Is fiberglass batt better than spray foam?

Feeling overwhelmed about which insulation is right for your project? Many people just want the answer that’s reliable, proven, and won’t break the bank.

Fiberglass batt insulation is often considered a safer, more cost-effective, and reliable choice compared to spray foam, with easier installation and broad market acceptance.

Choosing insulation isn’t just about the R-value or price tags. Safety, durability, and ease of handling are all part of the picture. I often get asked this question by both my clients and my colleagues, especially those who are responsible for operating and maintaining large facilities. Let’s walk through the most common concerns, one by one, to see where the real advantages lie.

What are the disadvantages of fiberglass batt insulation?

Managing insulation projects can be stressful, especially with so many options. If you’re considering fiberglass batt, it’s good to understand its limitations.

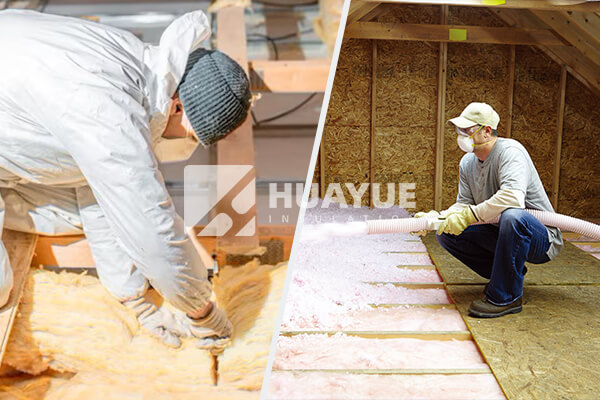

Fiberglass batt insulation can lose effectiveness if compressed, and improper installation may leave gaps, reducing energy efficiency. Handling can irritate skin and lungs without protective gear.

However, as I’ve found in many projects, most drawbacks like irritation or minor inefficiencies are easily managed with good PPE and trained installers. The key issues arise when installers rush or skip details, leaving air gaps or compressing the material. Here’s a simple look at the trade-offs:

| Disadvantage | How to Manage |

|---|---|

| Potential for gaps | Careful fitting and good workmanship |

| Skin/lung irritation | Use gloves, long sleeves, respirators |

| Lower R-value/inch | Use thicker batts or double layers |

| Water absorption | Keep dry and use vapor barriers |

In my experience, these risks have well-known and proven solutions. Compared with newer products with unknown long-term concerns, fiberglass is predictable and reliable.

Is foam board or batt insulation better?

Deciding between foam board and batt insulation can be confusing. Each has its fans and critics.

Foam board provides higher R-value per inch and resists moisture better, while fiberglass batt is more affordable and fits complex spaces more easily.

Both foam board1 and fiberglass batt2 have their ideal use cases. I reach for foam board in places where space is tight or exposure to moisture is likely, like basement walls or under slabs. Yet foam boards can be harder to install in irregular cavities or around pipes and wires. If I’m insulating large, open walls or attic floors, batts are much faster to install and can better fill long, irregular spaces. Maintenance is easier for batts, too, since damaged sections can be replaced without opening up everything. For most of my industrial projects, I use both, depending on the area and priorities.

| Factor | Foam Board | Fiberglass Batt |

|---|---|---|

| R-value/inch | High | Moderate |

| Price | Higher | Lower |

| Moisture | Resists well | Needs vapor barrier |

| Installation | Rigid | Flexible |

| Sound Control | Not as good | Excellent |

| Fire Resistance | Fair | Excellent |

There’s no single winner—just the right tool for each situation.

Why don’t banks like spray foam insulation?

Bank financing can put unexpected roadblocks in your building plans. I see this issue pop up, especially with older homes.

Banks often dislike spray foam insulation due to concerns about hidden damage, fire safety uncertainties, and difficult removal during structural inspections or repairs.

Spray foam forms an airtight seal that is great for energy bills, but it can also trap moisture or hide problems, especially in wood-framed structures. I’ve had colleagues whose property sales were delayed when lenders required detailed inspections to check if spray foam covered electrical, plumbing, or old rot. In some cases, lenders also worry about the fire rating of certain spray foam formulations, requiring extra certification paperwork. This can slow down financing or force homeowners to take costly steps to prove compliance. With fiberglass batt, these issues are rare, and the insulation type itself almost never triggers a red flag.

| Reason | Effect |

|---|---|

| Hidden damage risk | More inspections needed |

| Hard to remove/inspect | Complicates repairs |

| Fire safety uncertainty | Additional paperwork/cert. |

| Market unfamiliarity | Increased risk assessment |

Choosing materials with broader market and lender acceptance can help projects move smoothly from start to finish.

Does spray foam insulation cost more than batt insulation?

Budget is usually the first concern when making a big insulation decision. I hear this all the time from project managers.

Spray foam insulation is significantly more expensive than fiberglass batt, both for materials and installation labor, sometimes costing twice as much or more for the same area.

When I do my project estimates, spray foam almost always comes out as the high-cost option. Not only is the material itself expensive, but you also need trained crews and equipment to apply it safely. By contrast, fiberglass batts are mass-produced, easy for even small crews to install, and don’t require specialized tools. If a problem arises later, repairs are less expensive, too. For projects with tight budgets or when the ROI matters, batt insulation justifies itself with every quote.

| Insulation Type | Material Cost | Install Cost | Total Typical Cost (per m2) |

|---|---|---|---|

| Fiberglass Batt | ★ | ★ | $ |

| Spray Foam | ★★★ | ★★ | $$$ |

| Foam Board | ★★ | ★★ | $$ |

If I need quick, predictable, low-cost performance, batt insulation is my go-to recommendation.

What is the biggest problem with fiberglass insulation?

Every insulation material has its Achilles’ heel. For fiberglass, installers and customers often focus on this one main issue.

Improper installation of fiberglass insulation can leave gaps and reduce effectiveness, leading to heat loss and higher energy bills.

When I visit job sites, I see fewer problems with the insulation itself and more with rushed or careless jobs. Batt insulation needs to be cut to fit snugly around pipes, wires, and irregular spaces. If it’s compressed or left with gaps, its insulation value drops fast. Fortunately, these problems are easy to solve with basic training and attention. When installed right, fiberglass batt can work for decades without trouble.

| Problem | Cause | Solution |

|---|---|---|

| Gaps in coverage | Poor fit | Careful cutting/fitting |

| Compressed batts | Overstuffed | Proper installation |

| Moisture issues | Water leak | Vapor barrier, dryness |

Workmanship matters more than the material formula with fiberglass batts.

What is better, spray foam or fiberglass?

I get this question from clients who want the simple answer. The truth is, “better” depends on what you value most.

Spray foam has higher R-value and seals air leaks, but fiberglass batt is safer, more cost-effective, and easier to install or repair.

Spray foam is unbeatable for air sealing and tight spaces. However, I have seen its high cost, demanding application process, and long-term uncertainty turn project budgets upside down. Fiberglass, with decades of proven performance, shines in projects where low risk, speed, and flexibility matter most. Fire resistance is another overlooked bonus — fiberglass does not burn, so it provides extra time in an emergency. I always explain these trade-offs to my clients, and most choose fiberglass for its balance of safety, long-term performance, and cost.

| Factor | Spray Foam | Fiberglass Batt |

|---|---|---|

| Air sealing | Excellent | Fair |

| Fire safety | Moderate | Excellent |

| Long-term performance | Good | Excellent |

| Repairability | Poor | Excellent |

| Cost | High | Low |

Choose based on your project’s needs, but don’t overlook safety, cost, and long-term flexibility.

Is foam board better than fiberglass?

For projects where moisture or compression is a major issue, people often bring up foam board as an alternative to fiberglass.

Foam board outperforms fiberglass in wet or tight spaces, but fiberglass batt offers better sound control, fire safety, and cost efficiency.

I’ve seen foam board used very successfully in basement walls, under slabs, or exterior sheathing, where its moisture resistance and rigidity help a lot. But those same qualities make it harder to install in attics, wall cavities, or around lots of utilities. Fiberglass fills irregular spaces easily and costs much less. Plus, its sound-dampening quality gives added comfort in buildings with lots of equipment noise. If you ask what’s “better,” it still comes down to matching the material to the space. There are few one-size-fits-all answers in insulation.

| Situation | Foam Board Benefit | Fiberglass Benefit |

|---|---|---|

| Wet environment | Doesn’t absorb water | Needs vapor barrier |

| Odd shapes | Difficult to fit | Flexible, fits anywhere |

| Large surfaces | Sturdy, easy layers | Fast, simple install |

| Fire exposure | Some types combustible | Non-combustible |

I decide case by case, but for flexibility and price, fiberglass is usually ahead.

Why is batt insulation so expensive?

Many people assume batt insulation should be the cheapest option, but sometimes prices seem high.

Batt insulation can seem expensive due to production costs, market demand, and transport, but it remains more cost-effective than spray foam or custom solutions.

When I talk to procurement teams, they’re often confused by fluctuating insulation prices. Raw material prices, factory costs, and logistics all add up, but with the scale of production, batt insulation still holds a price advantage over more specialized types. While initial prices may jump due to fuel or supply chain issues, the simple installation and low maintenance make fiberglass batt one of the best values over the life of a building.

| Cost Factor | Impact Level |

|---|---|

| Raw material cost | High |

| Transport/logistics | Medium |

| Manufacturing scale | Lowers cost |

| Labor to install | Low |

Costs are rarely static, but batt insulation remains the most widely available and competitively priced mainstream option.

What is the best alternative to spray foam insulation?

Looking for a high-performance option without the drawbacks of spray foam? There are strong alternatives available.

Fiberglass batt insulation is often the best alternative to spray foam, offering proven performance, fire safety, and ease of installation at a much lower cost.

I always come back to fiberglass batt when reliability, safety, and broad market acceptance matter most. The material has decades of data behind it and is trusted by builders worldwide. For most commercial, residential, and industrial projects, it provides excellent thermal and acoustic control. If you want to get more specialized, mineral wool or newer composites add extra performance but at higher prices. The trade-off usually points to batt insulation for most demanding customers. That’s why I see it as the smart, low-risk, high-value solution for the majority of my projects.

| Alternative | Pros | Cons |

|---|---|---|

| Fiberglass Batt | Low cost, fire safe, proven | Gaps possible, itchy |

| Mineral Wool | Fire safe, better acoustics | More expensive |

| Foam Board | Moisture proof | Hard to install |

Choose the option that matches your needs, but fiberglass batt often hits the sweet spot for most users.

Conclusion

Fiberglass batt is the smart, reliable, cost-effective choice for insulation, offering proven performance, safety, and flexibility where spray foam and foam boards fall short.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions