Is Fiberglass Insulation Fire Resistant?

Are you concerned that the insulation in your walls could become a fire hazard? It’s a valid worry for any homeowner or project manager trying to ensure safety.

Yes, fiberglass insulation is fire resistant. The material itself is non-combustible because it is made from glass fibers. It is designed to slow the spread of fire, providing critical time for evacuation, rather than contributing fuel to a blaze.

Choosing the right materials is fundamental to building a safe structure. With over 30 years of experience in the thermal insulation industry, we’ve seen firsthand how crucial this choice is. As a company that manufactures and exports glass wool (fiberglass), rock wool, and other insulation products to over 100 countries, we understand the science behind fire resistance. Let’s explore why fiberglass is a trusted choice for fire safety.

Will Fiberglass Insulation Burn?

So, you get that it’s "fire resistant," but does that mean no part of it can ever burn? This is a common point of confusion that needs a clear answer.

The core glass fibers of fiberglass insulation will not burn; they will only melt at extremely high temperatures (around 1,000°F or 540°C). However, if the insulation has a paper or foil facing, that facing material can be combustible if not properly treated with fire retardants.

The Science Behind Fiberglass And Combustion

To truly understand why fiberglass doesn’t burn, we have to look at what it’s made of. The primary ingredient is sand, which is converted into glass. Think about it: sand doesn’t burn on a beach, and glass doesn’t catch fire in your oven. The process involves melting sand and other minerals and then spinning them into fine, flexible fibers. These fibers are inherently non-combustible. There is simply no chemical reaction with oxygen that would produce a flame. The binding agent used to hold the fibers together can smolder or burn off at high temperatures, but it makes up a tiny fraction of the material’s mass and doesn’t sustain a fire. The real variable, as we mentioned, is the facing. Kraft paper facing is flammable, which is why it’s treated with fire-retardant chemicals. These chemicals are designed to slow ignition and the spread of flames, helping the entire product achieve a Class A fire rating. For maximum safety, using unfaced fiberglass insulation eliminates this variable completely.

What is the Composition And Historical Usage Of Fiberglass Insulation?

Ever wonder where this common pink or yellow insulation came from? Understanding its history and makeup gives you a better appreciation for why it’s a go-to material for modern construction.

Fiberglass is primarily made from spun glass fibers, held together with a binder. Its widespread use began in the 1930s as an effective and economical material for thermal and acoustic insulation, largely replacing less safe materials like asbestos over time.

Composition and Historical Development

The invention of modern fiberglass insulation was something of an accident. In the early 1930s, a researcher at Owens-Illinois accidentally directed a jet of compressed air at a stream of molten glass, creating a flurry of fine glass fibers. This led to the development of a commercial manufacturing process patented as "Fiberglas" in 1936. Its composition is simple yet effective: sand and recycled glass are melted and spun into fibers. A binding agent is added to hold the fibers together in batts or rolls.

Historically, its adoption was a major step forward in building safety and efficiency. Before fiberglass, materials like asbestos were common for insulation, but we are all now aware of its severe health risks. Other materials like cork or horsehair were also used but were less effective and often posed fire hazards. Fiberglass offered a solution that was not only an excellent thermal insulator but also inherently fire-resistant, non-corrosive, and resistant to moisture damage and pests. This unique combination of properties led to its rapid adoption in residential homes, commercial buildings, and industrial applications, a position it has maintained for nearly a century due to its proven performance and safety profile.

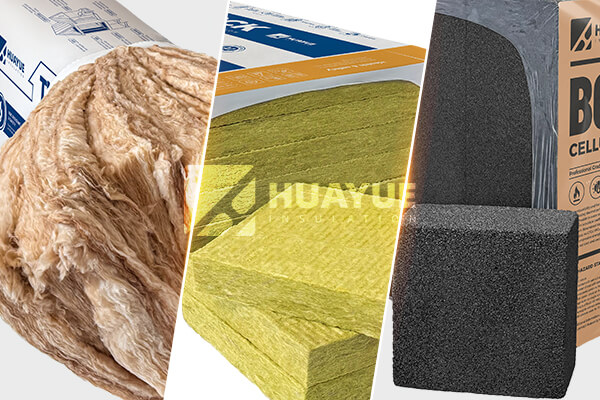

How Does Fiberglass Compare To Other Insulating Materials in Fire Resistance?

With so many insulation options on the market, how can you be sure you’re making the best choice for fire safety? It’s crucial to compare the performance of different materials directly.

Fiberglass and rock wool insulation are top performers as they are non-combustible. Foam-based insulations are combustible but treated with retardants, while cellulose is flammable by nature and relies heavily on chemical treatments for its fire resistance.

A Direct Comparison of Fire Performance

As a manufacturer providing a range of insulation solutions, including glass wool, rock wool, foam glass, and rubber foam, we guide clients through this decision daily. My client Hans, a plant engineer in Germany, needs the best possible protection for his chemical tanks, so this comparison is vital. Here’s how the materials stack up:

| Insulation Type | Base Material | Fire Resistance Characteristics | Key Considerations |

|---|---|---|---|

| Fiberglass (Glass Wool) | Spun Glass Fibers | Non-combustible. Will not burn, but melts around 1,000°F (540°C). Faced versions can have flammable components. | Excellent and cost-effective choice for most residential and commercial applications. |

| Rock Wool (Mineral Wool) | Volcanic Rock & Slag | Non-combustible. Has a much higher melting point than fiberglass, over 2,000°F (1,093°C). | Superior fire resistance. Often specified for fire-stopping applications and in high-risk environments. |

| Foam Glass | Recycled Glass | Non-combustible & Impermeable. Will not burn and does not absorb flammable liquids. Provides an excellent barrier against fire. | Premium choice for industrial tanks and critical applications where preventing Corrosion Under Insulation (CUI) and fire is paramount. |

| Spray Foam Insulation | Polyurethane | Combustible. It’s a plastic material that will burn and can release hazardous smoke. Requires a thermal barrier like drywall by code. | Must be correctly installed and covered. Its fire performance depends entirely on fire retardants and protective layers. |

| Cellulose Insulation | Recycled Paper | Combustible. The base material is flammable. Relies heavily on borate fire retardants, which can lose effectiveness if they get wet. | The fire resistance is an additive feature, not an inherent property of the material itself. |

For most standard projects, fiberglass offers a fantastic balance of safety and performance. For applications demanding the highest level of fire protection, rock wool or foam glass are superior alternatives.

Conclusion

To put it simply, fiberglass insulation is indeed fire resistant. Its core material will not burn, making it a safe and reliable component of a building’s fire protection system when installed correctly.

At HUAYUE, providing world-class insulation solutions since 1998 is our expertise. We are here to help you select the ideal material for your project, offering everything from glass wool to foam glass with custom solutions available.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions