How Do You Choose the Right Fibreglass Wool Factory?

When you start a new insulation project, it can be overwhelming to choose the right manufacturer. Too many claims, confusing specs, and you are worried about quality and safety.

A trustworthy fibreglass wool factory should offer a wide product range, make reliable promises about quality and safety, and have experience meeting strict international standards. With the right partner, you save time, money, and avoid headaches down the road.

You want the best for your building–and you need more than just promises. I have worked with many insulation factories, and learned the small details matter. The true test of a supplier is how they handle customization and special requirements. Let me help you figure out how to choose a real industry leader.

What is Fiberglass Wool?

So much confusion out there: everyone says their material is the best, but what really is fiberglass wool?

Fiberglass wool is a man-made fiber insulation. It is made by melting sand and recycled glass, then spinning it into fibers. This creates a soft, wool-like texture ideal for thermal and sound insulation.

Fiberglass wool is not just cotton candy-like fluff. It is created by combining silica sand, recycled glass, and other raw materials in a furnace. The molten mixture is transformed into thin fibers using a spinning process. These fibers get bonded together using special binders—sometimes formaldehyde-free, which many markets now require.

Here is a helpful breakdown of how it is made:

| Step | Details |

|---|---|

| Raw Materials | Silica sand, recycled glass, soda ash |

| Melting | Heated over 1,000°C to form molten glass |

| Spinning | Centrifugal force spins glass into fine fibers |

| Binding | Fibers bonded using proprietary resin |

| Shaping | Made into rolls, batts, boards, or pipe |

| Cutting | Sized for various insulation applications |

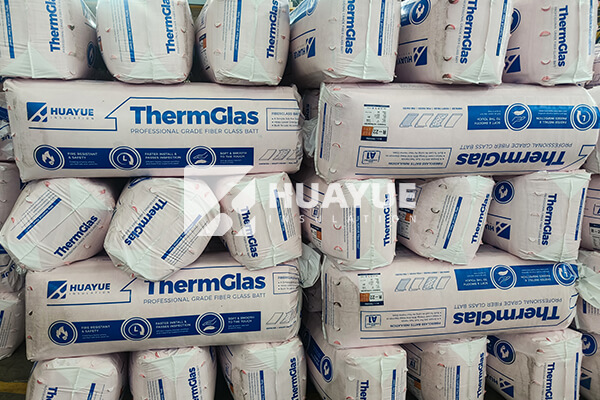

The product’s shape can be changed. You get boards, batts, rolls, and even pipe insulation. HUAYUE, since 1998, covers all these variations and offers several types of facings to suit your needs. For overseas buyers needing North American, Australian, or New Zealand market standards, you can get custom R-values and even formaldehyde-free products. This kind of flexibility matters for big jobs.

Is Fiberglass Wool Safe?

Every engineer is asked: Is fiberglass wool safe to use in my project?

Fiberglass wool is safe when installed and handled properly, especially modern products that follow strict safety regulations. Look for non-formaldehyde and certified insulation for peace of mind.

When choosing insulation, health and safety come first. Fiberglass wool used to have a bad reputation, mostly because early binders contained formaldehyde and the fibers could irritate skin. Now, leading manufacturers like HUAYUE have switched to friendly manufacturing. Products come with ISO, CE, SGS, and even R-value certification for export markets.

Safety features to look for include:

| Safety Feature | Importance |

|---|---|

| No Added Formaldehyde | Reduces VOCs, safer indoor air |

| Dust Suppression | Easier to handle, less irritation |

| Fire Resistance | Will not burn, meets building code requirements |

| Certification (ISO, CE) | Verified by trusted third parties |

| Moisture Resistance | No mold, higher durability |

I always check for detailed certifications before buying. For those in Europe and North America, clear certification is not a “nice to have”—it is the law. Professional insulation suppliers go further by using low-emission resins and documentation for each batch. Ask to see them.

High-Quality Fiberglass Wool Insulation for Superior Thermal Performance?

With rising energy costs, you need insulation that performs at the highest standard.

High-quality fiberglass wool insulation delivers excellent thermal performance, with customizable R-values and moisture resistance. This makes it ideal for a range of climates and strict building codes.

I have seen the difference between cheap and top-quality glass wool. Bad insulation leads to sagging batts, unhappy clients, and wasted energy costs. HUAYUE manufactures glass wool with stable fiber structure and high elasticity. This means their products keep their shape longer, give real R-values, and fit tight with no air gaps.

What sets high-performance fiberglass wool apart is not just the thermal value printed on the bag. Let’s look at the must-have qualities:

| Feature | What to Look For |

|---|---|

| Consistent Density | No thin spots, even R-value |

| Compression Recovery | Returns to full shape after unpacking |

| Water Repellency | Specialized additives, stays dry |

| UV Resistance | Tough for exposed installations |

| Multiple Facings | Kraft, Foil, Glass Cloth for all needs |

A good supplier like HUAYUE offers full documentation, tailored facings, and even support for your logistics. Orders get shipped from near China’s biggest ports, so international delivery is quick and less risky.

Conclusion

Choosing the right fiberglass wool factory is about more than just price. Look for proven expertise, safety, and certified performance, and you will get insulation you can trust.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions