or clear | Phenolic-based or similar |

| Typical Application | Pharmaceutical, food, lab | General construction |

| Chemical Reactivity | Minimal | Can emit trace chemicals |

| Appearance Despite Aging | Remains white/clean | May yellow further over time |

What is white insulation used for?

People who are new to insulated industrial systems sometimes ask: why choose white insulation over traditional types? Does the color affect the functionality?

White insulation is used mainly in cleanrooms, laboratories, food processing, and pharmaceutical facilities, where the lowest possible chemical emission and cleanliness are required.

Choosing the right insulation for a critical environment takes more than just checking R-value. Individual industries put strict limits on what can go into their process environment. For pharmaceutical companies, for example, white fiberglass insulation is valuable because it does not add dust, particles, or any colored contaminants. Its binder-free nature means fumes and outgassing are not a concern. In cleanrooms, even a slight change in air quality can compromise months of research or ruin entire product batches. This is true for food processing, too—white insulation does not shed artificial colors or odors that could taint products.

I remember when one food processing client replaced some old yellow insulation with white fiberglass. The cleaning staff said that maintenance became simpler and faster. There was less need for special cleaning methods and fewer reports of strange odors or discolorations, even after hot washes or steam cleaning.

| Common Application Area | Reason for White Insulation |

|---|---|

| Pharmaceutical Plants | Purity, no outgassing |

| Cleanrooms | No fibers or chemical release |

| Food/Beverage Plants | No color/odor contamination |

| Hospitals, Labs | Particle-free, safe |

What is the biggest problem with fiberglass insulation?

Clients often ask if fiberglass insulation, white or otherwise, has flaws. No product is perfect, and knowing weaknesses is as important as knowing strengths.

The biggest problem with fiberglass insulation is that it can trap moisture if not installed correctly, which can lead to decreased insulation value and create conditions for mold or corrosion.

All fiberglass, including white types, has a structure that can allow water vapor to pass if the vapor barrier isn’t perfect. If moisture gets inside, it stays. Over time, wet fiberglass loses R-value and can start to slump or compress. In severe cases, the trapped moisture creates perfect conditions for mold to grow or can accelerate corrosion of metal pipes and tanks—especially dangerous in chemical plants. Since white fiberglass insulation is often used in clean or sensitive environments, keeping a flawless vapor barrier becomes even more important.

When I talk to plant engineers, we discuss inspection schedules and moisture sensors. It’s much easier to keep things dry in a food plant with good insulation practices and early leak detection. Prevention beats remediation every time. When problems with moisture pop up, whole sections of insulation usually have to be replaced, raising costs and downtime.

| Problem Area | Effect | Solution |

|---|---|---|

| Moisture intrusion | Lowers insulation value, causes CUI | Proper vapor barrier, routine inspections |

| Compaction/slumping | Reduced energy savings | Careful installation, low-traffic access |

| Fiber release | Airborne irritants | Proper cover, low-disturbance use |

Can I touch white insulation?

People are sometimes tempted to touch insulation in warehouses, attics, or mechanical rooms. Is it safe to handle white fiberglass without protection?

No, you should not touch white insulation with bare hands. Even though it is cleaner and binder-free, it is still made of fine glass fibers that can irritate your skin.

Fiberglass, regardless of its color, is made of tiny spun glass fibers. These fibers can cause itching, rashes, and in some cases, skin irritation if handled with bare hands. The white, binder-free version may shed particles more easily because binders are what typically hold fibers together firmly. Anyone who handles fiberglass insulation, white or otherwise, needs to wear gloves, long sleeves, and a mask, especially if there are large exposed areas.

I remember during a site walk-through, a project manager absentmindedly brushed his hand across exposed white fiberglass. He had red, itchy hands for days afterward. We always include PPE reminders in training, no matter how “clean” insulation looks. Safety has no shortcuts, even for visually appealing products.

| Common Handling Issue | Risk | Safety Precaution |

|---|---|---|

| Skin contact | Itching, minor skin rashes | Use gloves and protective wear |

| Breathing dust | Minor respiratory irritation | Wear a dust mask when handling |

| Eye contact | Irritation if fibers contact eyes | Use safety goggles if overhead |

Conclusion

White fiberglass insulation is a specialty product prized for its purity and cleanliness but requires careful installation and safety practices just like traditional fiberglass. Always match material to environment and handle safely.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions