Fiberglass Insulation with Vapor Barrier: Essential Choices for Moisture Control?

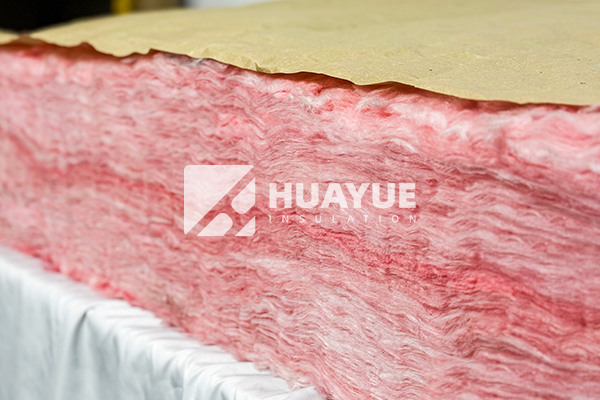

Condensation and mold threaten the integrity of any structure. Choosing the right vapor barrier for fiberglass insulation solves real problems before they begin.

A vapor barrier prevents moisture from moving through fiberglass insulation, stopping condensation and keeping buildings dry. The barrier goes on the warm side of the insulation, facing living spaces.

Some choices in building design seem easy but have lasting effects. Vapor barriers often fall into that category. There are so many different climates, materials, and installation needs. I learned early on that small decisions about vapor barriers can stop headaches years later. From humid summers to cold winters, the correct choice protects basements, tanks, and ceilings from costly damage. Let’s look deeper at how, when, and where to use fiberglass insulation with a vapor barrier.

When to use a vapor barrier with insulation?

Moisture damage is costly. Many people don’t know when to add a vapor barrier. If you install fiberglass insulation in places with high humidity or temperature differences, the vapor barrier becomes necessary.

A vapor barrier is best used when humidity inside the building is higher than outside, or where condensation often happens. In basements, crawl spaces, and humid climates, vapor barriers offer vital protection.

Moisture moves from warm areas toward cooler spaces. That moisture can collect inside insulation and cause mold, rot, and lowered performance. In cold regions, warm indoor air meets cold wall surfaces, creating condensation behind insulation. If I skip the vapor barrier, insulation can trap moisture, losing its function and damaging walls. In hot, humid climates, outside air can bring moisture into cool air-conditioned spaces. Both cases need vapor barriers. Table 1 summarizes practical uses for vapor barriers in common settings.

| Building Area | Recommended Vapor Barrier? | Reason |

|---|---|---|

| Basement Wall | Yes | Prevents ground moisture entering insulation |

| Exterior Wall (Cold) | Yes | Stops indoor humidity from condensing in wall |

| Interior Wall (Warm) | Usually no | Seldom has large temperature/humidity difference |

| Attic (cold climates) | Yes | Prevents indoor air condensing on cold roof |

| Commercial Metal Building | Yes | Reduces risk of ceiling and wall condensation |

What side of insulation does the vapor barrier go on?

Incorrect vapor barrier placement is a common mistake. Most guidelines are clear—the vapor barrier should face the warm side of the structure.

The vapor barrier must be installed on the side facing where the warm air will be. Usually, this is the inside surface for heated spaces.

Warm air carries moisture, and when it moves toward cooler areas, it drops the moisture. If the vapor barrier is on the wrong side, moisture will pass through and may get trapped. That is why, in northern climates where heating is used, the vapor barrier faces the interior. In hot climates with cooling, placement changes. It can sometimes face the exterior to prevent humid outdoor air from entering. I always check the building’s usage, regional climate, and wall structure to decide. The table below shows proper vapor barrier placement for different applications.

| Application | Vapor Barrier Placement |

|---|---|

| Heated Home (Cold Region) | Inside, facing living space |

| Air-conditioned Buildings | Usually inside, may vary (consult code) |

| Basement Walls | Inside, facing room |

| Metal Buildings | Between insulation and warm side |

| Storage Tanks (Warm) | Between insulation and tank wall |

Fiberglass Insulation with Vapor Barrier for Basement

Basements are often the dampest areas in any building. Moisture travels from the ground, pushing through walls. Fiberglass insulation with a vapor barrier solves many basement problems.

For basements, use fiberglass insulation with a vapor barrier facing indoors to stop ground-based moisture from entering living spaces.

A good basement stays dry and warm. I learned that unfinished basements collect water on the walls. If I used fiberglass without a vapor barrier, water could get trapped and lead to mold and a musty smell. With a vapor barrier sheet or foil facing inwards, I created a shield. This keeps ground water out and makes the space safer for storage or living. Local building codes may recommend different barrier materials. I always keep the vapor barrier unbroken. Joints and seams are sealed, not open. Proper installation means checking for continuous coverage—no gaps, no tears. If the basement is used as a living space, this step is even more important.

| Basement Use | Insulation Type | Vapor Barrier Required? | Placement |

|---|---|---|---|

| Storage/Laundry Room | Fiberglass Batts | Yes | Inward-facing |

| Finished Living Space | Fiberglass Batts or Panels | Yes | Inward-facing |

| Utility Vaults | Rigid Fiberglass Board | Yes | Facing toward room |

Vapor barrier between metal ceiling and fiberglass insulation?

Metal ceilings in industrial buildings create special insulation challenges. Vapor barriers reduce condensation that can form under and inside metal structures.

A vapor barrier should go between metal ceilings and fiberglass insulation whenever temperature differences or high humidity levels exist.

Condensation likes to form on metal surfaces because they get cold fast, especially in large storage tanks or industrial buildings. Moisture trapped between insulation and metal can create problems like corrosion. That risk increases if the space below the ceiling gets humid or if the ceiling is colder than the room. My experience shows that putting a vapor barrier between the fiberglass and metal stops most problems. The barrier keeps warm, moist air from reaching the cold metal where it can condense. In many projects, this single step saves expensive repairs. It also holds insulation efficiency steady. Choosing the right barrier material (foil, plastic, or composite) and sealing every seam makes a difference. If I skip or misplace the vapor barrier in a metal ceiling system, condensation or corrosion comes back fast.

| Metal Ceiling Use | Insulation Type | Vapor Barrier Placement |

|---|---|---|

| Industrial Tank Roof | Fiberglass Roll | Between ceiling and insulation |

| Commercial Storage | Fiberglass Batts | Between ceiling and insulation |

| Production Plant Office | Faced Fiberglass | Face toward room, sometimes both sides |

Conclusion

Using fiberglass insulation with a vapor barrier keeps buildings dry and durable. Know the right placement, climate fit, and application for lasting results.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions