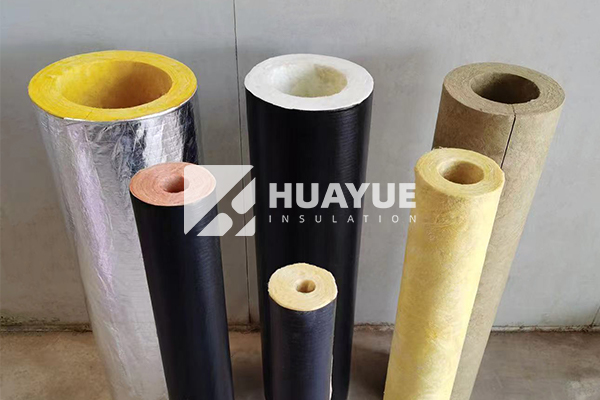

Fiberglass Insulation Pipe: Is It the Right Choice for Industrial Applications?

Modern industrial tanks face many threats, such as temperature loss and corrosion. I often get asked if fiberglass insulation pipes are really the best solution.

Fiberglass pipe insulation is reliable for thermal management, resisting high temperatures, providing fire safety, and performing well in both chemical and cryogenic tank settings. This makes it a strong contender for industrial needs.

Fiberglass insulation pipes can handle extreme heat, moisture, and daily wear in demanding settings. I have seen how effective they can be for both new and older tanks. But every material has limitations, so it’s important to look at both their strengths and their drawbacks before choosing.

Is fiberglass pipe insulation better than foam?

Fiberglass and foam insulation have different features, and each works best under specific conditions. Many industrial engineers ask which one performs better.

Fiberglass pipe insulation is preferred for high-temperature tanks and areas needing fire-safe, moisture-resistant protection. Foam insulation is often used for low-temperature and cryogenic applications. Fiberglass is less likely to burn and does not absorb water, making it safer for many tanks.

Fiberglass pipe insulation stands out because it does not burn or spread flames. I have seen customers choose it when open flames or hot surfaces are involved, especially in chemical facilities. Foam can have better cold resistance and prevent heat transfer at very low temperatures, but it may not handle high heat well. In areas with fire hazards, fiberglass keeps tanks and pipes safer. The table below shows a direct comparison between fiberglass and foam pipe insulation:

| Feature | Fiberglass Pipe Insulation | Foam Pipe Insulation |

|---|---|---|

| Temperature Range | -20°C to 400°C | -200°C to 120°C |

| Fire Resistance | Non-combustible | Can be combustible |

| Moisture Absorb | Low | Can absorb if not sealed |

| Compression | Good | Moderate |

| Cost | Moderate | Lower to moderate |

| Life Span | Long | Long |

I recommend fiberglass for fire-prone areas and foam for extra-low temperature settings unless moisture is a risk.

Is fiberglass pipe insulation good?

Fiberglass pipe insulation works well in many industrial settings. Customers often ask me if it’s as reliable as claimed.

Fiberglass insulation provides solid thermal performance, high fire resistance, and low moisture absorption, making it a strong and long-lasting material for protecting industrial pipes and tanks.

Fiberglass pipe insulation has served me and my clients in various chemical facilities and cold storage projects. Its structure resists damage from heat and moisture. Installers find it easy to fit and secure over long pipe runs. Unlike some materials, fiberglass does not sag or lose its insulating power over time. The core benefit I see is stability: it keeps temperatures steady and meets strict fire codes. It also reduces condensation, which protects pipes from corrosion under insulation (CUI). In places with intense heat or where fire risk is high, I trust fiberglass to keep tanks and equipment running safely and efficiently for years.

What is the temperature range for fiberglass pipe insulation?

Correct temperature management is a top concern in tank engineering. One question I frequently get is about the heat limits of fiberglass insulation.

Fiberglass pipe insulation can safely handle temperatures from about -20°C to 400°C (or -4°F to 752°F), making it suitable for many industrial heating and cooling applications.

Fiberglass stands out for its ability to perform over a wide temperature range. In my experience, this means it works equally well for steam pipes, chemical lines, and cryogenic tanks. At the lowest temperatures, it prevents heat loss and freezes. At the highest, it shields against dangerous surface heat. Other insulation materials like foam or rubber can break down or char at temperatures above 100°C. With fiberglass, I feel confident about long-term stability. This temperature span also meets most safety and compliance standards for regulated industries. For plant engineers like me, a proven temperature rating helps reduce maintenance worries and ensures assets last longer.

What is a disadvantage of fiberglass insulation pipe?

Fiberglass is not perfect. I always point out its weaknesses when customers compare insulation types.

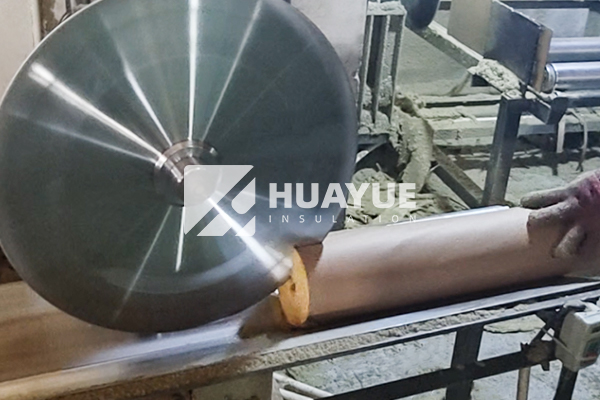

One main disadvantage of fiberglass insulation pipe is its brittleness, which makes it prone to breakage if handled roughly during installation or maintenance.

The rigid structure of fiberglass can crack if bent too sharply or dropped. I have seen installers struggle to fit it into tight corners and sometimes break pieces during adjustments. While fiberglass resists heat and moisture, it can still suffer mechanical damage. If chips or breaks happen, insulation performance may drop, and exposed areas could risk corrosion or temperature loss. Unlike flexible foam wraps, fiberglass seldom recovers from bends or pressure. Extra care during transport, storage, and fitting reduces breakage, but it adds time and cost. In heavy-use plants or those with many small bends, combining fiberglass with flexible sections may help. This way, plant engineers get the best thermal performance without constant repairs or replacements.

Conclusion

Fiberglass insulation pipe provides strong thermal protection and fire resistance for industrial tanks but needs careful handling because of its brittle nature.

You may also be interested in:

Ready to Get Started?

Get in touch with our experts for personalized solutions tailored to your needs.

Get Free QuoteLatest Articles

Let's Work Together

Ready to take your business to the next level? Get in touch with our team of experts and let's discuss how we can help you achieve your goals.

Get Free Solutions