Is Fiberglass Insulation Better Than Cellulose?

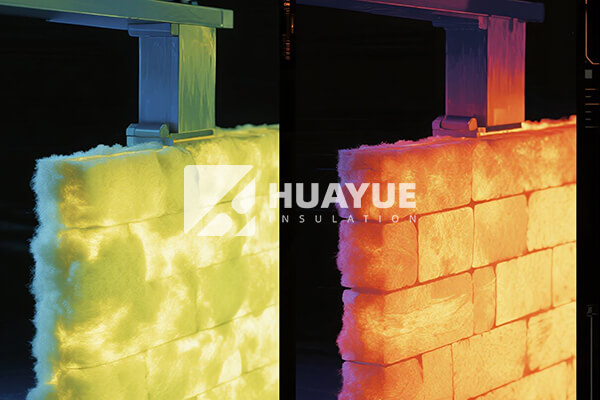

Stuck in the great debate between fiberglass and cellulose insulation? You’re not alone. It’s a classic matchup, and choosing between the fluffy pink stuff and the recycled grey material can be confusing for any homeowner or builder aiming for the best performance.

Neither insulation is universally "better"; the best choice depends on your specific project, budget, and priorities. Fiberglass excels in moisture resistance, ease of installation in open walls, and cost-effectiveness, while cellulose offers a slightly higher R-value per inch and superior air-sealing capabilities when dense-packed.

Making the right choice requires looking beyond the surface. As a manufacturer of world-class insulation materials like glass wool since 1998, we at HUAYUE have seen every type of application and understand the precise strengths and weaknesses of each material. This isn’t about picking a winner, but about matching the right product to the right job. Let’s break down the comparison so you can make an informed decision.

What is Fiberglass Insulation?

You’ve likely seen it before, but what exactly is that pink or yellow "cotton candy" in walls and attics? It’s one of the most common and recognizable building materials in the world.

Fiberglass insulation is a thermal and acoustic insulator made from extremely fine fibers of glass. These fibers are woven together and held with a binder to create a wool-like substance that can be formed into batts, rolls, or loose-fill for blowing into attics and walls.

Deeper Dive into Fiberglass

The name is very literal: it’s fibers of glass. The manufacturing process starts with sand and a large amount of recycled glass, which are melted together in a furnace at about 2500°F (1370°C). This molten glass is then spun at high velocity to create superfine filaments. A binder is applied to hold these threads together into a cohesive mat, which is then cured in an oven and cut into the familiar forms you see at the hardware store.

The key to its performance lies in its structure. The tangled mass of fibers creates billions of tiny air pockets. These pockets trap air, and since still air is a very poor conductor of heat, the insulation effectively slows heat transfer. Its main advantages stem from its core material: because it’s made of glass, it is naturally non-combustible and inorganic. This means it won’t burn, support mold growth, or serve as a food source for pests, making it an incredibly durable and stable material over the long term.

What is Cellulose Insulation?

Moving on to the other contender, what is the grey, almost papery-looking insulation? It’s often touted as the eco-friendly choice, but what’s it really made of?

Cellulose insulation is a type of thermal insulator made predominantly from recycled paper products, primarily ground-up newsprint. This paper is then heavily treated with chemicals, most commonly borates, to provide resistance against fire, mold, and pests.

Deeper Dive into Cellulose

Cellulose is one of the oldest forms of home insulation. Its modern form is manufactured by taking recycled paper, shredding it into fine pieces, and then milling it into a fluffy, low-density material. During this process, it is infused with fire-retardant chemicals like boric acid, sodium borate, and sometimes ammonium sulfate. These chemicals are crucial; without them, the insulation would essentially be flammable paper filling your walls. The borates serve a triple purpose: they make the paper fibers difficult to ignite, they are toxic to insects like termites and cockroaches, and they inhibit the growth of mold.

Unlike fiberglass, which can come in pre-cut batts, cellulose is almost always installed as a loose-fill product. It can be blown into an open attic to create a thick blanket, or it can be "dense-packed" into closed wall cavities. In this application, installers drill small holes and use a high-pressure machine to blow the cellulose in until it fills the entire cavity, minimizing air gaps.

Thermal Performance / R-Value

When it comes to performance, which material keeps you warmer? It’s a common question, as the primary job of insulation is to resist heat flow.

Cellulose has a slightly higher R-value per inch, typically around R-3.5 to R-3.7. Fiberglass insulation is very close behind, with an R-value of about R-3.1 to R-3.4 per inch. While cellulose wins on paper, installation quality has a bigger impact on real-world performance.

Deeper Dive into Real-World Performance

The R-value numbers seem close, so what’s the practical difference? The small advantage for cellulose means that for a given thickness, it will be slightly more effective. However, the true performance of an insulation system depends heavily on eliminating air leakage. This is where the installation method becomes critical.

When cellulose is dense-packed into a wall cavity, it fills every crack and crevice, creating a monolithic block that is very effective at stopping airflow (convection). This superior air sealing can give it a real-world performance advantage.

Fiberglass batts, on the other hand, must be cut and fitted perfectly around wires, pipes, and electrical outlets. Any small gap or compression of the batt creates a path for air leakage, which can significantly reduce its effective R-value. However, modern high-density fiberglass batts and advanced installation techniques have narrowed this gap. Furthermore, blown-in fiberglass in an attic offers performance very similar to blown-in cellulose. The takeaway is that while cellulose has a slight edge in R-value per inch, a meticulous fiberglass installation can perform just as well as a standard cellulose installation.

Which Insulation is Easier to Install?

You need to get the insulation into your walls, but which one presents a bigger challenge? The ease and complexity of installation can be a major factor in your decision.

For new construction with open walls, fiberglass batts are significantly easier and faster to install, making them a favorite for both professionals and skilled DIYers. For retrofitting existing walls, the blown-in application of either cellulose or fiberglass is a specialized job that requires professional equipment.

Deeper Dive into Installation Methods

The installation process is where these two materials truly diverge.

Fiberglass Batt Installation: This is a very straightforward process in open cavities. You measure the space, cut the batt to size with a utility knife, and press it into place. It’s a clean, fast, and relatively simple job that doesn’t require expensive machinery. This is why it’s the dominant choice in new home construction. However, the challenge is in the details—cutting perfectly around obstacles to avoid gaps and compression takes care and skill.

Blown-In Installation (Cellulose & Fiberglass): This method is used for both materials in attics and closed walls. It requires a large mechanical hopper and a long, powerful hose to blow the material into place. This is not a DIY-friendly task. Dense-packing cellulose into existing walls is particularly complex, as the installer must ensure the right density to prevent settling over time. While it’s a more involved process requiring a professional, it does a better job of filling irregular spaces than batts can. In an attic, blowing in either material is generally faster for a professional than installing hundreds of individual batts.

Side-By-Side Comparison

So, how do they stack up across the board? Let’s put them head-to-head on the key metrics that matter most to homeowners and builders.

Both materials are excellent insulators when installed correctly. Your choice often comes down to weighing factors like moisture resistance, cost, and specific application needs. Fiberglass is often preferred for its stability and moisture handling, while cellulose is chosen for its recycled content and air-sealing properties.

Deeper Dive into Key Differences

As a manufacturer that supplies materials for global projects, we help clients like Hans, a German plant engineer, make these comparisons daily. Here’s a detailed breakdown:

| Feature | Fiberglass Insulation | Cellulose Insulation |

|---|---|---|

| R-Value per Inch | ~R-3.1 to R-3.4 | ~R-3.5 to R-3.7 (Slightly Better) |

| Moisture Handling | Inorganic glass fibers do not absorb water and do not support mold growth. | Organic paper fibers can absorb water, which can lead to mold if the chemical retardants are overwhelmed. |

| Fire Resistance | Naturally non-combustible. Will not burn. | Relies entirely on chemical fire retardants. Can smolder if exposed to intense heat. |

| Air Sealing | Batts can leave gaps if not perfectly installed. | Dense-pack application is excellent at sealing air leaks. |

| Sound Dampening | Good | Excellent (Higher density is more effective) |

| Cost | Generally less expensive, especially for batts. | Moderately priced. Professional installation adds to the cost. |

| DIY Friendliness | Batts are very DIY-friendly. Blown-in requires a pro. | Blown-in applications require professional equipment and skill. |

| Eco-Friendly | Made with a high percentage of recycled glass. | Made with up to 85% recycled paper. |

Conclusion

Ultimately, the choice between fiberglass and cellulose isn’t about which is better, but which is right for you. Fiberglass offers unmatched moisture resistance and value, while cellulose excels at air sealing.

With our extensive experience since 1998, HUAYUE Group can provide the ideal insulation solution for your project, from our world-class glass wool to rock wool and more. We deliver customized solutions to over 100 countries.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions