Fiberglass Metal Building Insulation: Is It the Best Choice for Modern Facilities?

Painful heat loss and energy costs can drain your business. If you own or operate a metal building, you know poor insulation drives up bills, hurts comfort, and can even damage your equipment.

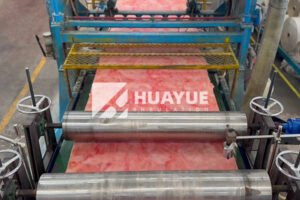

Fiberglass insulation is commonly used to insulate metal buildings because it is affordable, easy to install, and offers reliable thermal protection. It helps maintain consistent temperatures and cuts energy expenses.

Metal buildings have unique building challenges. Traditional insulation methods do not always work, and installation mistakes can lead to increased energy loss or moisture problems. If you want to make your building safer, more efficient, and longer-lasting, you need insulation that fits metal buildings. Keep reading, and I’ll break down my experience with fiberglass, and why it might be the right—or wrong—choice for you.

Can you insulate a metal building with fiberglass insulation?

Cold drafts, condensation, and rattling noise make metal buildings uncomfortable and hard to work in. You might wonder if fiberglass insulation can solve all those problems.

Yes, you can insulate a metal building with fiberglass insulation. Fiberglass batts and rolls can fit between wall studs and roof purlins, providing effective thermal and sound insulation for most metal buildings.

How Does Fiberglass Insulation Fit into Metal Building Construction?

Insulating a metal building requires more than stuffing material in the walls. The unique steel construction calls for insulation that adapts to its shape and use. I have worked on projects where fiberglass batts quickly fit into wall cavities and under roof panels. It cushions temperature swings and keeps humidity under control. To use fiberglass, I measure cavity spaces, cut the rolls or batts to fit, and secure them with pins or wires. Details matter—like leaving no gaps, overlapping seams, and using sealant tape. I always recommend using facing material on fiberglass to help block moisture. That detail makes the insulation last longer and gives a neat finish. If the space is open, I sometimes use higher-density batts. For ceiling spaces, I layer the insulation for higher performance. See below the typical placement methods:

| Area | Method | Facing Needed | Notes |

|---|---|---|---|

| Wall Cavities | Batt/Roll, Pin, Wire | Yes | Prevent air gaps |

| Roof Purlins | Roll/Batt, Pin | Yes | Overlap seams, tape edges |

| Ceiling Space | Multiple Layers | Yes | Higher R-values if needed |

Good installation keeps the building warmer in winter and cooler in summer. It also dampens outside noise and gives the space a professional finish.

What is the best insulation to put in a metal building?

Choosing insulation feels tough. You see foam, fiberglass, mineral wool, and more—all claiming to be “the best.” Each has strengths, and picking the wrong one can mean wasted money and trouble later.

Fiberglass batt insulation is a popular choice for metal buildings because it is affordable and easy to install. Other top options include spray foam, rock wool, and foam glass, which offer better moisture resistance and higher R-values.

Comparing Common Insulation Options for Metal Buildings

Different insulation materials have different properties. I have installed fiberglass many times for clients who want quick, affordable upgrades. But for people who need custom solutions—like Hans Müller in his chemical plant—I also look at spray foam, foam glass, and mineral wool. Spray foam sticks to metal surfaces but costs more and needs experienced installers. Foam glass is strong against moisture and lasts longer, but it takes more engineering and budget. Mineral wool resists fire and moisture but needs special handling. For a quick comparison, here’s a simple table:

| Insulation Type | R-value/in | Moisture Resistance | Fire Resistance | Cost | Main Advantage |

|---|---|---|---|---|---|

| Fiberglass Batt | 2.9–3.8 | Moderate | Moderate | Low | Low cost, easy install |

| Spray Foam | 6.0–6.5 | Excellent | Good | High | Best air/vapor seal |

| Foam Glass | 3.2–3.4 | Excellent | Excellent | High | Long lifespan, water-proof |

| Mineral Wool | 3.7–4.2 | High | Excellent | Medium | Superior fire/moisture |

I always ask clients about their long-term plans and budget. For general warehouse or workshop use, fiberglass is often the first choice. If corrosion, fire safety, or moisture are top concerns, foam glass or mineral wool may offer better performance.

What is a disadvantage of fiberglass insulation?

You want insulation to last and keep working no matter what. But not every material is perfect. Even widely used fiberglass has problems.

A disadvantage of fiberglass insulation is that it can absorb moisture, which may cause mold, mildew, or corrosion in metal buildings. Poor installation can create gaps, reducing insulation efficiency.

Why Moisture Matters Most with Fiberglass

Fiberglass is made from spun glass fibers. It looks fluffy and light, but can attract moisture easily. When that happens, it gets heavy and loses its heat-blocking power. I have seen old warehouse walls with mold because fiberglass was not properly sealed. Wet insulation sags. It also starts smelling and attracts pests. If water condenses inside wall cavities, metal can corrode hidden by insulation. That’s a big problem for chemical plants and food storage. When choosing fiberglass, I always recommend using vapor barrier facings or sealant tape to keep water out. If the building is in a humid climate or will experience heavy condensation, alternative materials like foam glass should be considered. Long story short: fiberglass is easy to install, but it only performs well if kept dry—otherwise you may face expensive repairs and health risks.

What is a good R-value for metal building?

Figuring out the right R-value means more comfort and lower bills. If R-value is too low, inside temperatures swing fast and energy gets wasted.

A good R-value for metal building insulation usually falls between R-13 and R-30, depending on climate, building use, and local energy codes.

Matching R-values to Metal Buildings

R-value measures how well insulation resists heat flow. The larger the number, the better the protection. For metal buildings, I usually start with R-13 for walls and R-19–R-30 for roofs or ceilings. Colder regions may need higher values. I check local codes and ask customers about their heating and cooling needs. Sometimes, energy audits reveal weak points in the building envelope. In new projects, I usually recommend going above minimum code. That saves energy and raises comfort. Proper installation is just as important—compressed or gapped insulation won’t reach its rated R-value. Table below sums up common guidelines:

| Location | Suggested R-value | Comments |

|---|---|---|

| Walls | R-13 to R-19 | Most areas, higher better |

| Roof/Ceiling | R-19 to R-30 | Cold climates need higher |

| Doors | R-7 to R-15 | Specialty insulated doors |

Choosing the right R-value depends on your budget, climate, and goals. In my experience, higher R-values pay off in colder regions or facilities with strict temperature control needs like labs and storage areas.

Do you need a vapor barrier when insulating a metal building?

Moisture sneaks into buildings and causes hidden damage. For metal buildings, uncontrolled wetness can ruin insulation, invite corrosion, and hurt air quality.

Yes, you need a vapor barrier when insulating a metal building. A vapor barrier prevents moisture from passing through the insulation and reaching the metal, avoiding condensation and long-term damage.

Why Vapor Barriers Matter for Metal Buildings

Metal surfaces sweat when inside air meets cold outside air. This condensation creates invisible moisture problems. I have seen insulation rot and steel rust because installers skipped vapor barriers. When using fiberglass, always install facing or separate vapor barriers on the warm side of the insulation. In climates with humid summers and cold winters, the risk is even higher. Vapor barriers block airborne moisture and protect insulation. They also keep the building envelope healthier. If there are ceiling pipes, make sure to wrap and seal the insulation tightly. Here’s a quick reference table:

| Moisture Problem | Vapor Barrier Needed | Notes |

|---|---|---|

| High Humidity | Yes | Use foil or plastic facing |

| Occasional CUI | Yes | Tape all seams and joints |

| Dry Climate | Optional | Use facing for dust control |

When clients ask me about vapor barriers, I always say: better safe than sorry. It costs little, saves money, and makes insulation last long.

Conclusion

Fiberglass insulation works well for metal buildings if installed correctly with vapor barriers, the right R-value, and moisture protection for long-lasting comfort and lower costs.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions